Stuffing feeding tray and off-line stuffing feeding device with same

A technology for trays and fillings, applied in application, baking, dough handling, etc., can solve problems such as inconvenience, and achieve the effects of cost reduction, accurate and reliable performance, and convenient inspection and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

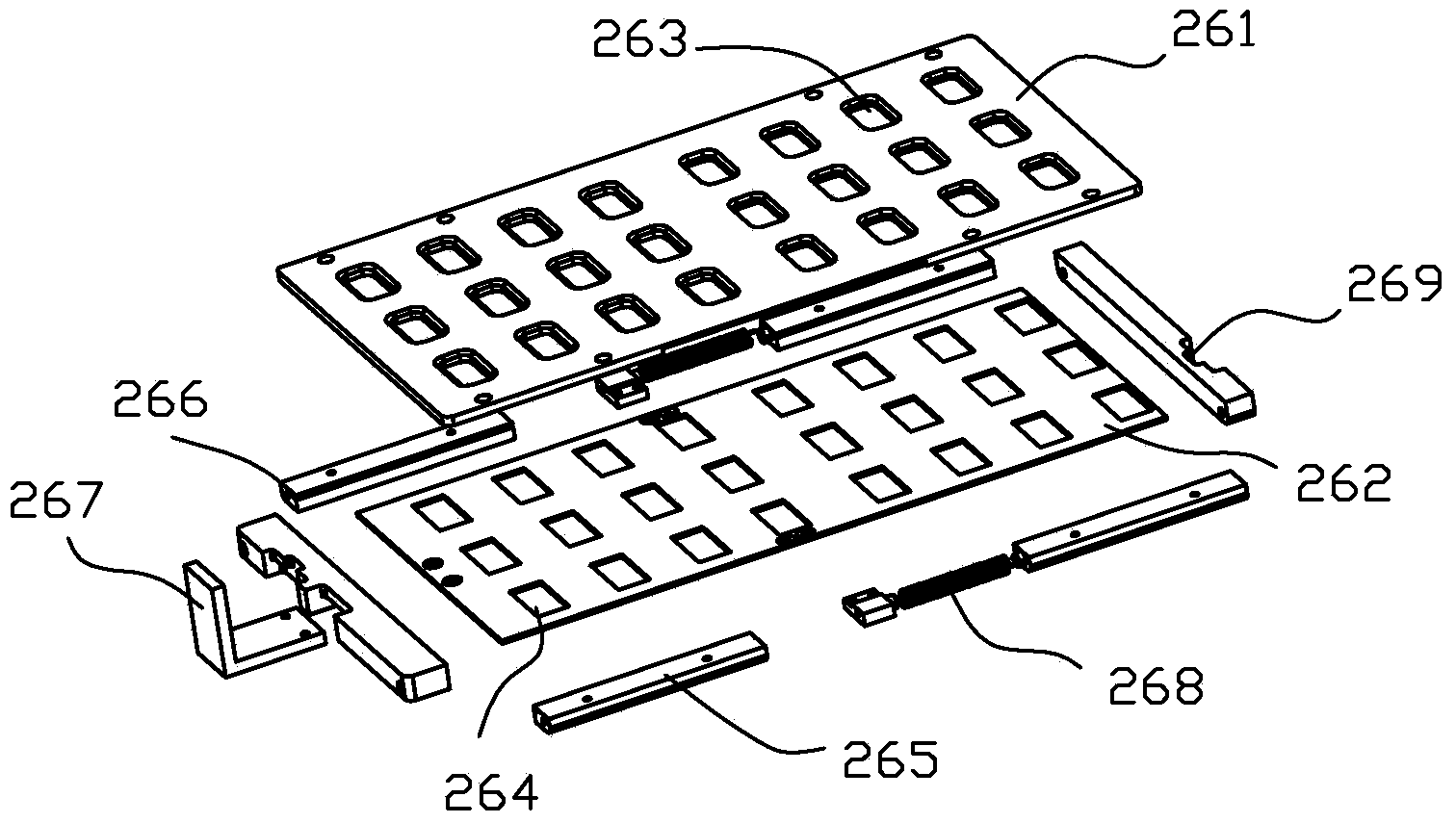

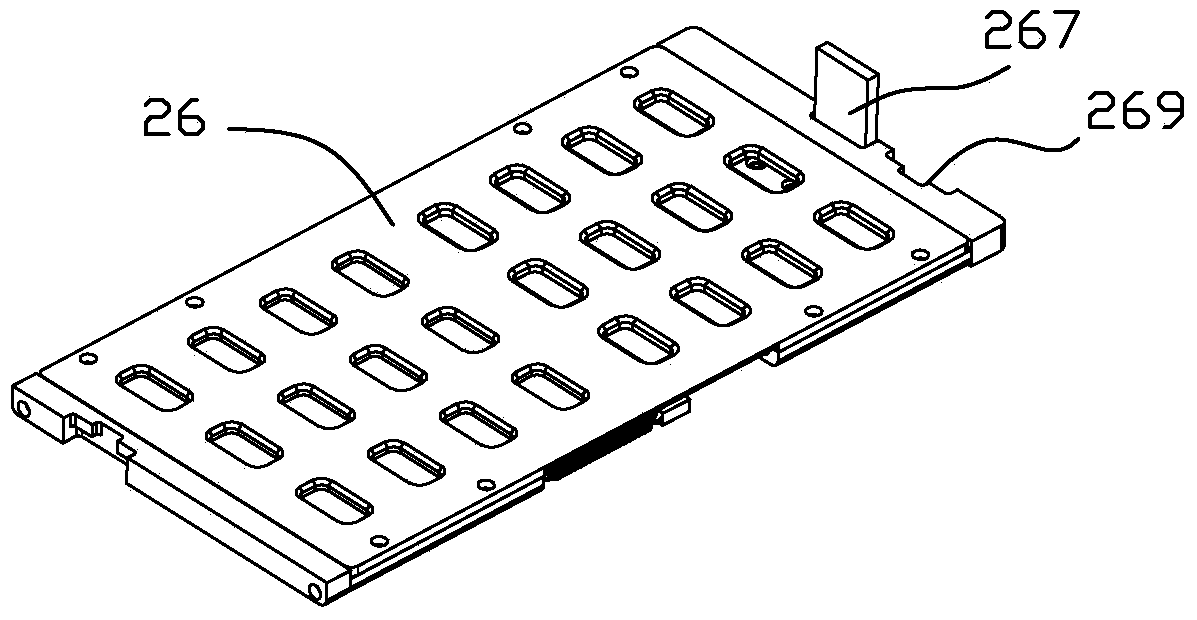

[0046] see figure 1 with figure 2 , the tray 26 comprises an upper-level cloth plate 261 and a lower-layer material baffle plate 262, the cloth plate 261 is provided with cloth holes 263 arranged in a horizontal matrix, and the distance between the cloth holes 263 in a row or column is the same as the hole in this direction along the matrix. The width is the same, and the same arrangement of the material distribution holes 263 is arranged in the same arrangement of the material baffle plate 262. The same material discharge hole 264 is arranged. Adjusting the moving link makes the distribution hole 263 and the discharge hole 204 completely staggered, partially overlapped or completely overlapped.

[0047] When the distribution plate 261 and the baffle plate 262 are stacked in the center, the distribution holes 263 and the blanking holes 264 are completely staggered, so that the distribution holes 263 are just located on the hole spacing of the material baffle plate 262, and a...

specific Embodiment 2

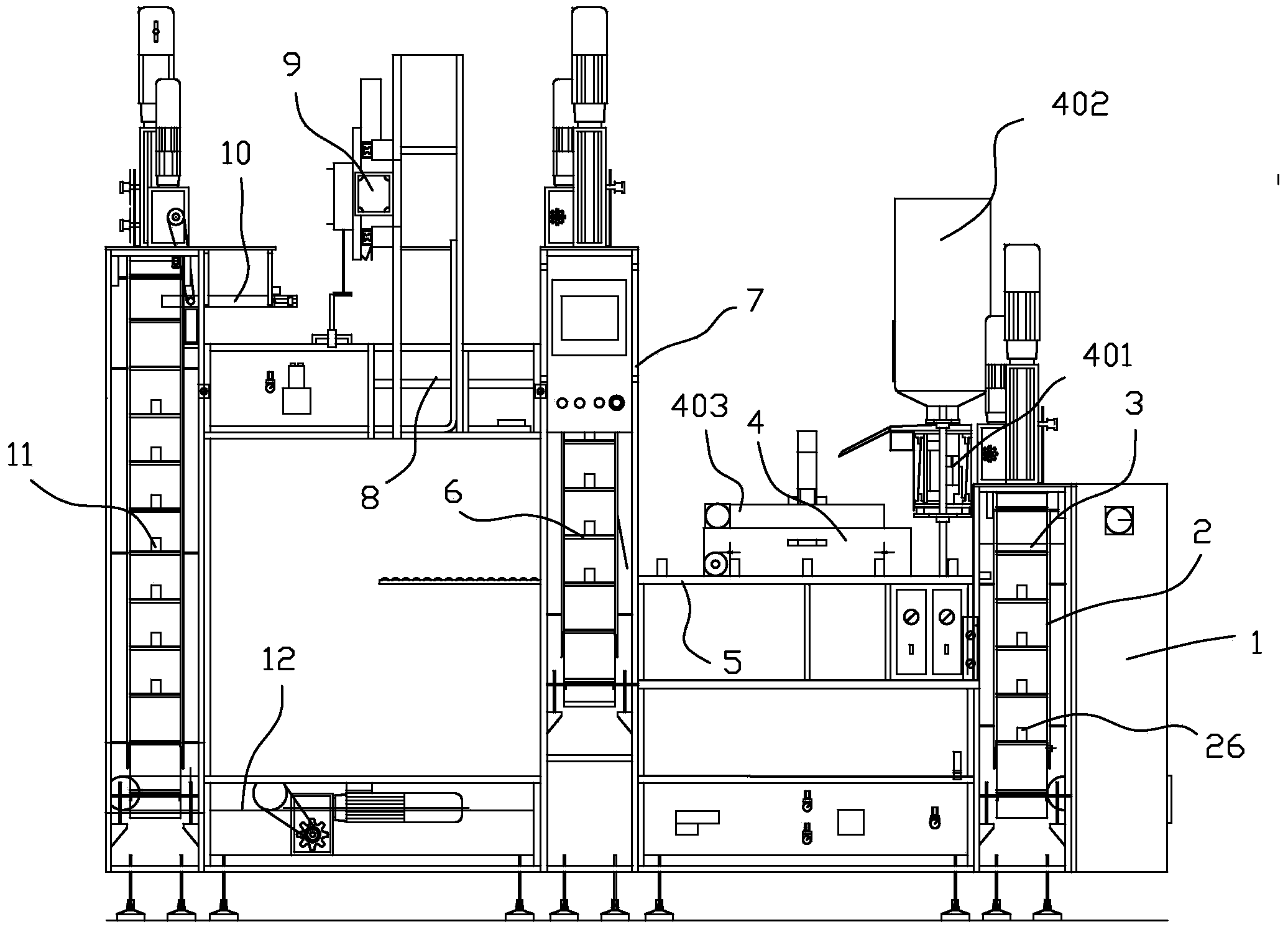

[0051] see image 3 The filling device includes the application of the filling tray. The filling device includes a frame, a conveying mechanism, a feeding mechanism 4, a discharging mechanism 9 and an electrical control system. The frame is installed next to the conveyor belt of the food production line, and the discharging mechanism 9 It includes a discharge rack 910, a translation assembly connected to the discharge rack 910, and a discharge assembly connected to the translation assembly. The discharge rack 910 has an extension 911 extending along the side of the frame, and the extension 911 is located on the conveyor belt of the food production line. above.

[0052] Such as Figure 4-Figure 6 As shown, the discharge mechanism 9 includes a discharge frame 910, a translation assembly connected to the discharge frame 910, and a discharge assembly connected to the translation assembly. The discharge frame 910 has an extension 911 extending along the side of the frame. The ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com