Conductive composite material and its preparation method

A technology of conductive composite materials and polymer materials, applied in the direction of conductive materials dispersed in non-conductive inorganic materials, etc., can solve the problems of complicated operation steps, inapplicability to large-scale industrial production, and large cost, and achieve simple operation steps, The effect of saving preparation cost and reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

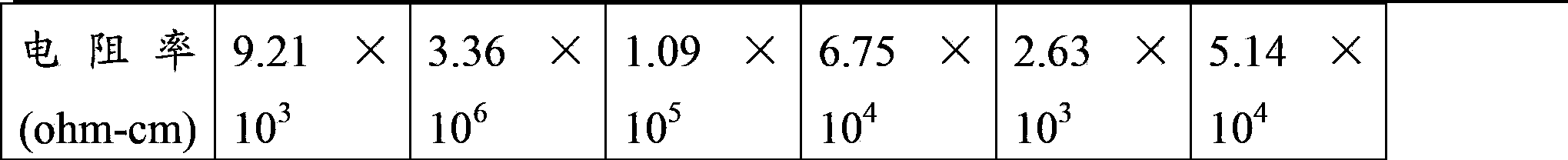

Embodiment 1

[0025] Take the raw material according to the following parts by weight:

[0026] 92 parts of PBT,

[0027] 2 parts graphene,

[0028] 6 parts of carbon nanotubes,

[0029] Accurately weighed materials are sent into the twin-screw extruder through a precision metering feeding device, and the materials are fully fused under the shearing, mixing and conveying of the screws, and finally extruded and granulated through the die head; the twin-screw extruder The length-to-diameter ratio of the extruder is 20:1, the temperature of each section is controlled at 235°C-255°C, and the speed is 20rpm; the carbon nanotube / graphene / PBT pellets are accurately weighed and added to the hot-pressing mold, and then the mold is placed Put it into a flat vulcanizer for hot pressing molding, preheat for 5 minutes, hot pressing temperature 245 ° C, hot pressing time 5 minutes, hot pressing force 5 MPa, then water circulation cooling for 20 minutes, out of the mold to obtain carbon nanotube / graphen...

Embodiment 2

[0031] Take the raw material according to the following parts by weight:

[0032] 99 parts of PBT,

[0033] 0.1 part of graphene,

[0034] 0.9 parts of carbon nanotubes,

[0035] Accurately weighed materials are sent into the twin-screw extruder through a precision metering feeding device, and the materials are fully fused under the shearing, mixing and conveying of the screws, and finally extruded and granulated through the die head; the twin-screw extruder The length-to-diameter ratio of the extruder is 25:1, the temperature of each section is controlled at 235°C-255°C, and the speed is 25rpm; the carbon nanotube / graphene / PBT pellets are accurately weighed and added to the hot-pressing mold, and then the mold is placed Put it into a flat vulcanizer for hot pressing molding, preheat for 5 minutes, hot pressing temperature 245 ° C, hot pressing time 5 minutes, hot pressing force 5 MPa, then water circulation cooling for 20 minutes, out of the mold to obtain carbon nanotube / g...

Embodiment 3

[0037] Take the raw material according to the following parts by weight:

[0038] 94 parts of PBT,

[0039] 0.5 parts of graphene,

[0040] 5.5 parts of carbon nanotubes,

[0041] Accurately weighed materials are sent into the twin-screw extruder through a precision metering feeding device, and the materials are fully fused under the shearing, mixing and conveying of the screws, and finally extruded and granulated through the die head; the twin-screw extruder The length-to-diameter ratio of the extruder is 23:1, the temperature of each section is controlled at 235°C-255°C, and the speed is 25rpm; the carbon nanotube / graphene / PBT pellets are accurately weighed and added to the hot-pressing mold, and then the mold is placed Put it into a flat vulcanizer for hot pressing molding, preheat for 5 minutes, hot pressing temperature 245 ° C, hot pressing time 5 minutes, hot pressing force 5 MPa, then water circulation cooling for 20 minutes, out of the mold to obtain carbon nanotube / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com