Enhanced methane control for Andrussow process

A methane gas and hydrogen cyanide technology, applied in the preparation/purification/separation of hydrogen cyanide, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of yield loss and insufficient efficiency of residual ammonia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

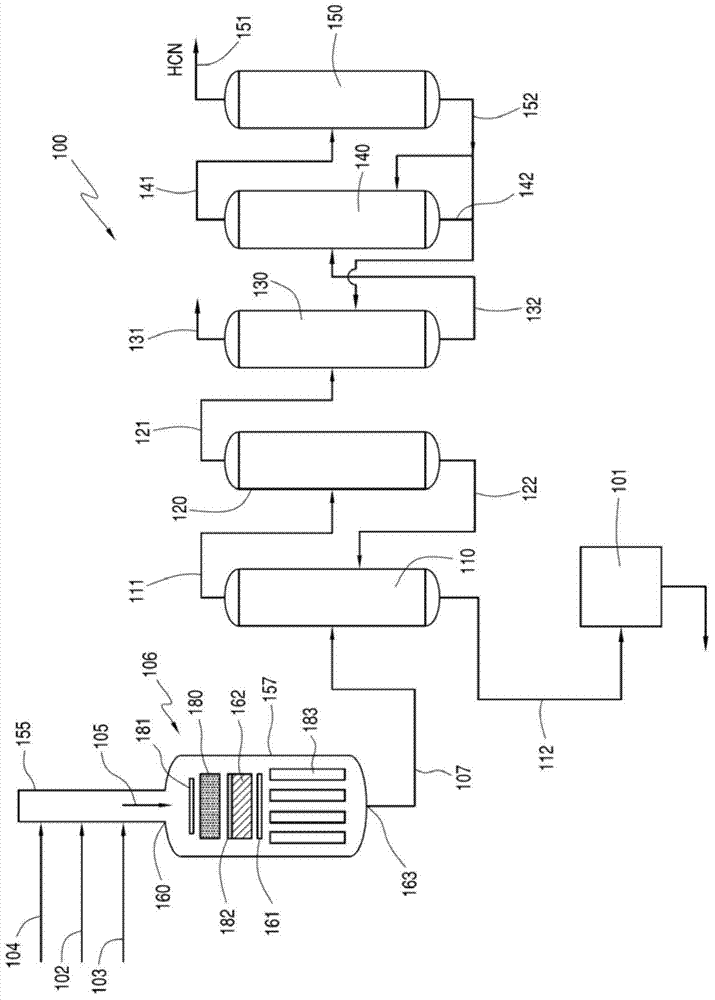

[0045] Production of methane-containing gases

[0046] As will be appreciated by those of ordinary skill in the art, the source of methane may vary and may be obtained from renewable feedstocks such as landfills, farms, biogas from fermentation, or from sources such as natural gas, petroleum-associated gas, coal gas and gas hydrate fossil fuels, such as VN Parmon, "Source of Methane for Sustainable Development", P.273-284 and Sustainable Strategies for the Upgranding of Natural Gas: Fundamentals, Challenges, and Opportunities edited by Derouane (2003 ) are further described. For the purposes of this invention, the purity of the methane and the consistent composition of the methane-containing source are important.

[0047] As a source of methane for methane-containing gases, natural gas is an impure state of methane. That is, natural gas is a substantially methane-containing gas that can be used to provide carbon atoms for the HCN produced in the process of the present inve...

Embodiment 1

[0087] According to the Andrussow method, air is used as an oxygen-containing gas to form a ternary mixed gas to produce crude hydrogen cyanide product. The ternary mixed gas is passed through the catalyst bed to form the crude hydrogen cyanide product. The methane content of the crude hydrogen cyanide product was measured as it exited the reactor unit. Such as image 3 As shown, as the concentration of methane in the crude cyanide product increases, the concentration of acetonitrile also increases. This tendency for increased nitrile formation is also to be expected when pure oxygen is used instead of air as the feed gas.

Embodiment 2

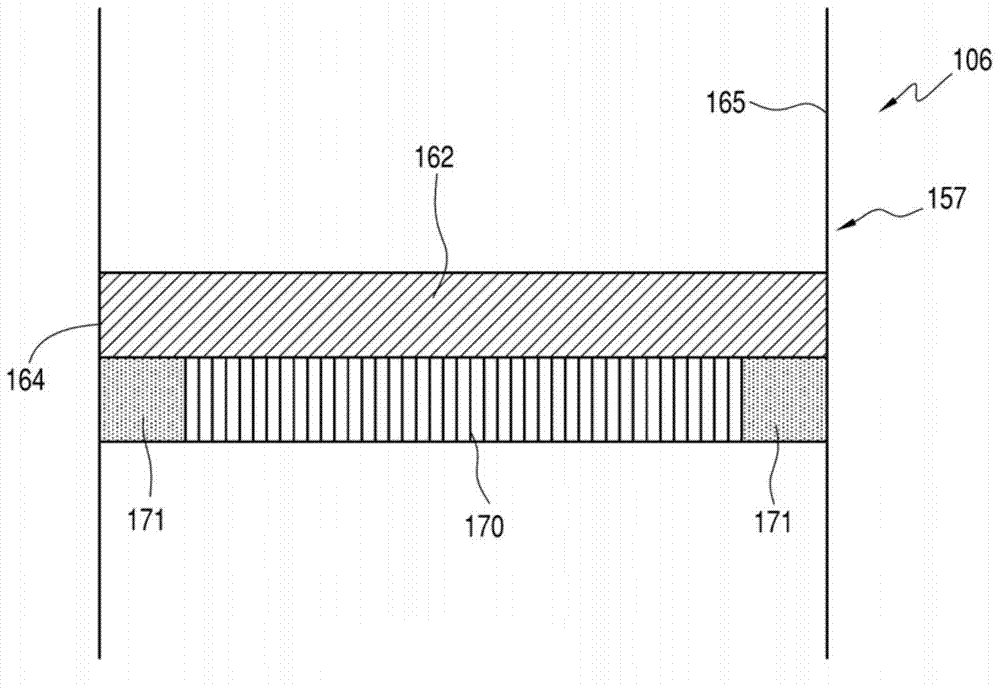

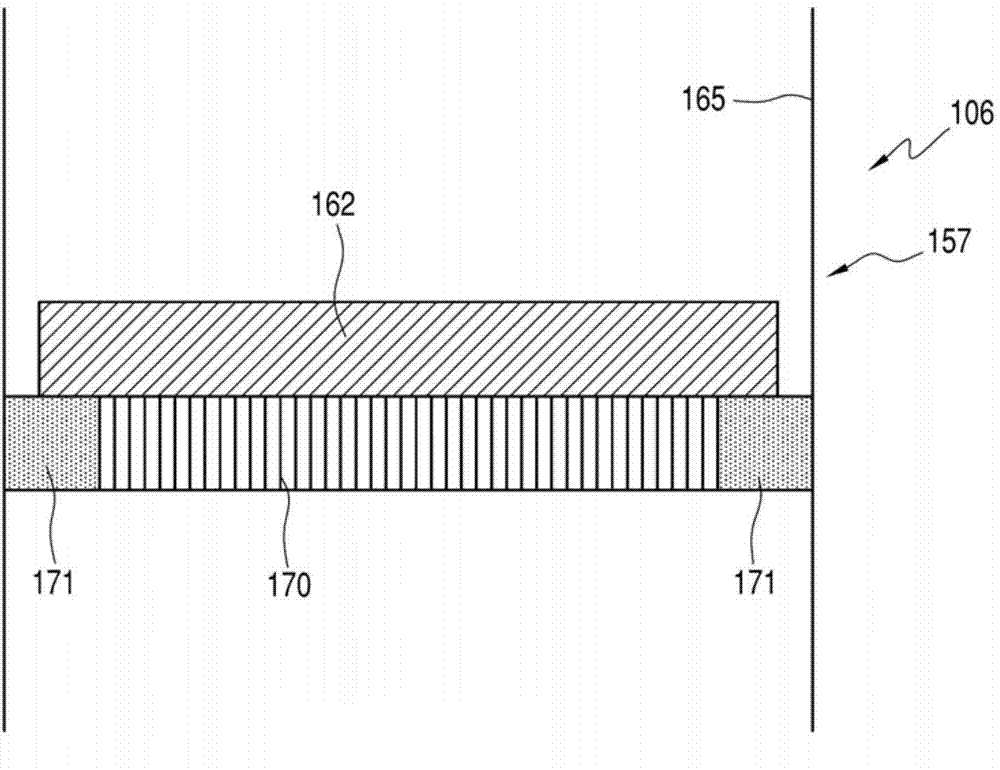

[0089] According to the Andrussow method, pure oxygen is used as an oxygen-containing gas to form a ternary mixed gas to produce crude hydrogen cyanide product. The ternary mixed gas is formed using a molar ratio of ammonia to oxygen of 1.3:1 and a molar ratio of methane to oxygen of 1.2:1. The ternary gas mixture contained 28.5% by volume of oxygen. The reactor had an internal diameter of 142.2 cm and the platinum / rhodium catalyst bed was mounted on a cast annular support extending 2.86 cm into the reactor such that the catalyst bed formed a 90% pass zone for the crude hydrogen cyanide product. During 150 days of continuous operation, the diameter of the catalyst bed shrunk by 0.64 to 1.26 cm without methane bypassing the catalyst bed because the annular support supported the shrunk catalyst bed. The crude cyanide product contains 0.2-0.3% by volume of methane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com