Structure and manufacturing method of power device MPT-TI-IGBT

A technology of -MPT-TI-IGBT and power device, which is applied to the structure and preparation field of power device-MPT-TI-IGBT, and can solve the problems of large on-state loss, very poor, and high saturation voltage drop V.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

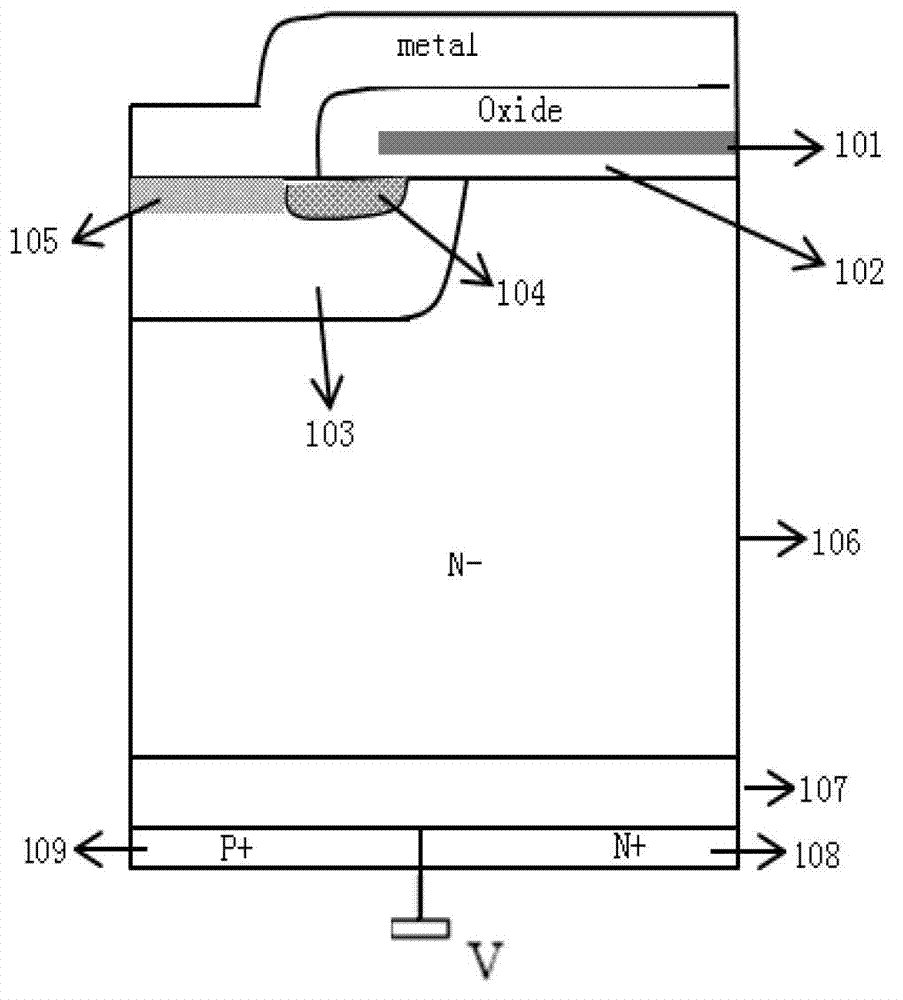

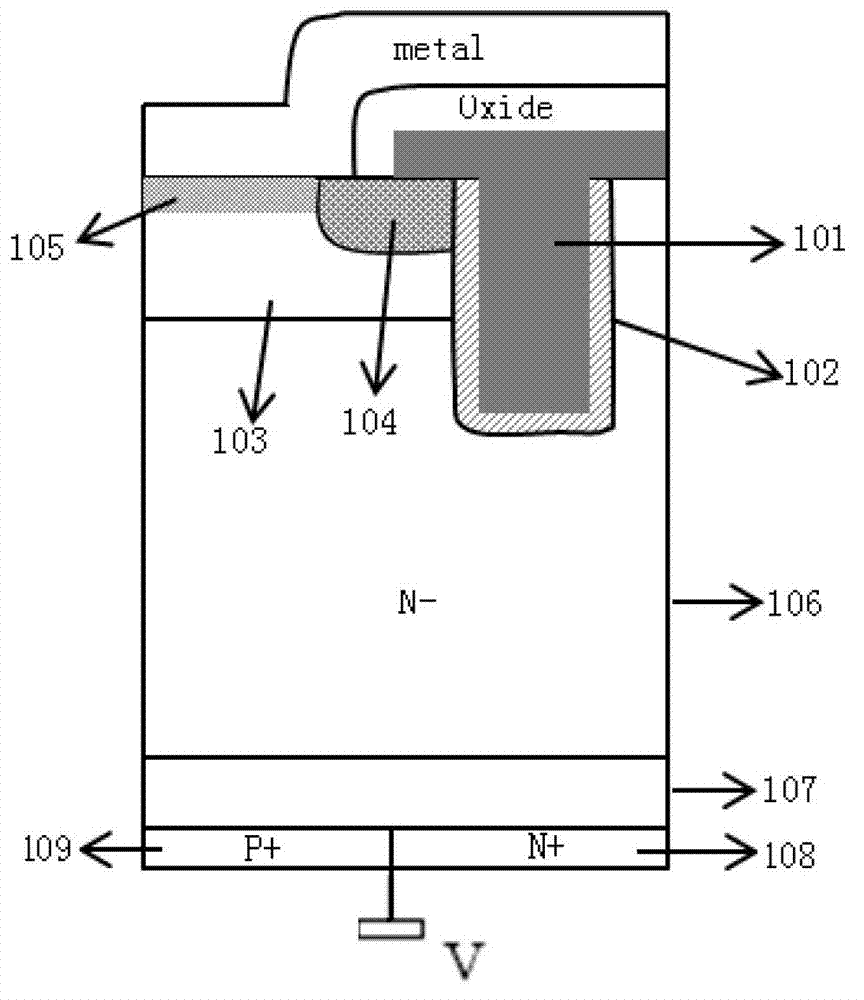

Embodiment 1

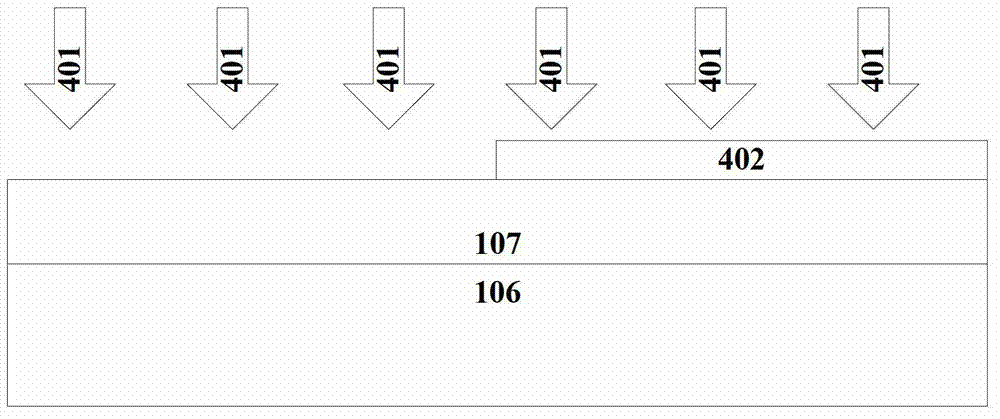

[0030] After the front side process is completed, the silicon wafer is thinned from the back side, and a micro-through layer 107 is formed under the drift region 106;

[0031] see image 3 , using a mask to define the shape of the photoresist 402 and injecting N-type doping (or P-type doping) 401;

[0032] see Figure 4 , forming a short circuit region 108 (or collector region 109 ) of the first (or second) conductivity type after degelling and annealing;

[0033] see Figure 5 , using a mask to define the shape of the photoresist 404 and injecting P-type doping (or N-type doping) 403;

[0034] see Figure 6 , forming the collector region 109 (or short circuit region 108 ) of the second (or first) conductivity type after degelling and annealing;

[0035] see Figure 7 , and finally the back side is metallized to form the collector metal 301 .

Embodiment 2

[0037] After the front side process is completed, the silicon wafer is thinned from the back side, and a micro-through layer 107 is formed under the drift region 106;

[0038] see Figure 8 , implanting N-type doping (or P-type doping) 401 on the back of the entire silicon wafer;

[0039] see Figure 9 , forming a short circuit region 108 (or collector region 109 ) of the first (or second) conductivity type on the entire silicon wafer after annealing;

[0040] see Figure 10 , use a mask to define photoresist and etch away part of the short-circuit region 108 (or collector region 109) of the first (or second) conductivity type implanted with impurities 404, leaving only the first (or second) conductivity type short-circuit region 108 (or collector region 109 ) in a part of the silicon wafer ii) short circuit area 108 (or collector area 109 ) of conductive type;

[0041] see Figure 11 , implanting P-type doping (or N-type doping) 403 and then annealing to form the collect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com