Stone pattern flowerpot, manufacturing method and vertical and horizontal embossing machine for manufacturing stone pattern flowerpot

A technology of vertical and horizontal engraving machines, applied in botany equipment and methods, engraving, decorative art, etc., can solve the constraints of the finished product rate and mass production of flower pots with three-dimensional prominent patterns, high cost of plastic flower pot molds, and high cost of flower pots. The product cannot be released from the mold, etc., to achieve the effect of improving the value of art appreciation, rich hand feeling, and outstanding three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

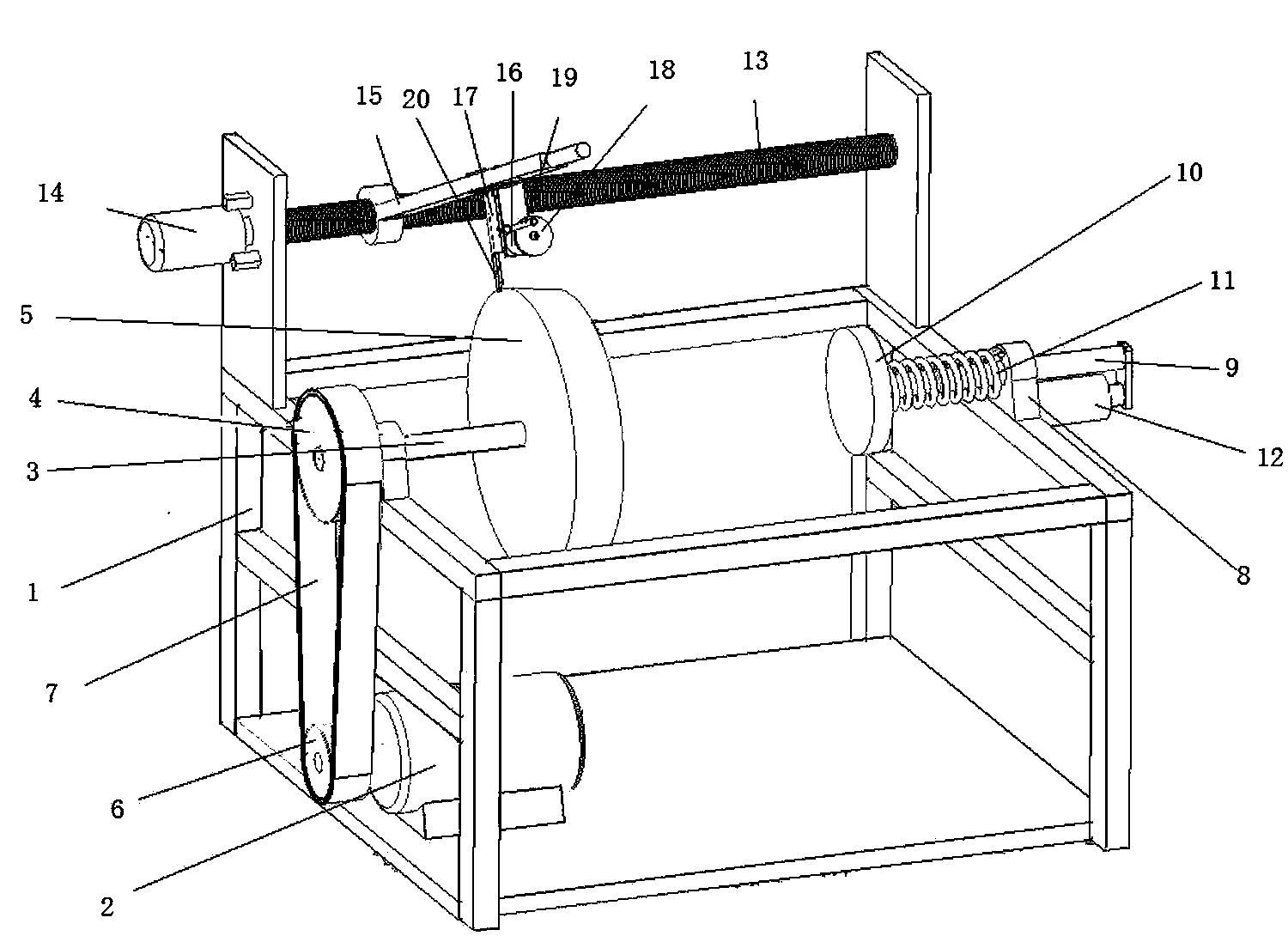

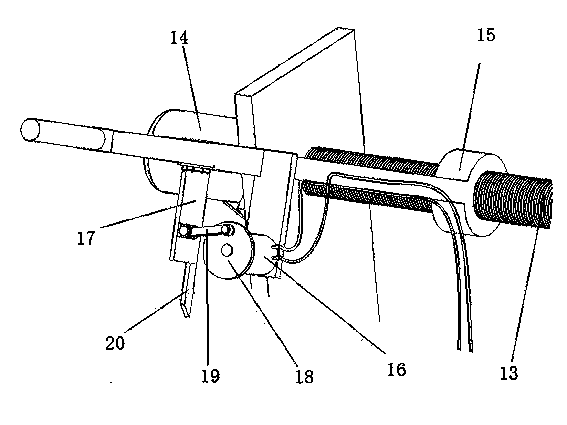

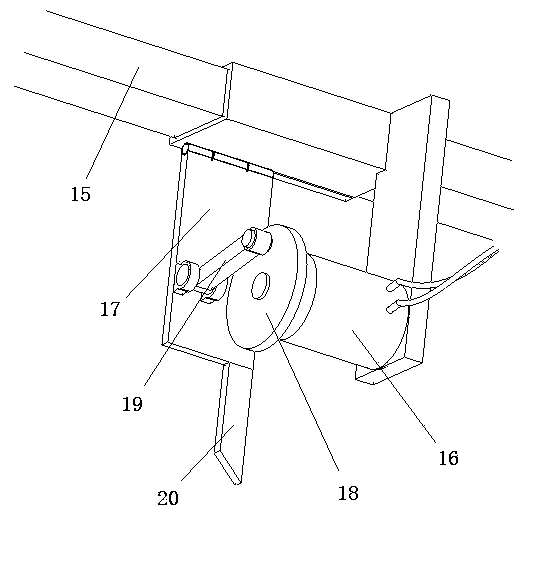

[0042] Embodiment 1: as figure 1 and figure 2As shown, a vertical and horizontal engraving machine includes a frame 1. The frame 1 is rectangular and welded by square pipes. The upper and lower parts of the frame 1 are provided with a driving motor 2, and the left side of the upper surface of the frame 1 is provided with a bearing seat. A bearing is arranged in the bearing seat, and a main rotary shaft 3 is arranged in the bearing, and the middle part of the main rotary shaft 3 is installed in the bearing. The two ends of the main rotary shaft 3 are respectively installed with a large pulley 4 and a fixed plate 5 located above the frame 1. The motor shaft of the drive motor 2 is provided with a small pulley 6, which is connected by a belt 7 between the small pulley 6 and the large pulley 4, and a support 8 is arranged on the right side of the upper surface of the frame 1, and a circular hole is arranged on the support 8. A secondary rotary shaft 9 is arranged in the circular...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that the transmission mechanism between the drive motor and the main rotary shaft in Embodiment 1 is changed to a large gear and a pinion, the pinion is arranged on the motor shaft of the drive motor, and the large gear is arranged on the On the main rotary shaft, the large gear meshes with the small gear, and the drive motor drives the main rotary shaft to rotate through the gear pair. Other technical solutions in this embodiment are the same as those in Embodiment 1.

[0046] The transmission precision of the gear transmission mechanism is higher than that of the belt transmission mechanism. After the gear transmission is adopted, the engraved patterns are more exquisite.

Embodiment 3

[0048] The difference between this embodiment and embodiment 1 is that on the basis of the technical solution of embodiment 1, a taper is provided on the edge of the fixed plate, and an anti-slip material is provided on the outer surface of the fixed plate, and the anti-slip material is rubber or canvas.

[0049] The edge of the fixed plate is designed with a taper. After the outer surface of the fixed plate is coated with anti-slip material, when the inner wall of the flowerpot contacts the fixed plate, the fixed plate can better clamp the main flower pot.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com