A production equipment and process for catalytic hydrogenation of 4-aminodiphenylamine

A technology for catalytic hydrogenation of aminodiphenylamine, applied in the field of p-phenylenediamine rubber anti-aging agent intermediates, can solve the problems of expensive catalysts, reduce deterioration and consumption, save energy consumption and equipment investment, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

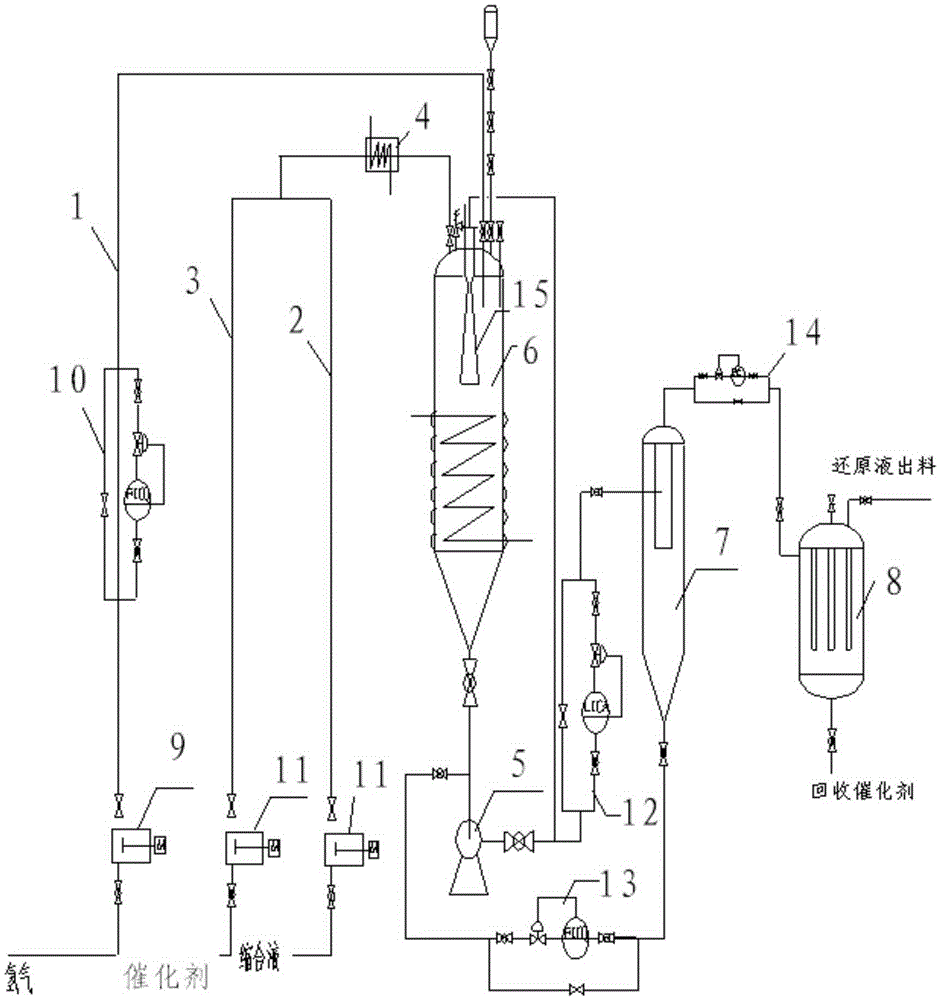

[0034] Embodiment (industrialized device embodiment)

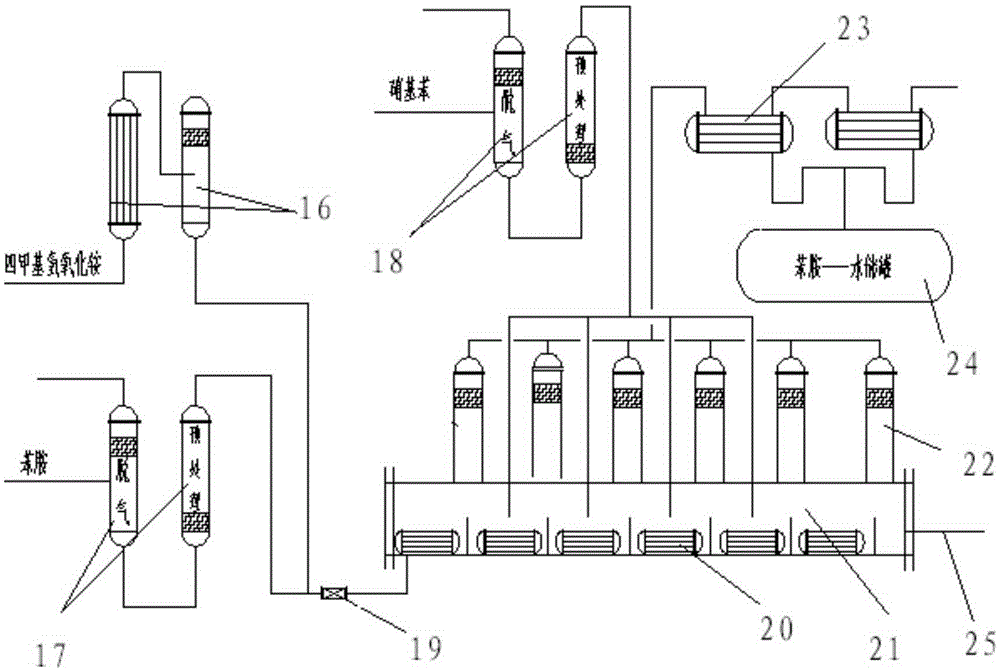

[0035] 1. Preparation of condensation solution (complex formed by 4-nitrosodiphenylamine and 4-nitrodiphenylamine and quaternary ammonium tetramethylammonium hydroxide catalyst), see attached figure 2 :

[0036] First, turn on the nitrobenzene, aniline, and quaternary ammonium tetramethylammonium hydroxide catalyst delivery pumps to control the flow rate of aniline to 13.2 cubic meters per hour and the flow rate of nitrobenzene to 2 cubic meters per hour through flow adjustment, respectively passing through the catalysts filled with alkali metal hydrogen Vacuum degassing washing tank treatment of oxides (30%NaOH), the purpose is to remove the acidic substances dissolved and adsorbed in the raw materials and some gases that are not conducive to the condensation reaction of nitrobenzene and aniline, after alkali metal hydroxide treatment and degassing The final nitrobenzene (added at 4 points in different positions of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com