Direct alcohol fuel cell membrane electrode, and preparation and applications thereof

A fuel cell and membrane electrode technology, which is applied to fuel cells, battery electrodes, solid electrolyte fuel cells, etc., can solve the problems of poor stability, complicated preparation process, and high resistance of alcohol-resistant membrane membrane, and achieves low cost and simple and easy preparation method. The effect of mature production method and production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

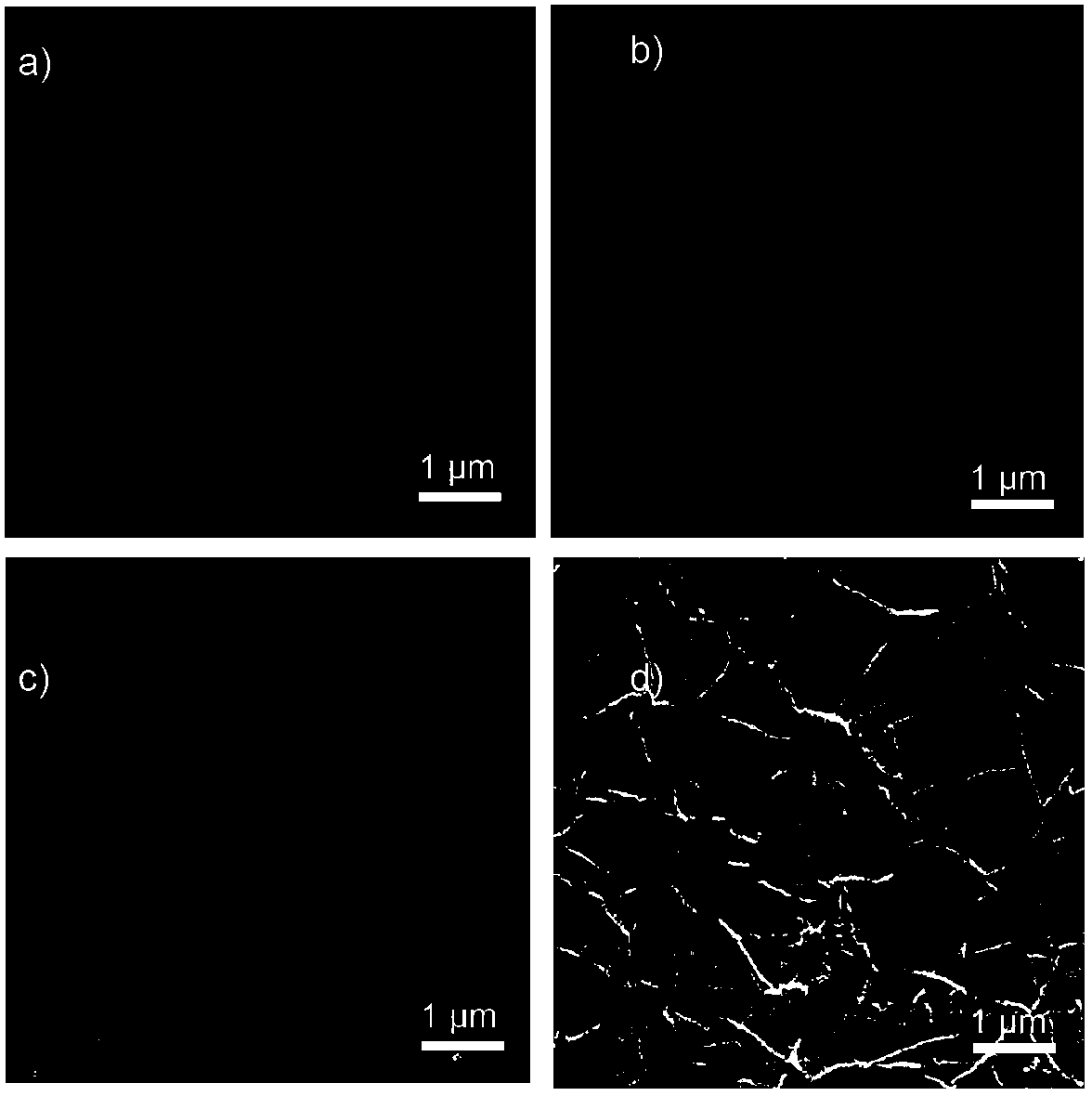

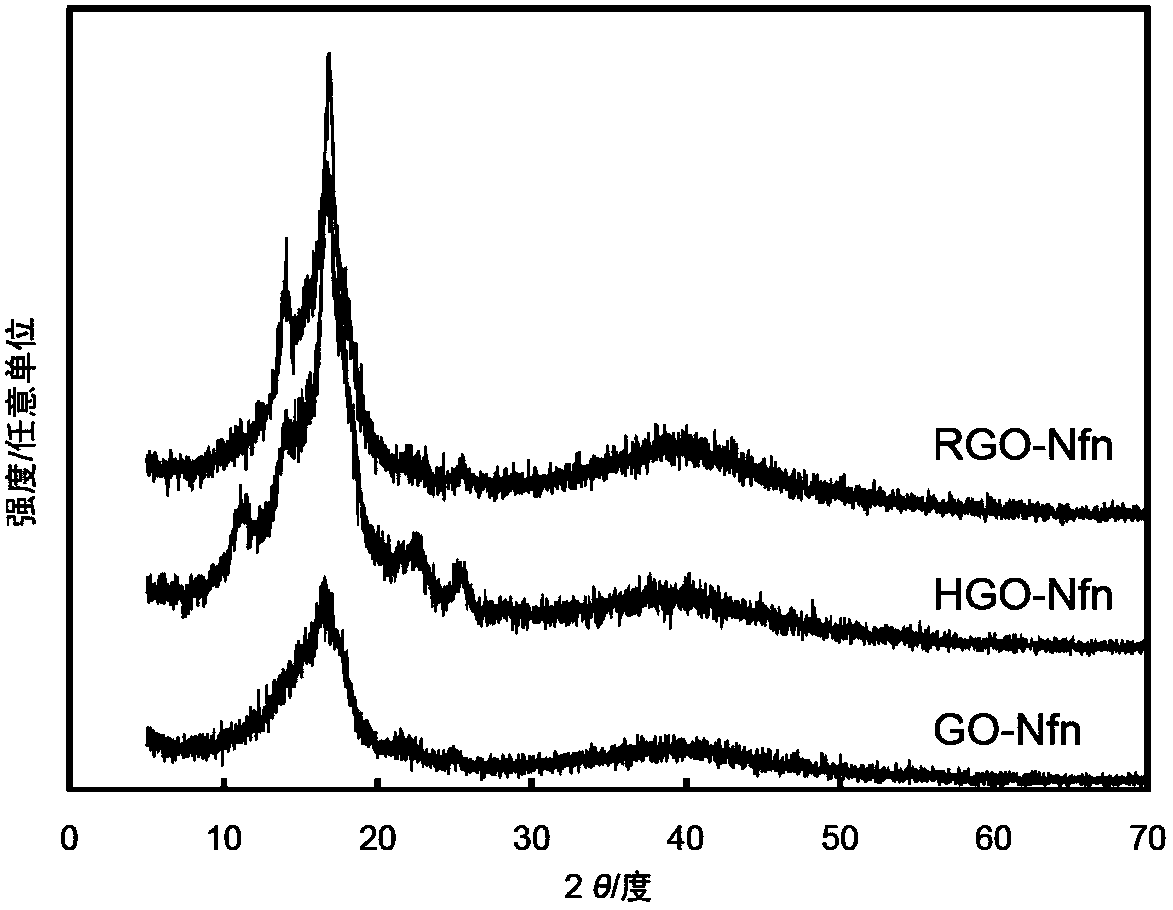

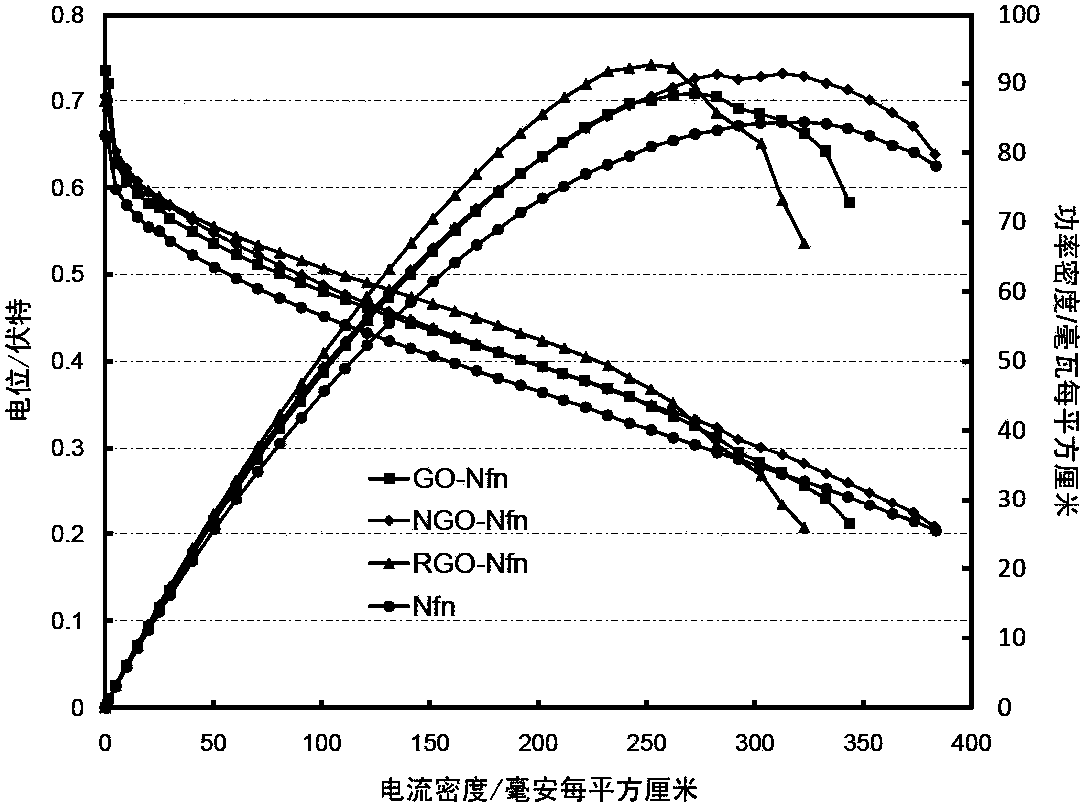

[0035] This embodiment is a membrane electrode prepared by adding a graphene oxide layer between the anode side of the Nafion membrane and the anode catalyst layer on the basis of the traditional membrane electrode.

[0036] Preparation of anode diffusion layer: Commercial Toray carbon paper impregnated with 15% PTFE, commercial Vulcan XC-72 carbon powder mixed with 10% Nafion was loaded on carbon paper by scraping method, and the load was 1 mg cm -2 .

[0037] Preparation of cathode with GDE structure: commercial Toray carbon paper impregnated with 15% PTFE, commercial VulcanXC-72 carbon powder mixed with 10% PTFE was loaded on carbon paper by scraping method, and the load was 1 mg cm -2 ; Commodity JM 60% Pt / C catalyst mixed with 10% Nafion was loaded on the diffusion layer by knife coating method, and the load was 2 mg cm -2 .

[0038] The preparation of the anode catalyst layer of CCM structure specifically comprises the following steps:

[0039] 1) Preparation of graph...

Embodiment 2

[0045] The preparation of the anode catalyst layer of the CCM structure described in this example is based on Example 1, spraying Nafion emulsion on the surface of the graphene oxide layer.

[0046] Preparation of anode diffusion layer: same as Example 1;

[0047] The preparation of the negative electrode of GDE structure: with embodiment 1;

[0048] The preparation of the anode catalyst layer of CCM structure comprises the following steps:

[0049] 1) Preparation of graphene oxide slurry: same as Example 1;

[0050] 2) Preparation of graphene oxide layer: spray Nafion solution with a mass concentration of 5% on the surface of the Nafion115-graphene oxide layer prepared in step 2) of the above-mentioned embodiment 1, so that the Nafion load is 0.01 mg / cm 2 , to get Nafion115-graphene oxide layer-Nafion layer, marked as (NGO-Nfn sample).

[0051] 3) Preparation of anode catalyst layer with CCM structure: same as Example 1;

[0052] 4) Preparation of membrane electrodes and ...

Embodiment 3

[0054] The preparation of the anode catalytic layer of the CCM structure described in the present embodiment is on the basis of embodiment 2, to the Nafion115-graphene oxide layer-Nafion layer that makes NaBH 4 Prepared by dipping in aqueous solution.

[0055] Preparation of anode diffusion layer: same as Example 1;

[0056] The preparation of the negative electrode of GDE structure: with embodiment 1;

[0057] The preparation of the anode catalyst layer of CCM structure comprises the following steps:

[0058] 1) Preparation of graphene oxide slurry: same as Example 1;

[0059] 2) Preparation of graphene oxide layer: For the Nafion115-graphene oxide layer-Nafion layer prepared in step 2) of the above-mentioned embodiment 2, in 0.5mg mL -1 Concentration of NaBH 4 Immersion treatment was carried out for 0.5h in , marked as (RGO-Nfn sample);

[0060] 3) Preparation of anode catalyst layer with CCM structure: same as Example 1;

[0061] 4) Preparation of membrane electrodes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com