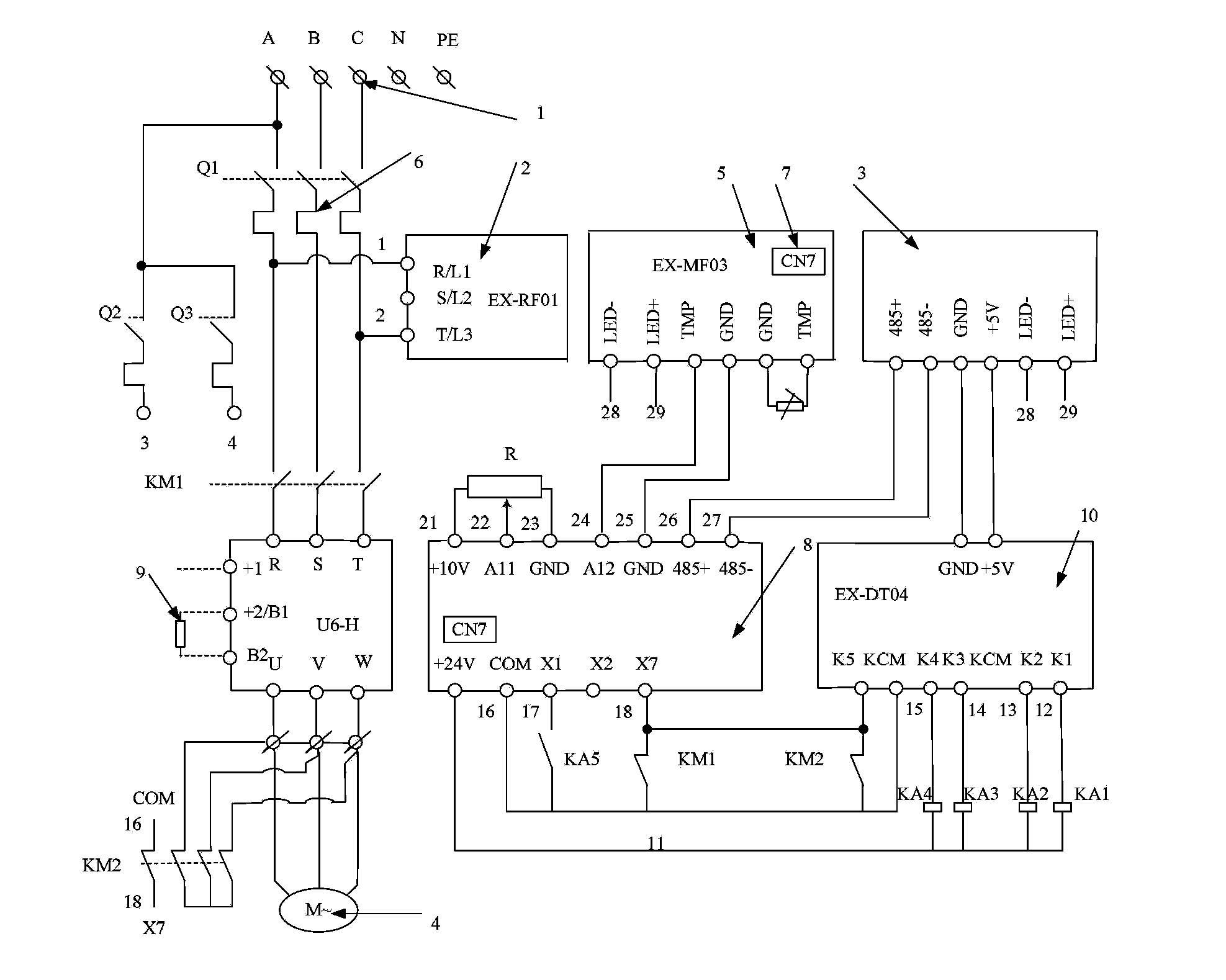

Control system for permanent magnet synchronous motor

A permanent magnet synchronous motor and control system technology, applied in the control system, vector control system, motor generator control, etc., can solve the problems of increasing reactive power loss of devices, restricting the scope of use, and grid interference, etc., to increase reactive power loss , Increase environmental adaptability, quick response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] When the system is running, close the air switch on the external operation control panel, supply power to the rectifier circuit through the three-phase AC power supply, adjust the speed setting button on the external operation control panel, and set the speed as required, and the set speed is transmitted to the digital control circuit through the bus Form the speed command. Press the start button on the external operation control panel, and the start command is sent to the digital control circuit, so that the rectifier circuit and inverter circuit start to work, and provide three-phase power with variable frequency and voltage amplitude to the permanent magnet synchronous motor. Accelerate to the set speed according to a certain acceleration time. When it is necessary to stop the motor, press the stop button on the external operation control panel, and the stop command is sent to the digital control circuit to make the rectifier circuit and inverter circuit work, reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com