Halogen-free heat aging-resistant flame-retardant resin compound and wire and cable using the same

A heat-aging-resistant, flame-retardant resin technology, applied in the direction of insulating cables, cables, circuits, etc., can solve the problem of toxic halogen gas emissions and achieve excellent safety effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

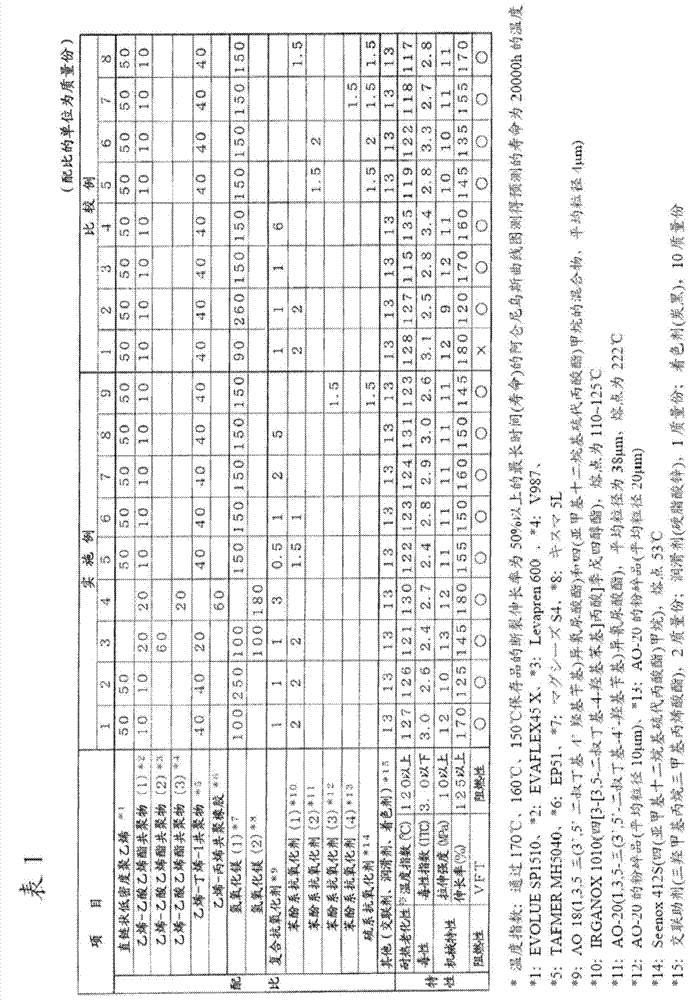

[0048] Hereinafter, examples of the present invention and comparative examples will be described together.

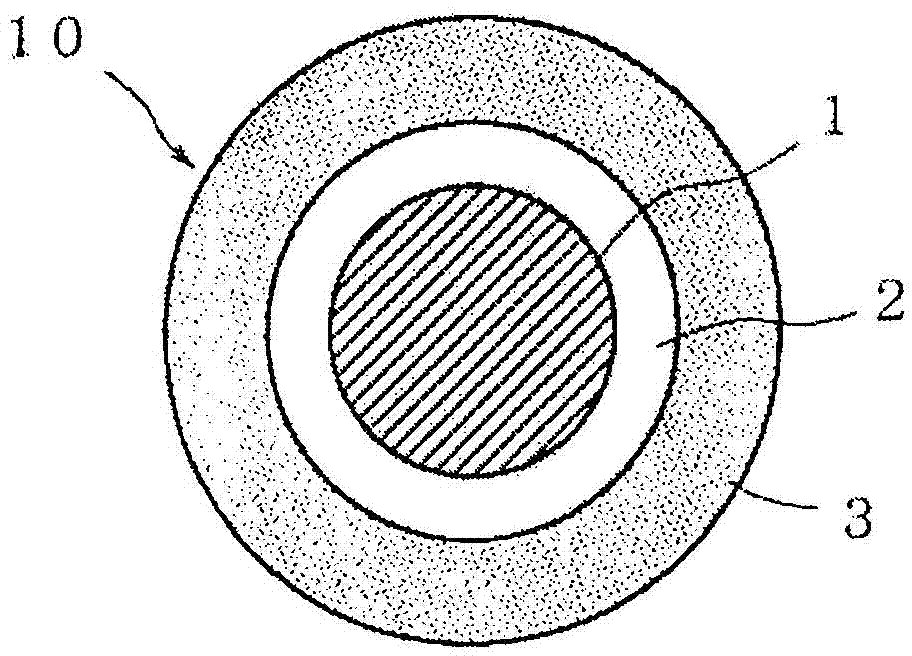

[0049] As described below, prepare figure 1 The cable 10 described in and the non-halogen heat aging resistant flame retardant resin composition as the insulator outer layer 3, the cable 10 is coated with the insulator inner layer 2 on the tinned copper conductor 1, and then extrusion coated Insulator outer layer 3.

[0050] at 0.75mm 2 Twisted tinned copper conductors extruded and coated with 0.8mm insulator inner layer (60 parts by mass of linear low density polyethylene, 30 parts by mass of maleic acid modified α-olefin (co) polymer, 10 parts by mass Part ethylene-ethyl acrylate copolymer, 100 parts by mass of calcined clay, 2 parts by mass of antioxidant, 1 part by mass of trimethylolpropane trimethacrylate, resin composition of 0.5 parts by mass of lubricant) and an insulator of 1.2mm The outer layer is irradiated with 8 Mrad electron beams to perform cross-link...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com