Black infrared reflection polyvinylidene fluoride (PVDF) solar cell rear panel composite film and manufacturing method thereof

A polyvinylidene fluoride, solar cell technology, applied in chemical instruments and methods, circuits, photovoltaic power generation, etc., can solve the problem of accelerating the thermal oxygen aging of polymer materials in the backplane, the heat storage temperature of the solar backplane film, and the film Problems such as poor dielectric breakdown characteristics, to achieve the effects of easy control, high solar coverage, and high infrared reflection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

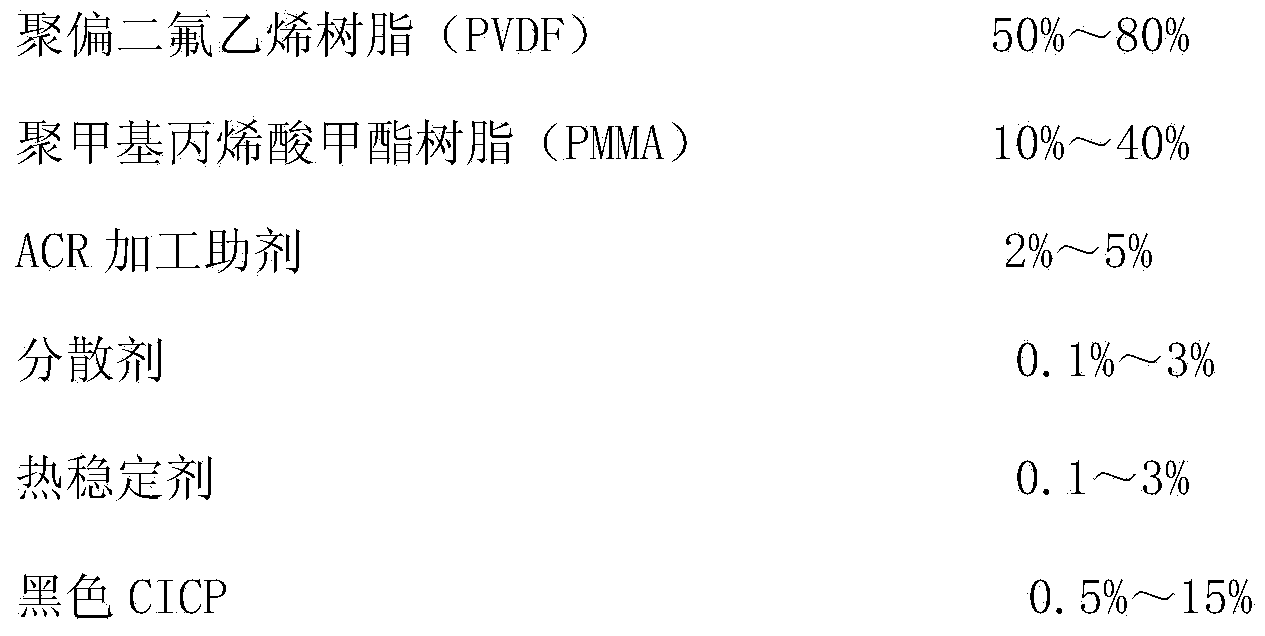

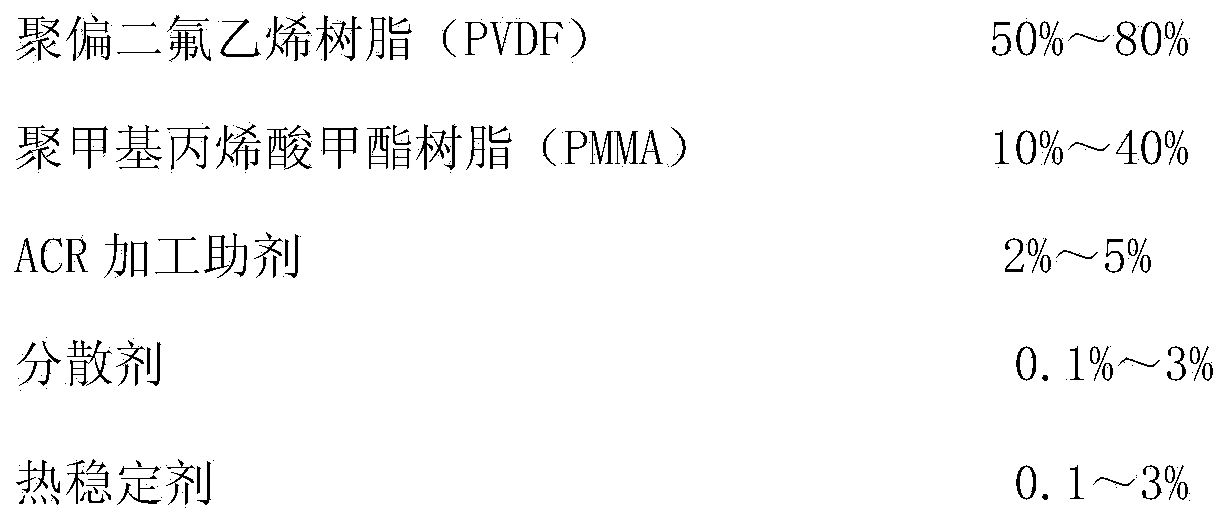

[0029] The components applied in the embodiments of the present invention are (but not limited to using the following components):

[0030] Black CICP: 10C909, black powder, total solar reflectance (TSR): 24%, average particle size 1.4μ. From the Shepherd Color Company in the United States, the surface is silanized before use.

[0031]Titanium dioxide: Ti-Pure350, nano-sized rutile titanium dioxide with an average particle size of 500nm, the surface has been treated with aluminum oxide, silicon dioxide and silanization, obtained from DuPont Company.

[0032] PVDF resin is a VDF homopolymer with a melt flow index of 8-15g / 10min (230°C, 5Kg), obtained from domestic Sanaifu Company.

[0033] PMMA resin: PLEXIGLS 8N, with a melt flow index of 3g / 10min (230°C, 3.8Kg), obtained from Evonik Rohm, Germany.

[0034] ACR process aid: P551 from Arkema.

[0035] Dispersant: N,N'-ethylenebisstearamide (EBS), melting point 130℃~145℃.

[0036] Heat stabilizer: rare earth / calcium / zinc com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com