Safe de-ironing conveyor belt

A conveyor belt and safety technology, applied in the field of safe iron removal conveyor belt, can solve the problems of reducing the service life of coal pulverizers, costing funds, and easily damaged coal pulverizers, etc., so as to improve service life, save electricity costs, and improve operation reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

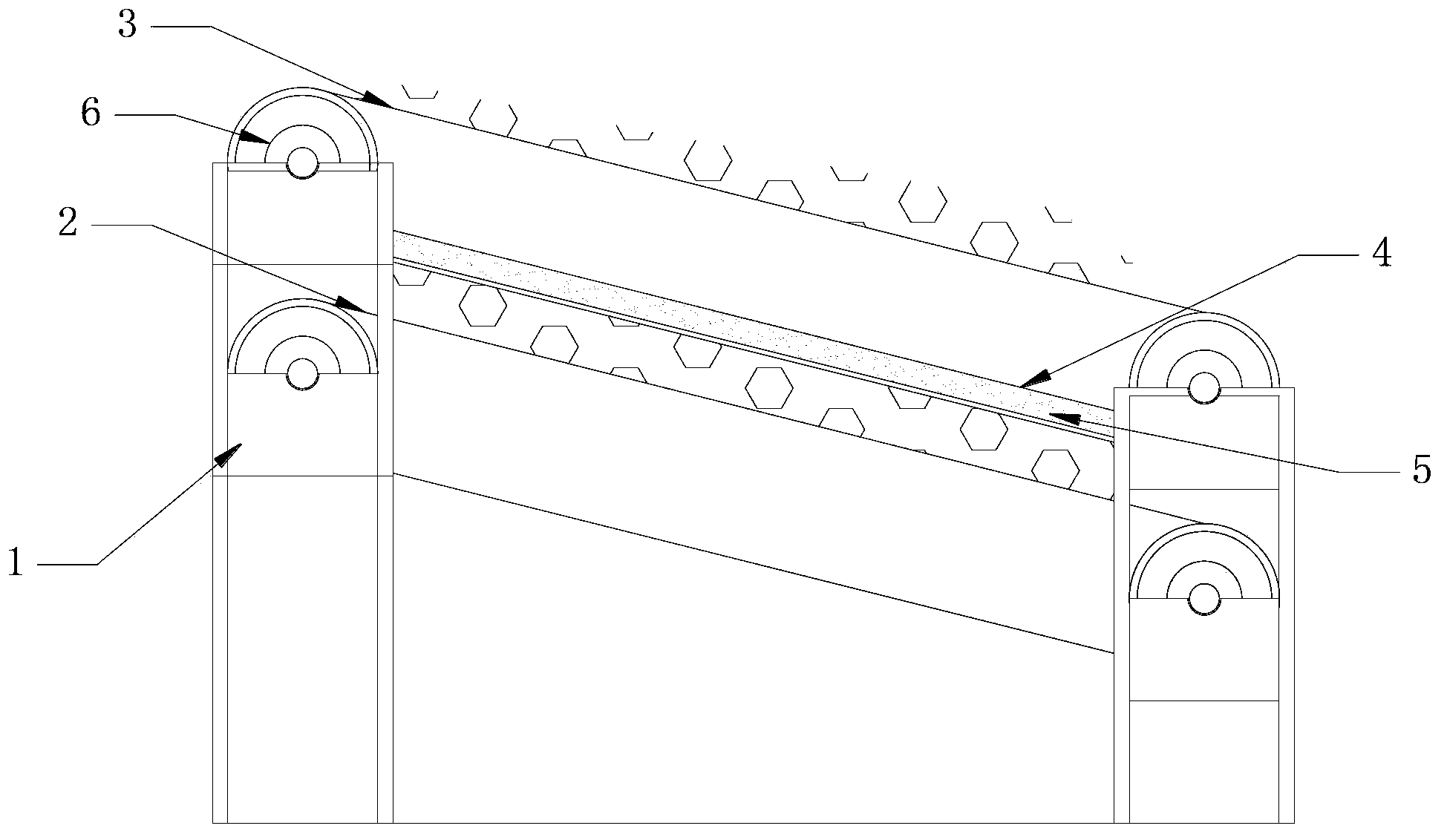

[0011] As shown in Figure 1, a kind of safe deironing conveyer belt, comprises support 1, is located at the conveyer belt 2 on the support 1, the top of described conveyer belt 2 is provided with another iron-absorbing conveyer belt 3, on the iron-absorbing conveyer belt 3 There is a permanent magnet device 4 on one side, and a permanent magnet iron remover 5 is arranged on the permanent magnet device 4 . Use the iron-absorbing conveyor belt to control the position of the permanent magnet iron remover to ensure that the iron in the coal powder can be removed, prevent the coal pulverizer from being damaged, and improve the service life of the coal pulverizer. The iron-absorbing conveyor belt 4 is provided with a permanent magnet iron remover 5 . The permanent magnet iron remover 5 is fixed at the lower end of the iron-absorbing conveyor belt 3 and is distributed to the driving wheel 6 of the conveyor belt. When the permanent magnet iron remover 5 is full of iron, it is transpor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com