Low-temperature preparation method of high-protein camel milk powder

A high-protein, camel milk technology, applied in milk preparations, dairy products, applications, etc., can solve the problems of being easily damaged, unable to be produced with camel milk powder, and difficult to preserve and transport camel milk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Method steps:

[0041] 1. Add sodium caseinate to liquid milk to make the concentration reach 0.3%;

[0042] 2. Homogenize at 200bar, 60℃;

[0043] 3. Pasteurize the liquid camel milk at 70°C for 30 minutes;

[0044] 4. Use a rotary evaporator to concentrate, the concentration temperature is 65°C, and the obtained dry matter concentration reaches 50%;

[0045] 5. Low-temperature thin-layer drying: adjust the heating temperature to 65°C, open the material belt, spread the material evenly with a distributor, the thickness of the material is 2mm, adjust the movement speed of the material belt, and heat the material for 20 minutes to collect the dry material;

[0046] 6. After cooling, pulverize to obtain camel milk powder.

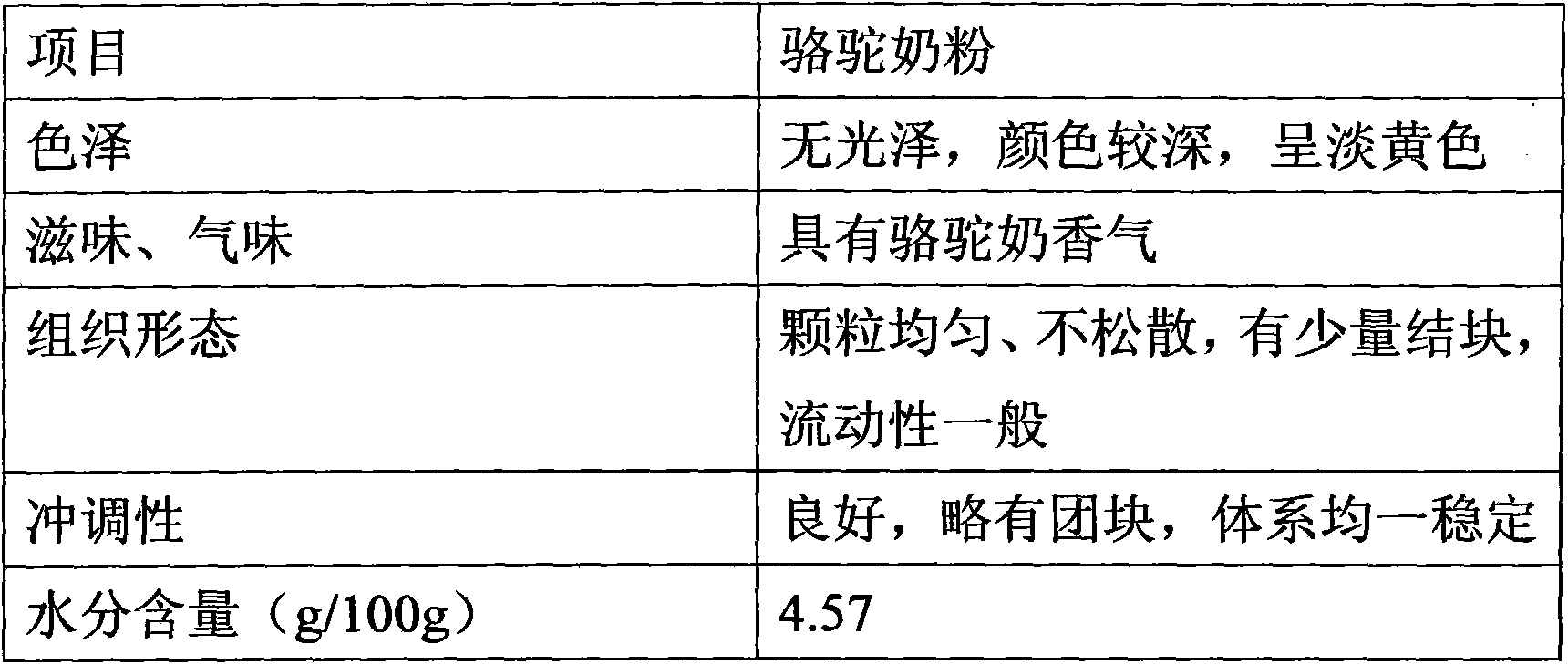

[0047] According to the method steps of the above-mentioned present embodiment, the output of camel milk powder in this embodiment is 4kg / h. In addition, the sensory quality of the produced camel milk powder is as follows in Table 1:

[0048] ...

Embodiment 2

[0051] Method steps:

[0052] 1. Add sodium caseinate to liquid milk to make the concentration reach 0.4%;

[0053] 2. Homogenize at 150bar, 65°C;

[0054] 3. Pasteurize the liquid camel milk at 70°C for 30 minutes;

[0055] 4. Use a rotary evaporator to concentrate, the concentration temperature is 70°C, and the obtained dry matter concentration reaches 60%;

[0056] 5. Low-temperature thin-layer drying; adjust the heating temperature to 60°C, open the material belt, spread the material evenly with a distributor, the thickness of the material is 2.5mm, adjust the movement speed of the material belt, heat the material for 30 minutes, and collect the dry material;

[0057] 6. After cooling, pulverize to obtain camel milk powder.

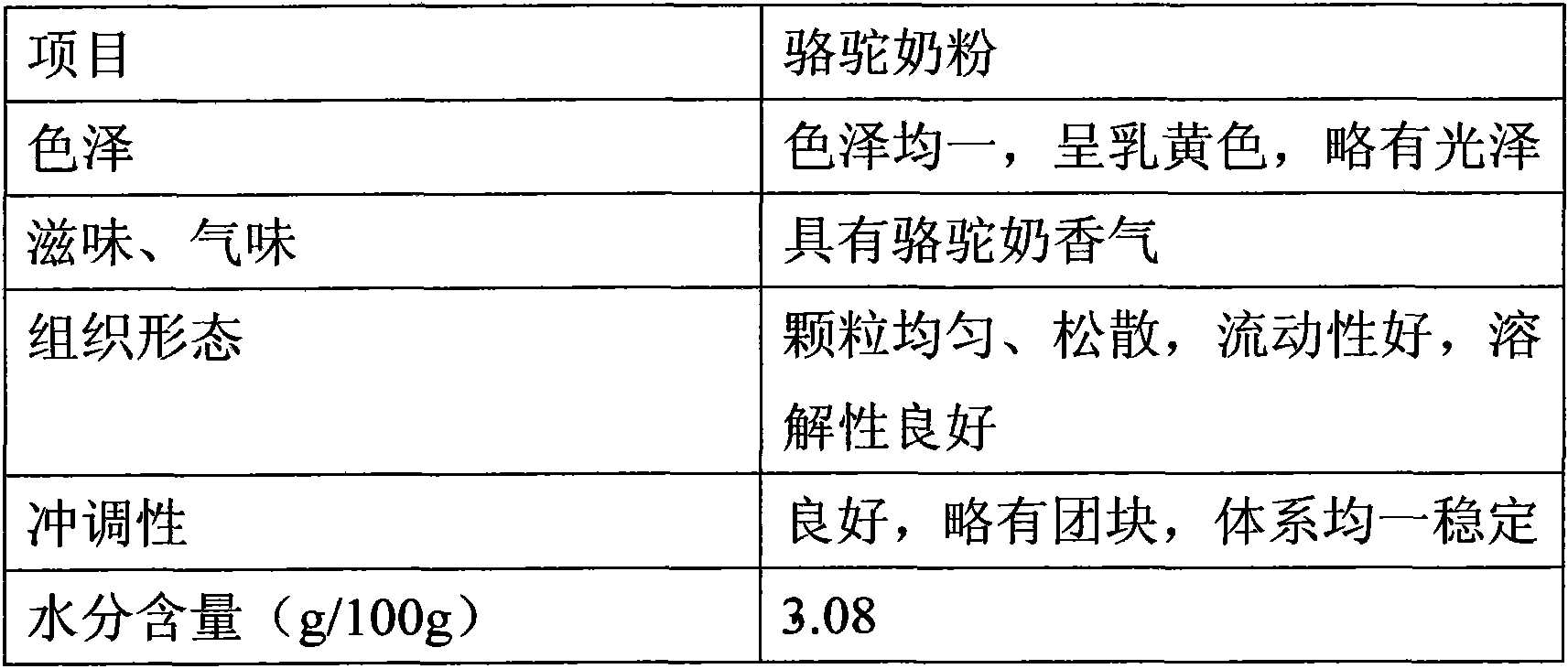

[0058] According to the method steps of the above-mentioned present embodiment, the output of camel milk powder in this embodiment is 3kg / h. In addition, the sensory quality of the produced camel milk powder is as follows in Table 2:

[0059] ...

Embodiment 3

[0063] Method steps:

[0064] 1. Add sodium caseinate to liquid milk to make the concentration reach 0.5%;

[0065] 2. Homogenize at 180bar, 70℃;

[0066] 3. Pasteurize the liquid camel milk at 65°C for 40 minutes;

[0067] 4. Use a rotary evaporator to concentrate, the concentration temperature is 65°C, and the obtained dry matter concentration reaches 40%;

[0068] 5. Low-temperature thin-layer drying: adjust the heating temperature to 70°C, open the material belt, spread the material evenly with a distributor, the thickness of the material is 1.5mm, adjust the movement speed of the material belt, heat the material for 15 minutes, and collect the dry material;

[0069] 6. After cooling, pulverize to obtain camel milk powder.

[0070] According to the method steps of the above-mentioned present embodiment, the output of camel milk powder in this embodiment is 3.5kg / h. In addition, the sensory quality of the produced camel milk powder is as follows in Table 3:

[0071]

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com