A vehicle-mounted fully automatic intelligent hydraulic workover rig with tubing strings placed vertically

A tubing string, fully automatic technology, applied in the direction of drill pipe, casing, drilling equipment, etc., can solve the problems of high noise, high labor intensity, low mechanical efficiency, etc., to reduce environmental pollution, save workover sites, and improve work efficiency efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

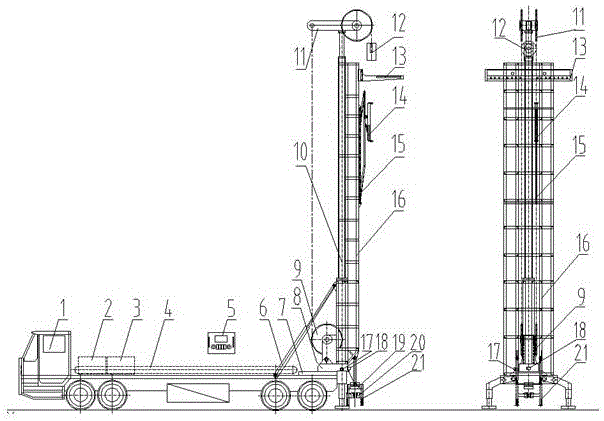

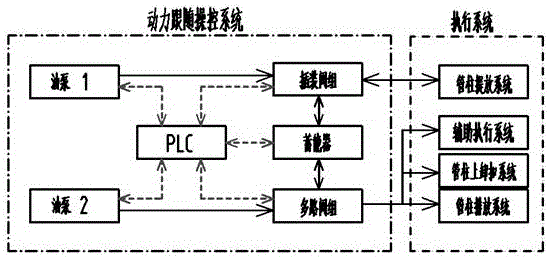

[0016] A vehicle-mounted full-automatic intelligent hydraulic workover rig for vertically placing tubing strings, which is composed of a vehicle-mounted chassis 1, a combined hydraulic power source 2, an intelligent power drive system 3, a hydraulic automatic energy storage system 4, an offline control panel 5, and a luffing cylinder 6 , fixed support 7, movable support 8, rope wheel distance increasing system 9, single-cylinder lifting system 10, balanced sky wheel system 11, automatic swimming lifting pipe system 12, pipe column discharge rack 13, automatic pipe grasping system 14 , automatic pipe transfer system 15, lifting support frame 16, wellhead automatic centering mechanism 17, tubing length automatic measuring mechanism 18, tubing automatic make-up and breakout device 19, tubing automatic wellhead plate 20, and multifunctional wellhead tubing seat 21. It is characterized in that the mechanism is divided into five major systems: vehicle luffing and support system, oil ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com