Waterproof flame-retardant protective jacket layer used for cable and manufacturing process of protective jacket layer

A technology of flame-retardant sheath and manufacturing process, which is applied in the field of flame-retardant sheath layer and its preparation process, and can solve the problems of unqualified thermal deformation, rising cost, difficulty in meeting the requirements of product index performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

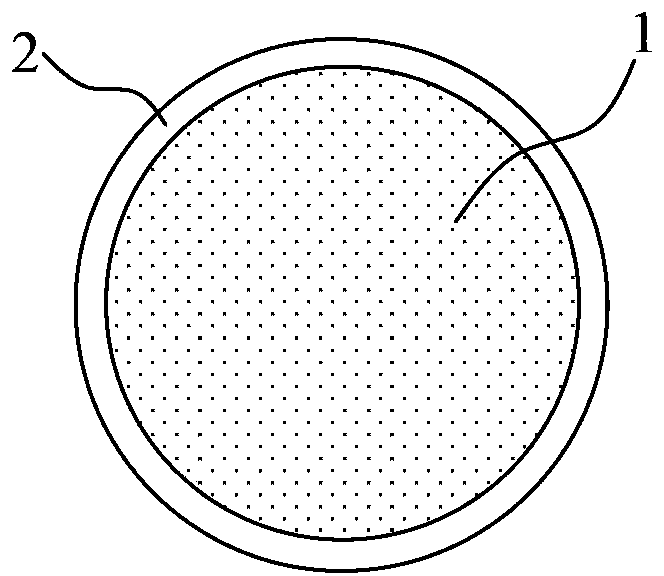

[0041] Embodiment 1: A water-resistant and flame-retardant sheath layer used on a cable, the cable includes a cable core 1 and a water-resistant and flame-resistant sheath layer 2 coated on the outer surface of the cable core 1, the water-resistant and flame-retardant sheath Layer 2 consists of the following components by weight, as shown in Table 1:

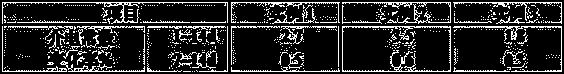

[0042] Table 1

[0043] Example 1 Example 2 Example 3 100 parts of polyvinyl chloride 100 100 100 Trioctyl trimellitate 20~30 parts 29 25 20 15~25 parts of isodecyl phthalate 25 20 15 Environmental calcium zinc composite stabilizer 5~10 parts 9 8 6 Composite rare earth stabilizer 5~10 parts 10 5 7 4~8 parts of antimony trioxide 4 8 6 Lubricant 0.3~1 part 0.5 0.9 0.3 Antioxidant 0.1~0.5 parts 0.1 0.3 0.5 Nano barium sulfate 3.5~7 parts 3.8 6.5 5.2 2.6~5.2 parts of calcined kaolin 2.8 4 5 Nano silicon dioxide 3.5~7 parts 5 6.8 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com