Preparation method for high pure aluminium metallographic sample

A metallographic sample and high-purity technology, which is applied in the field of preparing metallographic samples showing the structure of high-purity aluminum, can solve the problems of incomplete metallographic display grain boundaries, affecting the normal appearance of grain boundaries, and inability to distinguish grain boundaries, etc. Simple operation, reduced chance of scratches, low labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A method for preparing a high-purity aluminum metallographic sample, comprising the steps of:

[0017] (1) Sampling: Sampling 14mmX16mm high-purity aluminum samples with a thickness of 12mm by wire cutting. It is required to have a smooth metallographic surface without obvious unevenness;

[0018] (2) Coarse grinding: on the polishing machine, at 200 # Polish the silicon carbide water abrasive paper with water, and when the polished surface looks smooth and even, change to 400 # The silicon carbide water abrasive paper is polished with water. After changing the sand, the sample should be rotated 90 degrees until the scratches of the previous process are completely worn away, and the direction of the new scratches is the same;

[0019] (3) fine grinding: will use 400 # Sandpaper ground samples, after switching the angle of 90 degrees, respectively at 600 # , 800 # and 1000 # Carry out hand grinding on sandpaper. The hand grinding force should be moderate. If the for...

Embodiment 2

[0024] A method for preparing a high-purity aluminum metallographic sample, comprising the steps of:

[0025] (1) Sampling: Sampling 12mmX10mm high-purity aluminum samples with a thickness of 13mm by wire cutting. It is required to have a smooth metallographic surface without obvious unevenness;

[0026] (2) Coarse grinding: On the polishing machine, the sample is roughly ground to 400 # sandpaper;

[0027] (3) Fine grinding: at 600 in turn # , 800 # and 1000 # Grind the sample block with water on the sandpaper;

[0028] (4) Polishing: according to step (4) of Example 1, the sample was electropolished on an electropolishing instrument for 55 seconds at room temperature;

[0029] (5) Film coating: according to the step (5) of Example 1, the film coating was also carried out on the polishing machine for 2 minutes and 40 seconds.

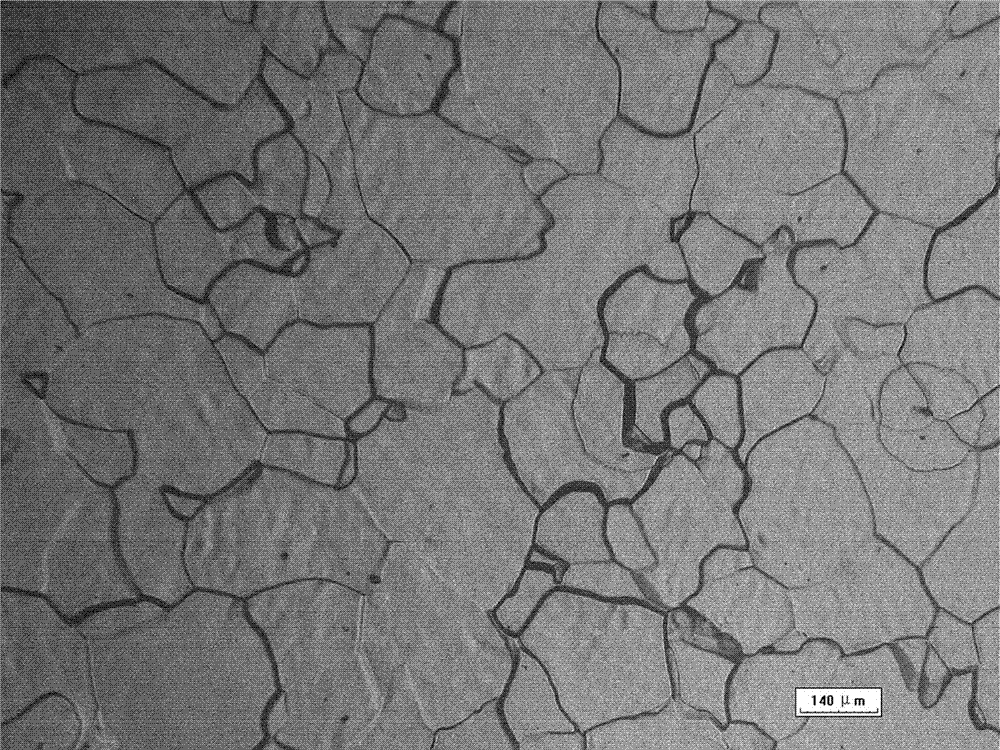

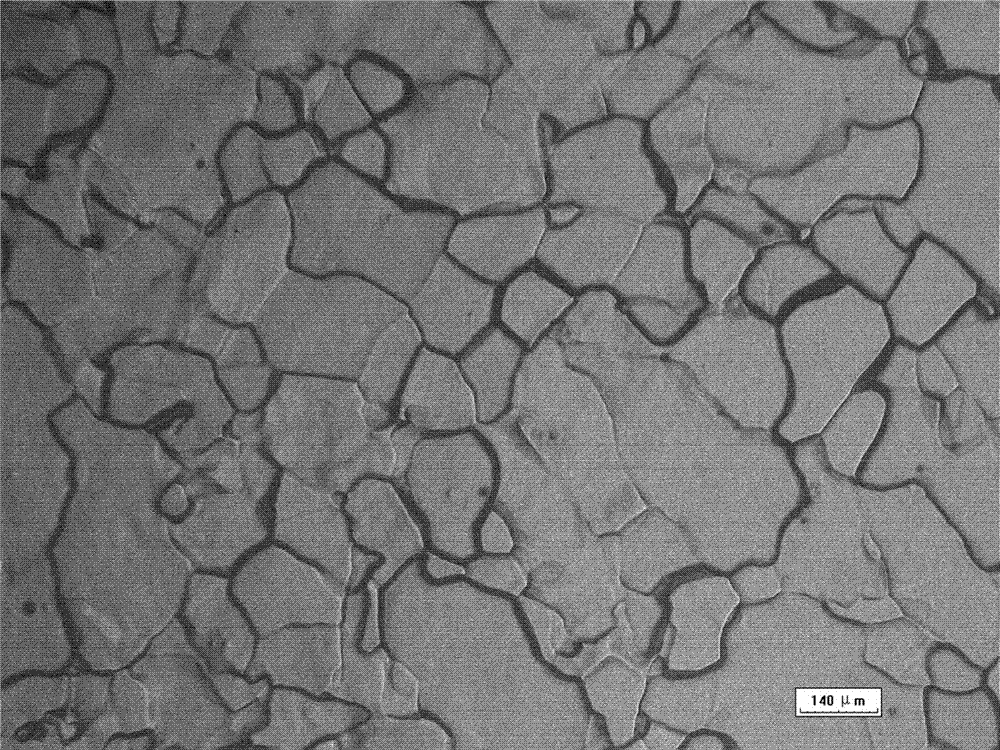

[0030] This example is the metallographic photograph of 99.9999% high-purity aluminum prepared by the technology of the present invention, from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com