A system and method for rapid preparation of ammonia

A preparation system and ammonia water technology, applied in the field of chemical production, can solve the problems of non-recyclability of the configuration process, ineffectiveness of the water seal, complicated process and equipment, etc., to achieve convenient disassembly and scale cleaning, prevention of escape, and simple installation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

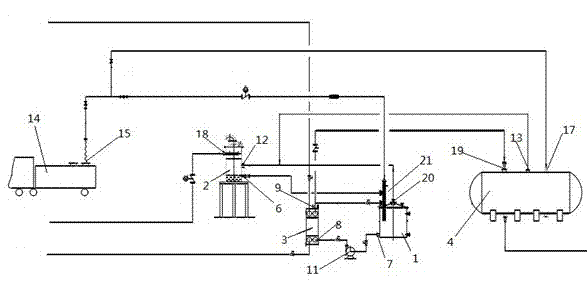

[0039] see figure 1 with figure 2 , the ammonia water rapid preparation system ammonia water preparation tank 1, ammonia absorption tower 2, cooling heat exchanger 3, ammonia water storage tank 4;

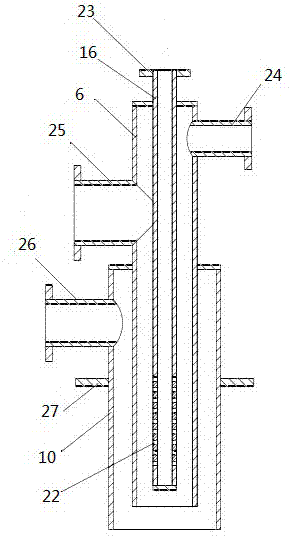

[0040] The ammonia water preparation tank 1 is provided with a diluter 21 extending into the ammonia water preparation tank 1 inside, and the diluter 21 includes a liquid ammonia delivery pipe 16, a new water pipe 6, and a circulating ammonia water pipe 10, and they are arranged on a coaxial center line. The new water pipe 6 and the circulating ammonia water pipe 10 are sequentially socketed outside the liquid ammonia delivery pipe 16, and they are arranged on the coaxial center line; the lower port of the liquid ammonia delivery pipe 16 is closed, and there is a discharge hole 22 at the lower end of the pipe wall; the new water pipe 6 and the lower end of the circulating ammonia water pipe 10 are internally connected with the ammonia water preparation tank 1, and the lower end o...

Embodiment 2

[0047] A method for preparing ammonia based on the preparation system described in Example 1, comprising the steps of:

[0048] (1) Connect the circulating cooling water system to the cooling heat exchanger and turn on the circulating water cooling system;

[0049] (2) Open the new water intake regulating valve and keep the predetermined water supply at 25-30t / h;

[0050] (3) When the liquid level in the ammonia water preparation tank reaches 550-650mm, start the circulation pump;

[0051] (4) Open the liquid ammonia regulating valve, first slowly increase the opening of the liquid ammonia inlet regulating valve within 10% of its total opening, and control the mass percentage concentration of ammonia water in the ammonia water preparation tank to 1-10%; when the liquid ammonia After the ammonia flow rate is stabilized at 3-5t / h, continue to slowly increase the opening of the liquid ammonia feed regulating valve, and control the mass percentage concentration of ammonia water i...

Embodiment 3

[0056] The engineering example that preparation system described in embodiment 1 prepares ammoniacal liquor is as follows:

[0057] Step is as described in embodiment 2, and concrete parameter is:

[0058] Fresh water supply (controlled by fresh water regulating valve, flow meter display value) is 30t / h, liquid ammonia supply (controlled by liquid ammonia regulating valve, inverse value) is 3.28t / h, ammonia water output is 33.28t / h, and the final configuration Ammonia concentration 11% (measured value, mass percentage). The inlet temperature of the ammonia water in the cooling heat exchanger is 33°C, and the outlet temperature of the ammonia water is 27°C (the temperature difference is 6°C). Ammonia water distribution system Ammonia circulation volume ~65m 3 / h, the circulating water volume of the circulating water cooling system is 100m 3 / h. The pressure of the liquid ammonia tanker is 0.5~0.6MPa (gauge pressure), and the pressure of the configured tank reactor is ~0MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com