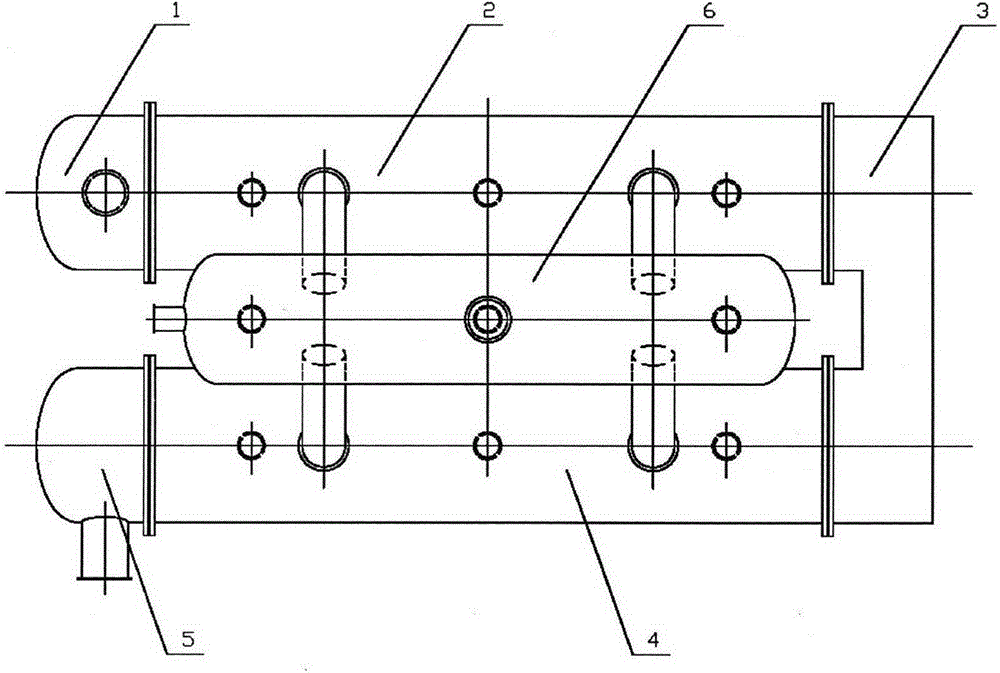

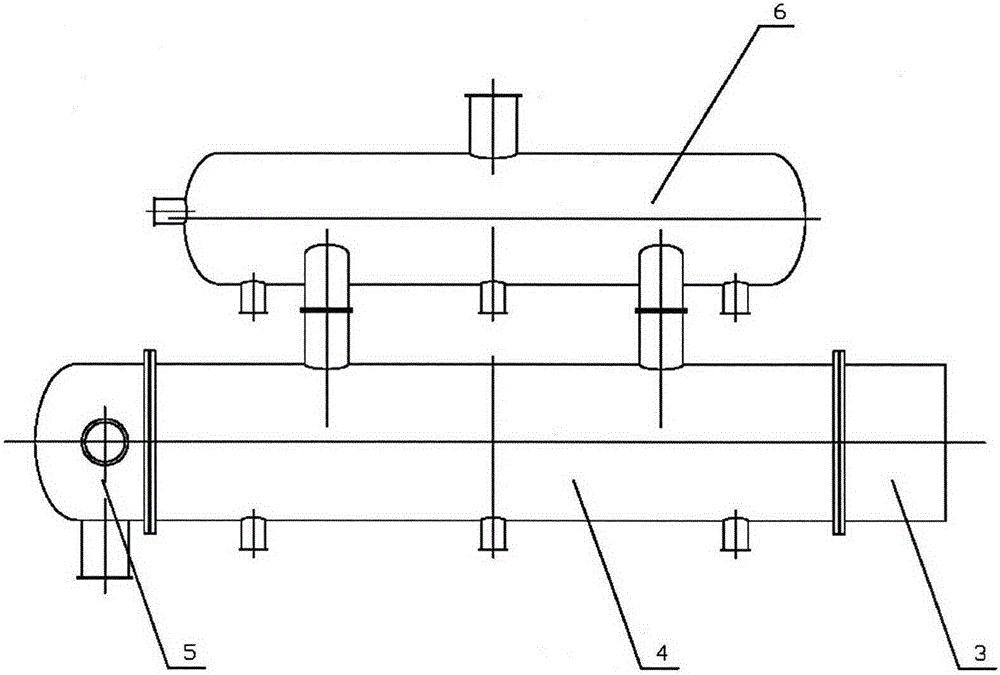

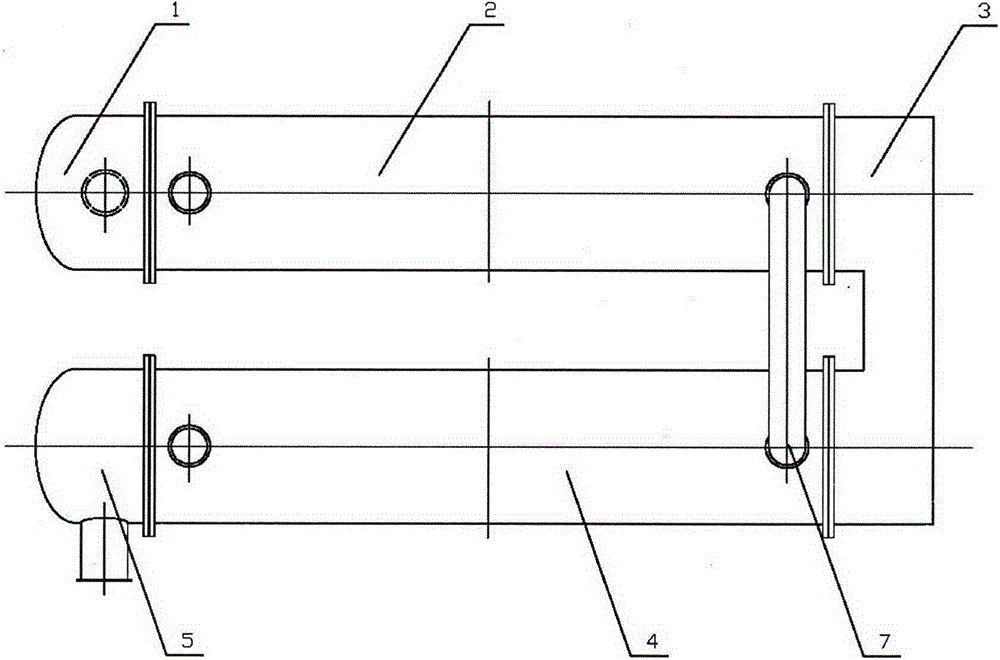

Double symmetrical shell and tube sulfuric acid cooler

A shell-and-tube, double-symmetrical technology is used in the field of heat exchangers for heat recovery in the cooling process of high-temperature concentrated sulfuric acid, which can solve the problems of inability to detect and leak in time for sulfuric acid coolers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The double symmetrical shell-and-tube sulfuric acid cooler used in the circulating acid of the low-temperature potential heat recovery tower of a 300,000-ton / year sulfuric acid plant, including the acid inlet pipe box, heat exchange section A, acid connection pipe box, heat exchange section B, and acid outlet Tube boxes and steam drums. The acid goes through the tube side, and the water goes through the shell side. The acid side of the two heat exchange sections is connected by an acid connection box. The steam riser tubes of heat exchange section A and heat exchange section B are connected to the riser tubes extending into the steam drum and support the steam drum, and the water downpipe of the steam drum is drawn from the bottom of the steam drum to the bottom of the shell side of the two heat exchange sections. Water outlet connection. The shell side of the heat exchange section is the process of water evaporation and vaporization. The double symmetrical shell-and-t...

Embodiment 2

[0055] The dual-symmetric shell-and-tube sulfuric acid cooler used in the low-temperature potential heat recovery tower of the 800,000-ton / year sulfuric acid plant, which includes the acid inlet pipe box, heat exchange section A, acid connection pipe box, heat exchange section B, Acid outlet pipe box, connecting water pipe. Connect the acid sides of the two heat exchange sections with the acid connection box, and connect the water sides of the two heat exchange sections with the connecting water pipe. The water goes through the shell side, the acid goes through the tube side, and the full countercurrent heat exchange is used to heat the boiler feed water. The series acid cooler is also called the boiler feed water heater. The string acid concentration is 99.60%, the acid inlet temperature is 180°C, and the outlet temperature is 150°C, heating the boiler feed water from 104°C to 172°C. In stable operation, the acid temperature at the outlet of heat exchange section A (inlet te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com