Apparatus and method for manufacturing electronic component

A technology for electronic components and manufacturing devices, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, manufacturing tools, etc., can solve the problems of curling, complex cutting knife structure, unsatisfactory blade, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

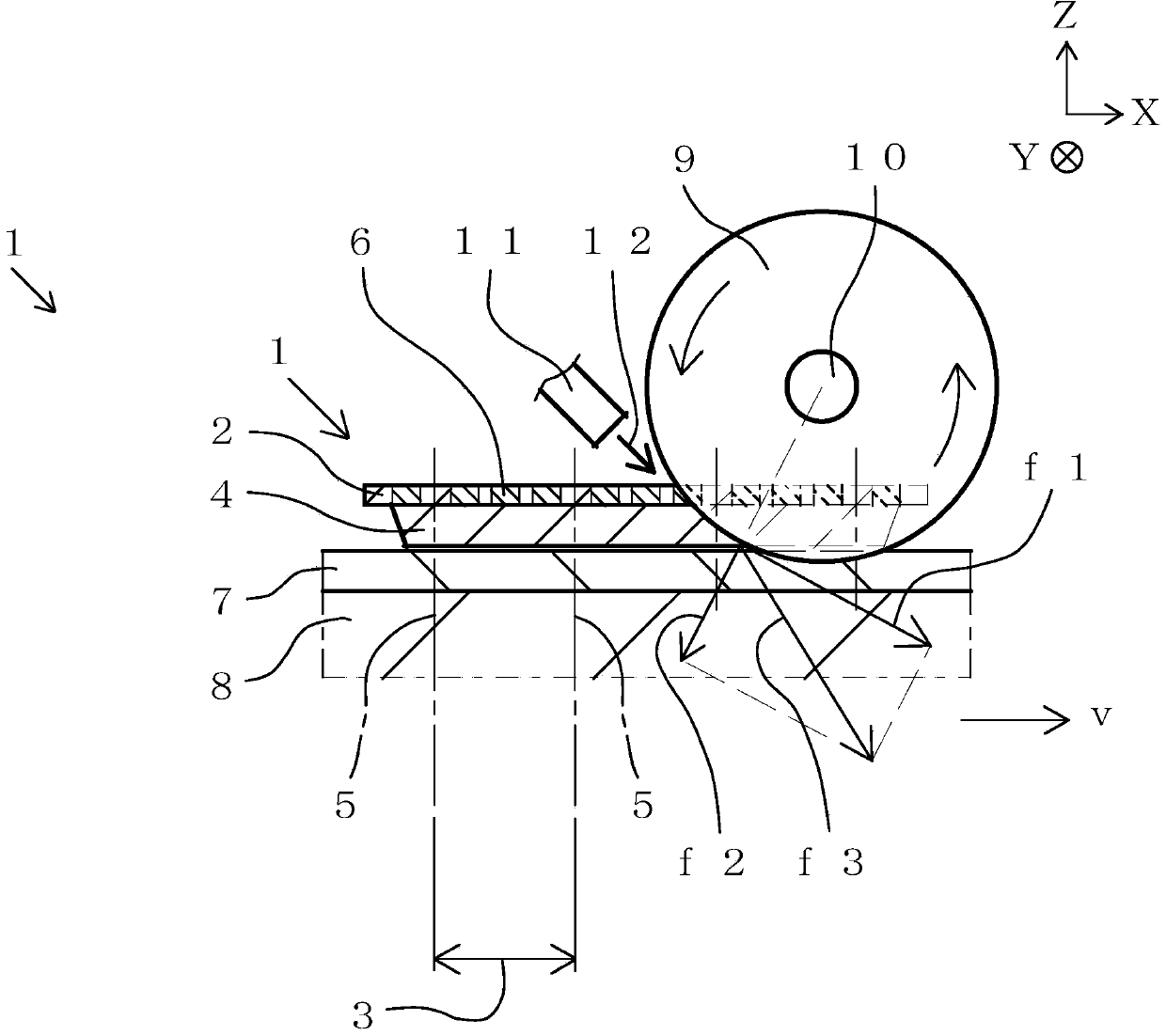

[0072] refer to figure 2 , the method of manufacturing an electronic component according to Embodiment 1 of the present invention, and more specifically, the method of cutting an electronic component will be described. According to the present embodiment, the resin package 1 having a double-layer structure as an object to be cut is cut in two steps. The control part CTL is a control mechanism which controls at least the rotation direction and rotation speed of the rotary knife 9, and the relative movement direction and movement speed of the table 8 and the rotation shaft 10 (spindle). The resin package 1 has: a substrate 2 having a plurality of regions 3; chip-like elements mounted on the plurality of regions 3; The lowermost layer of the resin package 1 is set as the uppermost layer. Furthermore, a rotational axis 10 is provided on the mandrel. The mandrel is omitted from the illustration. In addition, the chip-shaped element is not exposed on the surface of the resin pa...

Embodiment 2

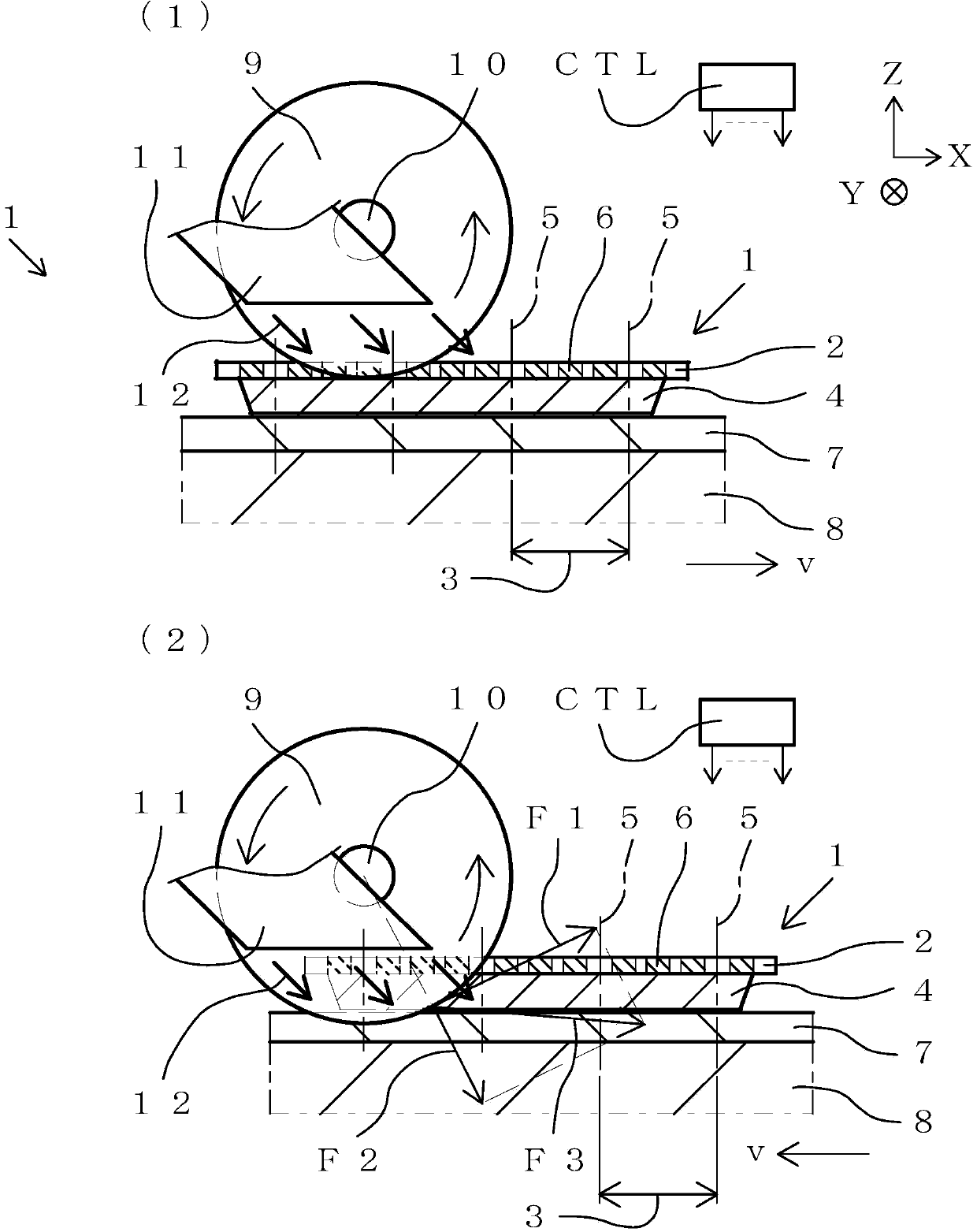

[0087] refer to image 3 , the cutting method for electronic component manufacturing according to Embodiment 2 of the present invention will be described. According to the present embodiment, the resin package 1 having a double-layer structure as an object to be cut is cut in two steps. The difference between the present embodiment and the first embodiment is that the posture in which the resin package 1 is fixed on the upper surface of the table 8 is reversed in the Z direction. In addition, in the present embodiment, the structure of the nozzle 11 and the ejection of the cutting fluid 12 using the nozzle 11 are implemented as in the first embodiment. For this reason, in the following description, the description related to the ejection of the cutting fluid 12 using the nozzle 11 will be omitted.

[0088] Such as image 3 As shown in (1), in this embodiment, the entire thickness of the encapsulating resin 4 (uppermost layer in this embodiment) in the resin package 1 is cut a...

Embodiment 3

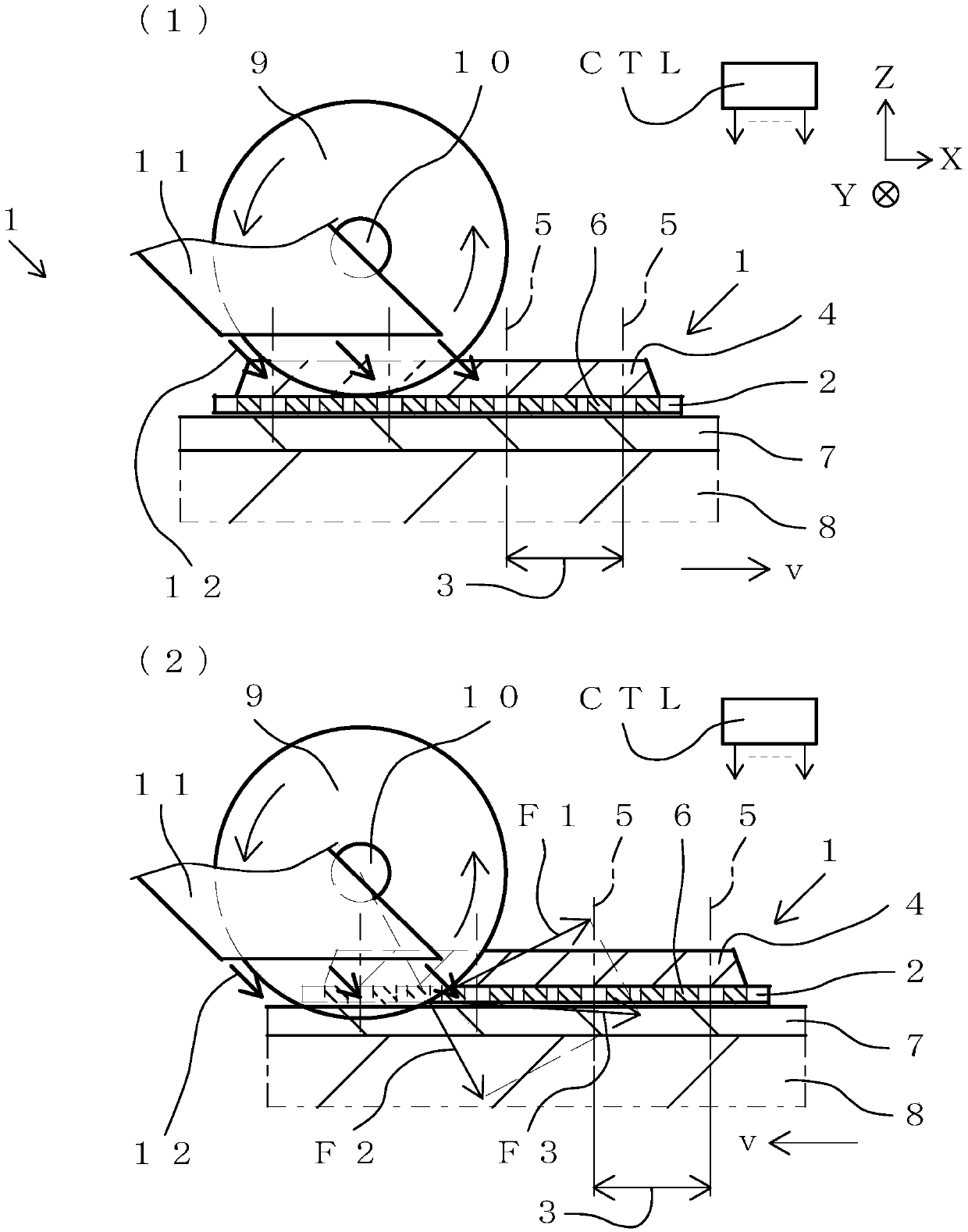

[0103] refer to Figure 4 , the cutting method for electronic component manufacturing according to Embodiment 3 of the present invention will be described. In this embodiment, the resin package 13 which is the object to be cut is cut in three steps. The difference between this embodiment and Embodiment 1 is that the resin package 13 has a three-layer structure. Such as Figure 4 As shown, the resin package 13 has a substrate 2 (the lowermost layer in this embodiment), a reflection member 14 (the middle layer in this embodiment) and encapsulating resin 4 (the uppermost layer in this embodiment) A three-layer structure is formed.

[0104] Such as Figure 4 As shown, a concave portion 15 is formed in the reflection member 14 . The concave portion 15 is provided on each of the plurality of regions 5 provided on the substrate 2 . In each recess 15, the upper surface of the substrate 2 is exposed. Die bonding pads 16 and wire bonding pads 17 are formed on the exposed upper su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com