Post-forging heat treatment method for large forgings of hot wall hydrogenation reactor

A hydrogenation reactor and post-forging heat treatment technology, which is applied in the field of heat treatment, can solve the problems of high manufacturing cost and long production cycle, and achieve the effects of reducing production cycle and cost, increasing water quenching and tempering, and preventing white spots

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

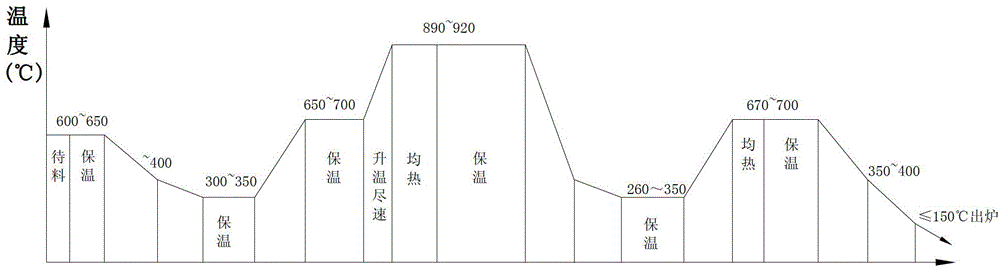

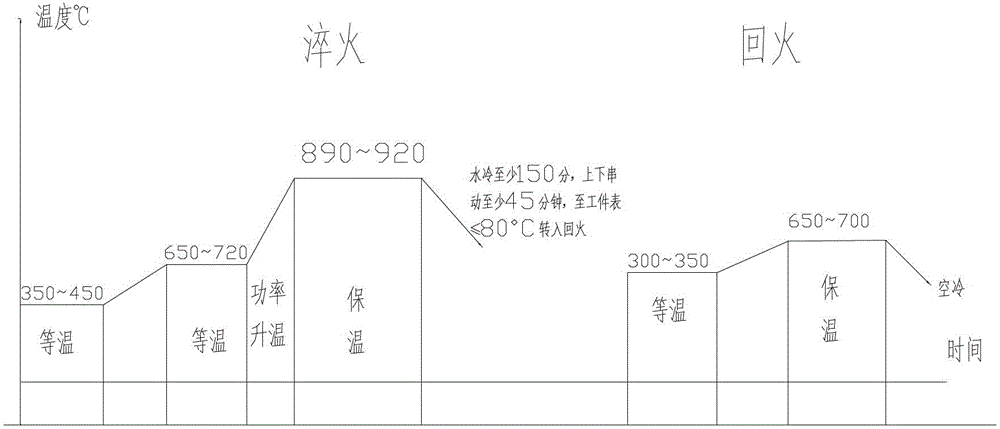

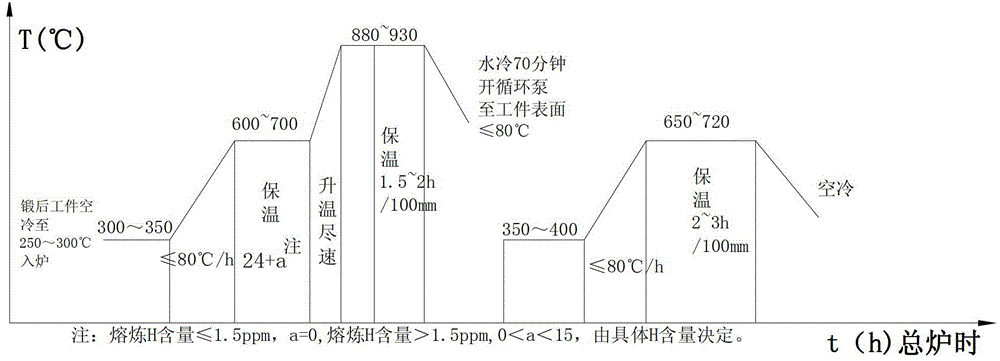

[0024] Such as image 3 As shown, the post-forging heat treatment method of the large forging of the hot wall hydrogenation reactor of the present invention is used for after forging the forging of the hot wall hydrogenation reactor whose material is 12Cr2Mo1, the outer diameter is 1500-4500 mm, and the wall thickness is 100-300 mm. Heat treatment, including the following steps:

[0025] The first step is to control the final forging temperature to 850-950°C. After forging, clean the surface cracks, folds and other macroscopic defects of the forging, and then air-cool until the surface temperature of the forging is 250-350°C, preferably 300-350°C; The forging is sent into the heating furnace, and the temperature of the heating furnace chamber is 300-450°C, preferably 300-350°C;

[0026] The purpose of this step is to use the residual heat of forging to implement a normalizing to obtain the effect of refining grains.

[0027] In the second step, the temperature of the heating...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com