Adhesive tape for plastic lens molding and molding method of plastic lens molded product

A technology for plastic lenses and adhesive tapes, applied in applications, adhesives, household appliances, etc., can solve the problems of increased cross-linking density, slow reaction speed, and changes, and achieve the effect of suppressing gaps and less changes in cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

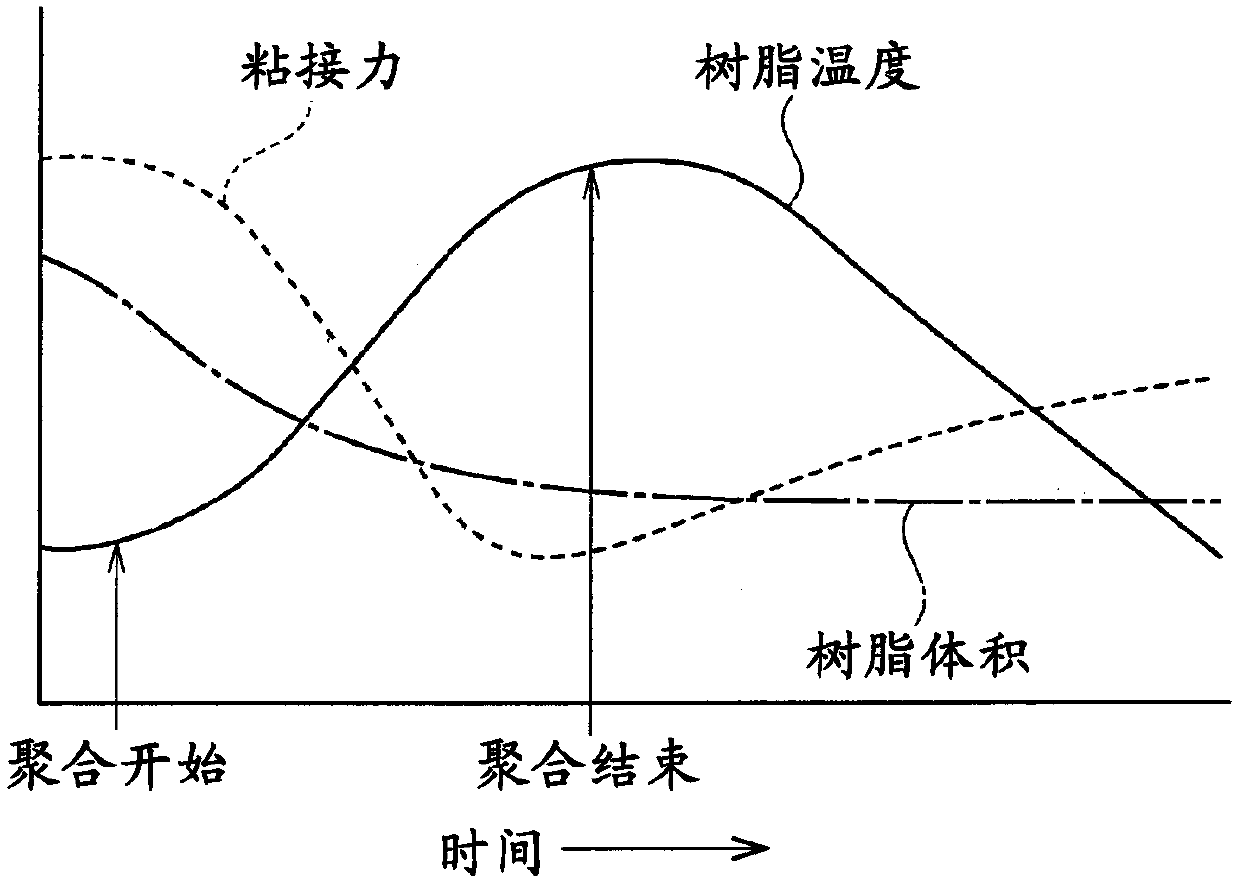

Problems solved by technology

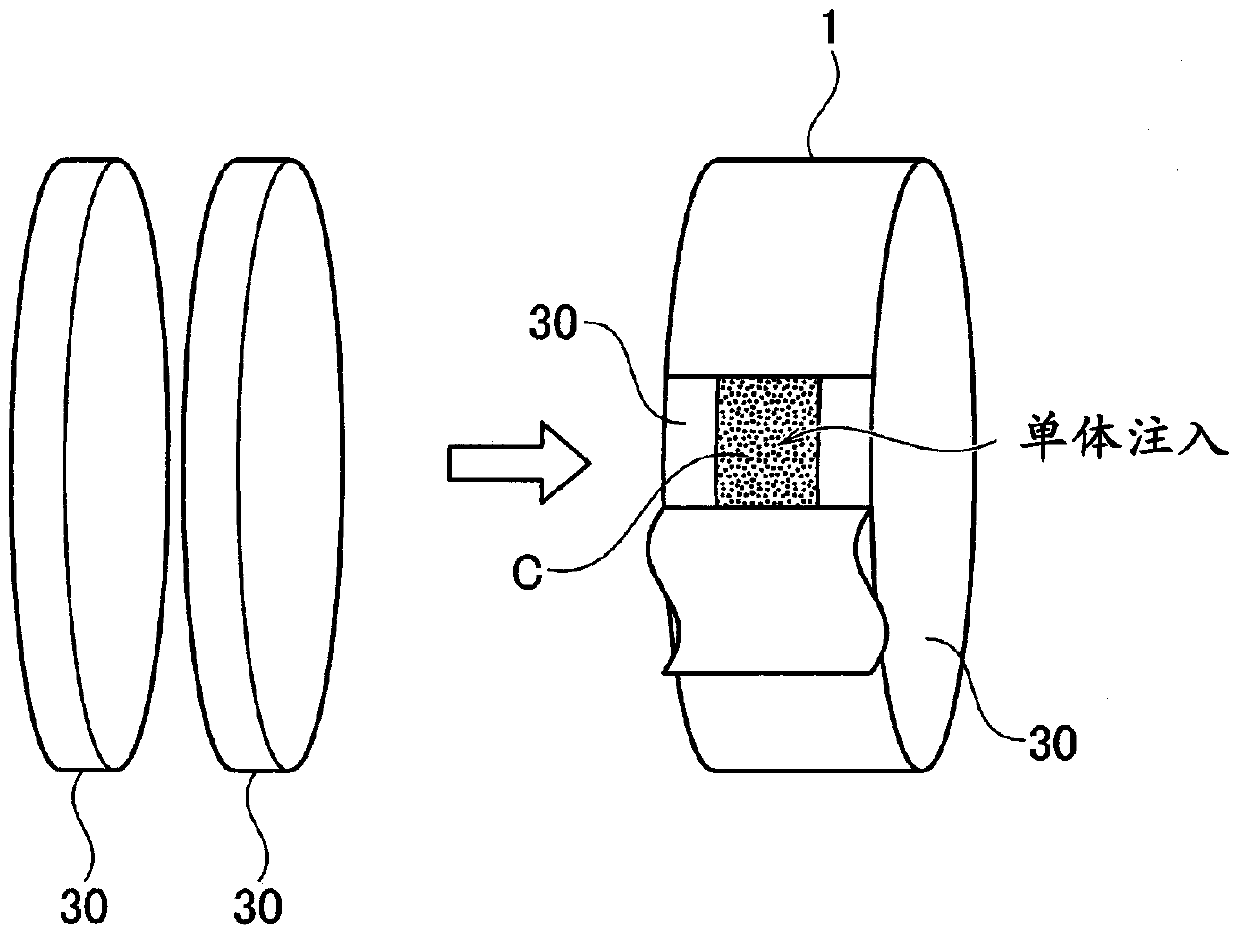

Method used

Image

Examples

Embodiment 1

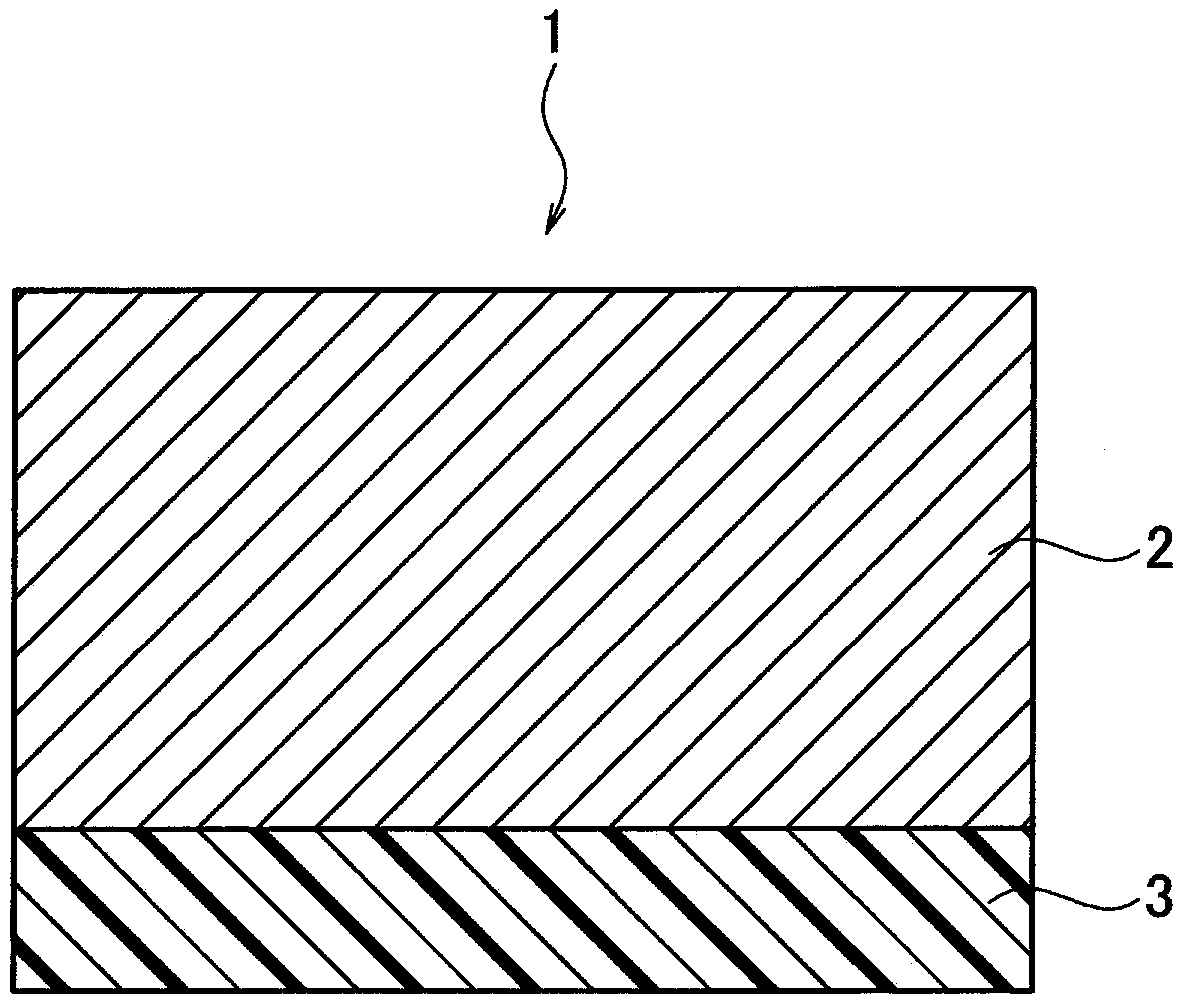

[0124] Prepare a toluene solution formulated to contain 60 parts by weight of Adhesive A, 15 parts by weight of Adhesive C, and 25 parts by weight of Adhesive D, and mix a crosslinking agent (BY24 manufactured by Toray Dow Corning Co., Ltd.) -741) 0.60 parts by weight (1.0 parts by weight relative to the alkenyl-containing adhesive), catalyst (NC-25 manufactured by Toray Dow Corning Co., Ltd.) 0.50 parts by weight are uniformly stirred and mixed in toluene, and added to the above toluene solution And stirring, the adhesive agent solution was produced. This adhesive solution was applied on a polyester (PET) film substrate (thickness 50 μm) manufactured by Toray Co., Ltd. so that the thickness of the adhesive layer was 20 μm, and the heat treatment (drying) was performed at a maximum temperature of 180° C. , curing to obtain an adhesive tape for plastic lens molding with a total thickness of 70 μm (also referred to as adhesive tape sometimes below).

[0125] As shown in Table 1...

Embodiment 2

[0134] Prepare a toluene solution formulated to contain 60 parts by weight of Adhesive A, 15 parts by weight of Adhesive C, and 25 parts by weight of Adhesive D, and mix a crosslinking agent (BY24 manufactured by Toray Dow Corning Co., Ltd.) -741) 0.3 parts by weight (0.5 parts by weight relative to the alkenyl-containing adhesive), catalyst (NC-25 manufactured by Toray Dow Corning Co., Ltd.) 0.50 parts by weight are uniformly stirred and mixed in toluene, and added to the above toluene solution And stirring, the adhesive agent solution was produced. Using this adhesive solution, an adhesive tape was produced in the same manner as in Example 1.

[0135] Adhesive tape 1 using this adhesive, as shown in Table 2, has an adhesive force to a glass plate of 5.0 N / 10 mm, a holding force of 132 minutes at 70°C, and a low molecular weight silicone of 3 to 10 polymers. The total amount of alkanes was 120 μg / g, and the total amount of 3- to 20-mer low-molecular-weight siloxanes was 3521...

Embodiment 3

[0139] Prepare a toluene solution formulated to contain 60 parts by weight of Adhesive A, 15 parts by weight of Adhesive C, and 25 parts by weight of Adhesive D, and mix a crosslinking agent (BY24 manufactured by Toray Dow Corning Co., Ltd.) -741) 0.9 parts by weight (1.5 parts by weight relative to the alkenyl-containing adhesive), catalyst (NC-25 manufactured by Toray Dow Corning Co., Ltd.) 0.50 parts by weight are uniformly stirred and mixed in toluene, and added to the above toluene solution And stirring, the adhesive agent solution was produced. Using this adhesive solution, an adhesive tape was produced in the same manner as in Example 1.

[0140] Adhesive tape 1 using this adhesive, as shown in Table 2, has an adhesive force of 4.0 N / 10 mm to a glass plate, a retention force of 247 minutes at 70°C, and low-molecular-weight silicone of 3 to 10 polymers. The total amount of alkanes was 55 μg / g, and the total amount of 3- to 20-mer low-molecular-weight siloxanes was 2722 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com