Solar cell with refractor

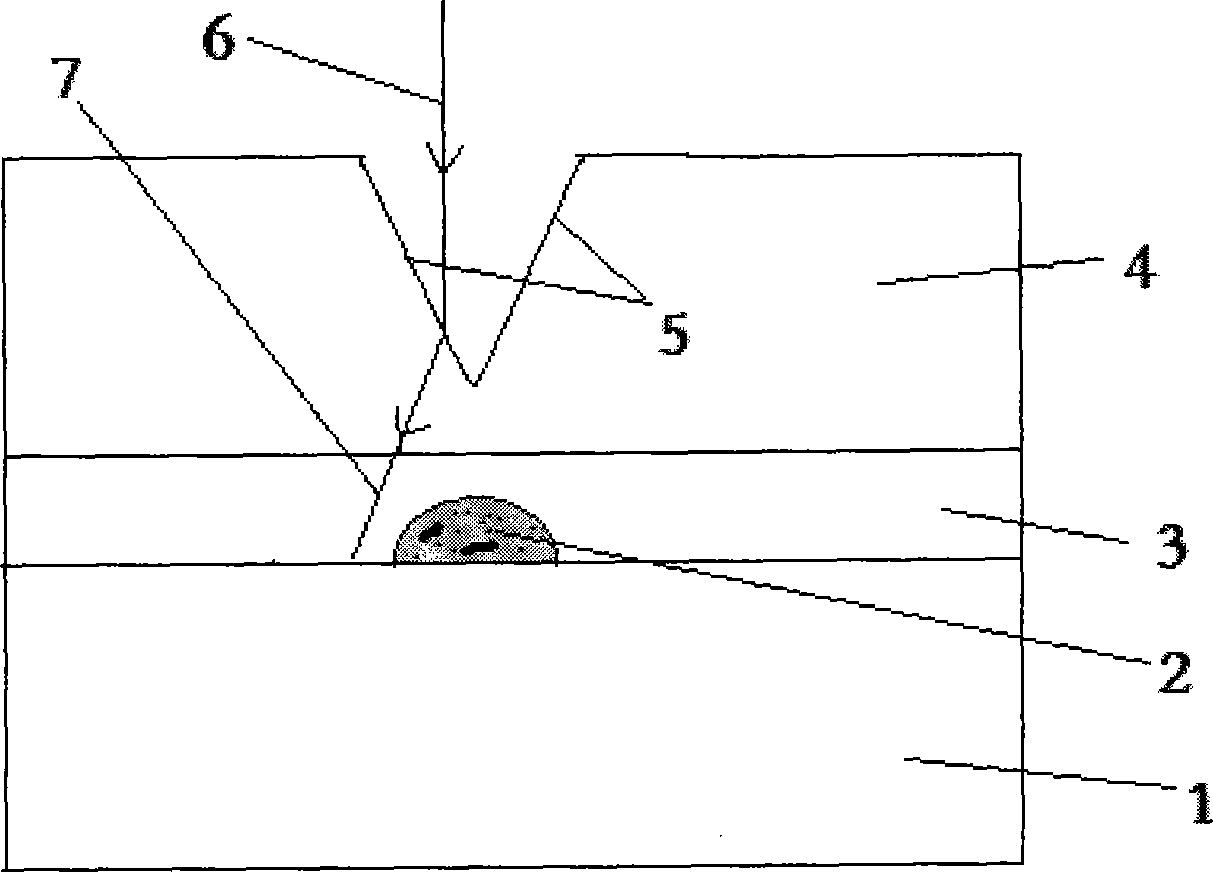

A technology of solar cells and refractors, applied in the field of solar cells, can solve the problems of reduced finger grid line width, expensive technology, and inability to completely eliminate them, and achieve the effect of increasing conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Step 1: Design and manufacture a front printing screen with alignment marks; the screen is a necessary material for printing solar cell electrodes, and generally consists of a screen frame, mesh cloth and adhesive film. And set the electrode pattern to be printed through the mesh and film. Here we design the front screen fingers with a width of 50 microns and a quantity of 80, and set three busbars evenly, and set an alignment point at the midpoint of each side in the printing area, so as to print the front electrode At the same time, the alignment standard is also printed and produced.

[0036] Step 2: preparing polysilicon cells and printing alignment points.

[0037]Select a P-type polycrystalline solar cell with a size of 156mm*156mm, and make front electrodes and alignment marks by screen printing, wherein the printed front finger grid lines have a width of 80 microns, a height of 15 microns, and a length of 153 mm. The number of front finger grid lines is 80, an...

Embodiment 2

[0043] Step 1: Design and make a front printing screen with alignment marks.

[0044] The screen plate is a necessary material for printing solar cell electrodes, and generally consists of a screen frame, mesh cloth and adhesive film. And set the electrode pattern to be printed through the mesh and film.

[0045] Here we design the front screen fingers with a width of 50 microns and a quantity of 80, and set three busbars evenly, and set an alignment point at the midpoint of each side in the printing area, so as to print the front electrode At the same time, the alignment standard is also printed and produced.

[0046] Step 2: preparing polysilicon cells and printing alignment points.

[0047] Select a P-type polycrystalline solar cell with a size of 156mm*156mm, and make front electrodes and alignment marks by screen printing, wherein the printed front finger grid lines have a width of 80 microns, a height of 15 microns, and a length of 153 mm. The number of front finger g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap