Carbon nanosphere and preparation method and application thereof

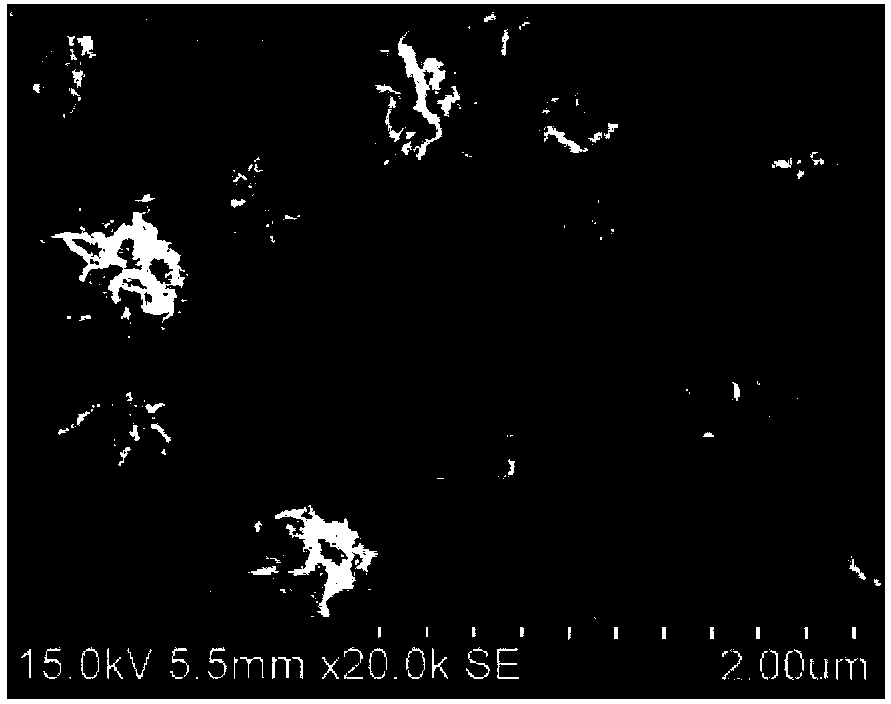

A carbon nanosphere and carbon nanoparticle technology, applied in the fields of nanocarbon, nanotechnology, nanotechnology, etc., can solve the problems such as the research reports of hedgehog-shaped carbon nanospheres that have not been found, the inability to effectively control the particle size, and the limited surface area of carbon particles. , to achieve the effect of rich surface, uniform particle size and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

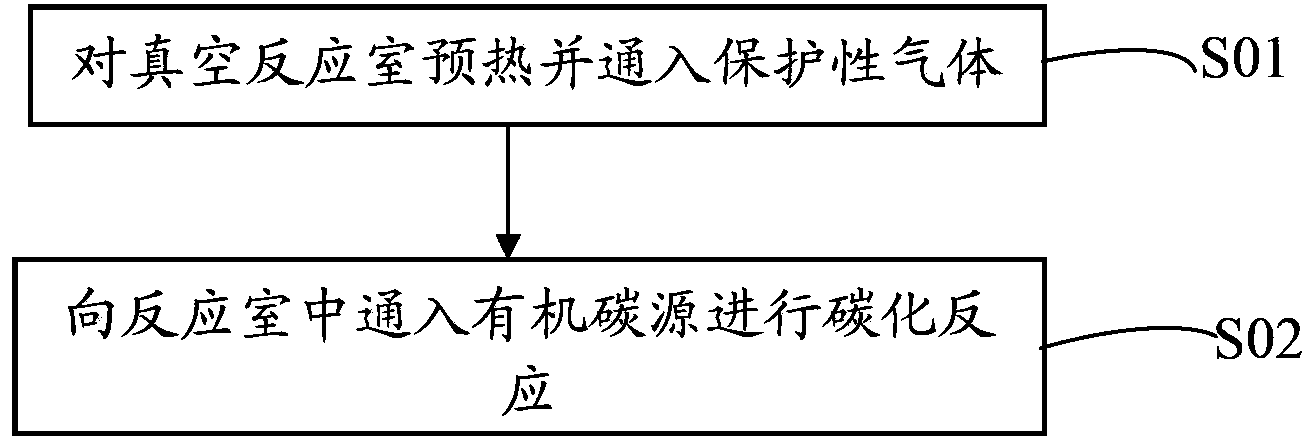

[0024] Correspondingly, the embodiment of the present invention also provides a method for preparing the above-mentioned carbon nanospheres. For the process flow of the method for preparing carbon nanospheres, please refer to figure 2 . The carbon nanosphere preparation method comprises the following steps:

[0025] Step S01. Preheating the vacuum reaction chamber and introducing protective gas:

[0026] After preheating the vacuum reaction chamber in which the carbonization catalyst is placed, a protective gas is introduced from the bottom of the reaction chamber; wherein, the flow rate of the protective gas ensures that the catalyst is suspended;

[0027] Step S02. Introducing an organic carbon source into the reaction chamber for carbonization reaction:

[0028] Keep feeding protective gas into the reaction chamber and continue to heat the reaction chamber to 800-1300°C, then feed organic carbon source gas into the reaction chamber for carbonization reaction for 10-120 m...

Embodiment 1

[0041]A carbon nanosphere and a preparation method thereof, the preparation method of the carbon nanosphere comprises the steps of:

[0042] (1) Soak 0.1g of iron powder in ethanol and acetone respectively, put it in an ultrasonic cleaner for 30 minutes, then filter and transfer to a vacuum drying oven to dry at 80°C for 3 hours;

[0043] (2) Take out the iron powder and put it into a reaction chamber with a volume of 10L and a reaction table diameter of 25cm, and seal the reaction chamber. Use a mechanical pump, a Roots pump and a molecular pump to pump the reaction chamber to 1Pa step by step, and keep it for 30 minutes. , turn off the molecular pump and start heating;

[0044] (3) When the temperature of the reaction chamber reaches 500°C, the protective gas nitrogen is introduced from the bottom of the reaction chamber, and the gas flow rate is continuously increased. Observe from the observation mirror until the iron powder is suspended in the reaction chamber, and the ai...

Embodiment 2

[0049] A carbon nanosphere and a preparation method thereof, the preparation method of the carbon nanosphere comprises the steps of:

[0050] (1) Soak 0.15g of copper powder in ethanol and acetone, respectively, and place it in an ultrasonic cleaner for 30 minutes, then filter and transfer to a vacuum drying oven to dry at 100°C for 2 hours;

[0051] (2) Take out the copper powder and put it in the reaction chamber, and seal the reaction chamber. Use mechanical pump, Roots pump and molecular pump to pump the reaction chamber to 0.001Pa step by step, and keep it for 1 minute, then turn off the molecular pump and start heating;

[0052] (3) When the temperature of the reaction chamber reaches 500°C, the protective gas hydrogen is introduced from the bottom of the reaction chamber, and the gas flow rate is continuously increased. Observe from the observation mirror until the copper powder is suspended in the reaction chamber, and the air flow is no longer increased;

[0053] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com