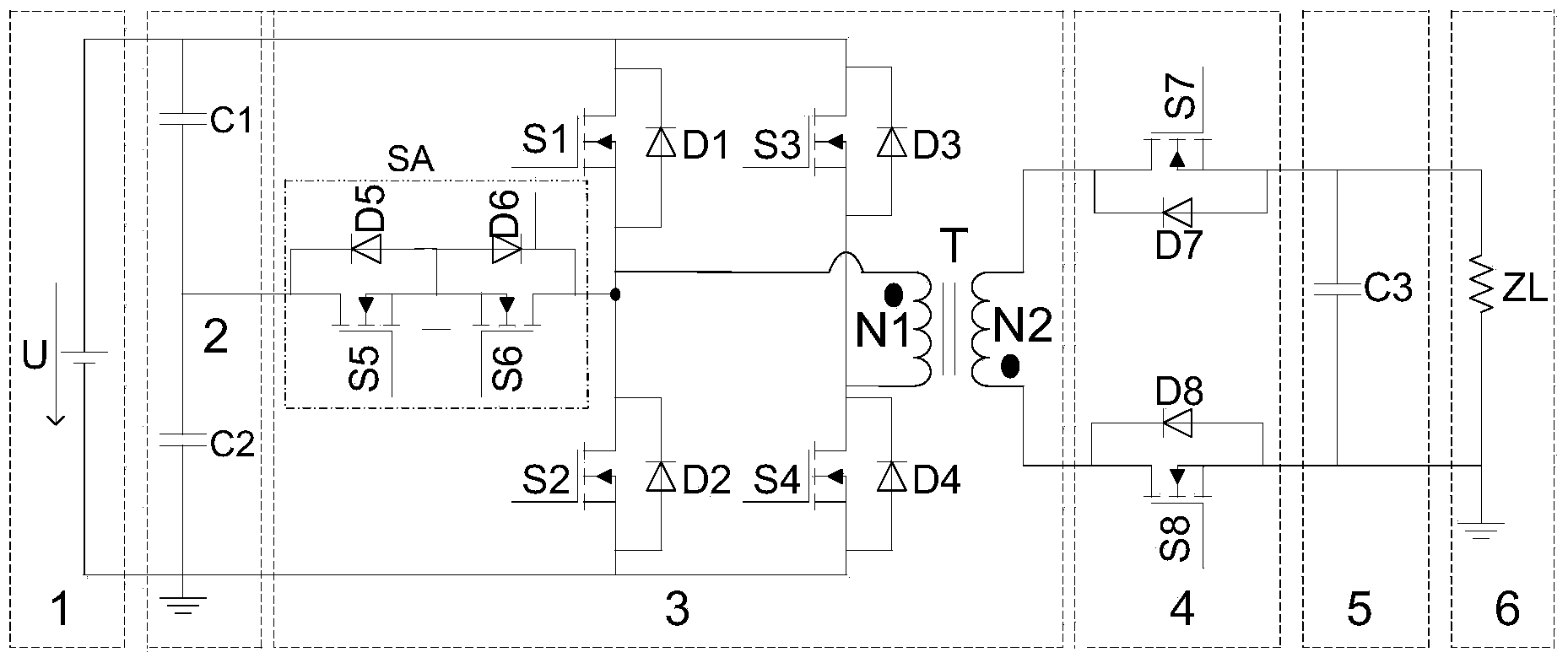

Full-bridge current-source high-frequency isolation-type three-level inverter

A three-level inverter and high-frequency isolation technology, which is applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve the problem of low power and withstand voltage of inverter switch tubes Low-level problems, to achieve the effect of small filter capacitor value, improved efficiency, and good voltage spectrum characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to better understand the technical content of the present invention, specific embodiments are given and described below in conjunction with the accompanying drawings.

[0021] figure 1 Shown is a circuit topology of a full-bridge current source high-frequency isolated three-level inverter according to an embodiment of the present invention, wherein, a full-bridge current source high-frequency isolated three-level inverter is composed of The connected input DC power supply unit 1, the voltage dividing capacitor 2, the full-bridge current source type high-frequency isolated three-level conversion unit 3, the cyclic converter 4, the output filter 5 and the output AC load 6 are formed, wherein: the input DC power supply Unit 1 is connected to one end of the voltage dividing capacitor 2, the other end of the voltage dividing capacitor 2 is connected to one end of the high-frequency isolated flyback three-level conversion unit 3, and the other end of the high-frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com