Metallic film capacitor

A metallized film and capacitor technology, which is applied in the field of capacitors, can solve the problems that the metal electrodes cannot be guaranteed to fit tightly, there is a lot of residual air, and the air cannot be completely excluded.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

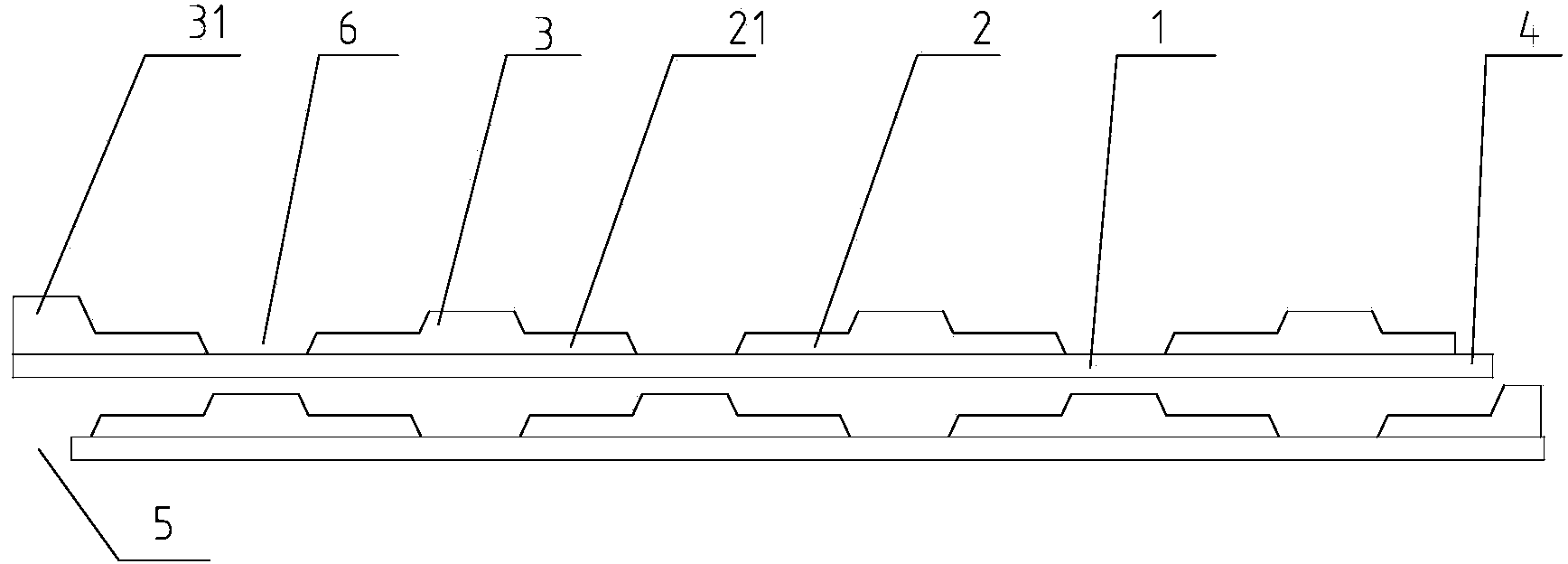

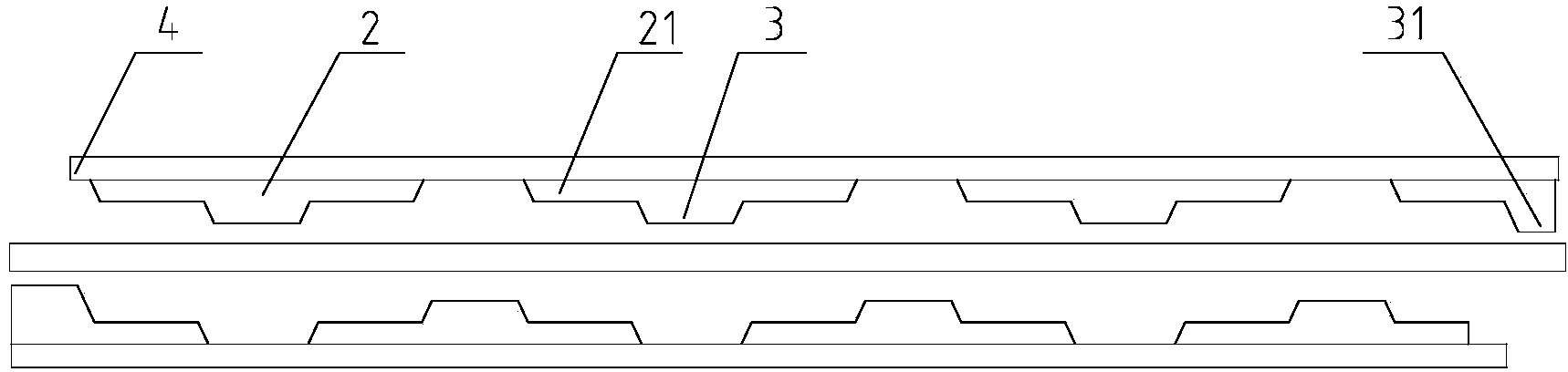

[0021] The invention provides a metallized film capacitor, comprising at least two layers of metallized films, the metallized film includes a thin film dielectric layer and metal electrodes spaced apart on the thin film dielectric layer, intermediate margins are arranged between adjacent metal electrodes, metal The electrode includes a substrate and a thickened part arranged on the substrate. The thickened part of two adjacent layers of metallized film corresponds to the middle margin on the other layer of metallized film. After the metallized film is wound and pressed, the thickened part Embedded in the middle margin, the thickened portion fits tightly between the adjacent substrates. Compared with the prior art, it is not easy to bond between the spaced metal electrodes after the metallized film is flattened. In the present invention, a thickened part is arranged on the metal electrode. After the metallized film is wound and flattened, the thickened part can be pressed into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com