Terminal alkenyl unsaturated acid/ester polyoxyalkyl ether, and preparation method and use thereof

An ester polyoxyalkyl ether, unsaturated technology, applied in the field of polyoxyalkyl ether and its preparation, can solve the problems of product separation and refining difficulties, increase production cost, increase the complexity of production process, etc., and achieve the reduction of process steps , Saving raw materials, exempting the effect of separation operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Add 60.00g hydroxyethyl methacrylate, 0.24g KOH catalyst and 0.49g p-hydroxyanisole polymerization inhibitor into the autoclave, heat up to 60°C, add 182.57g ethylene oxide, and control the reaction temperature to 80- 90°C, the reaction pressure is 0.3MPa. After the addition of ethylene oxide, continue the reaction until the reaction pressure no longer drops, stop heating, cool the material to 60-70°C and discharge, to obtain the final ethylenically unsaturated acid / ester polyoxyalkyl ether product.

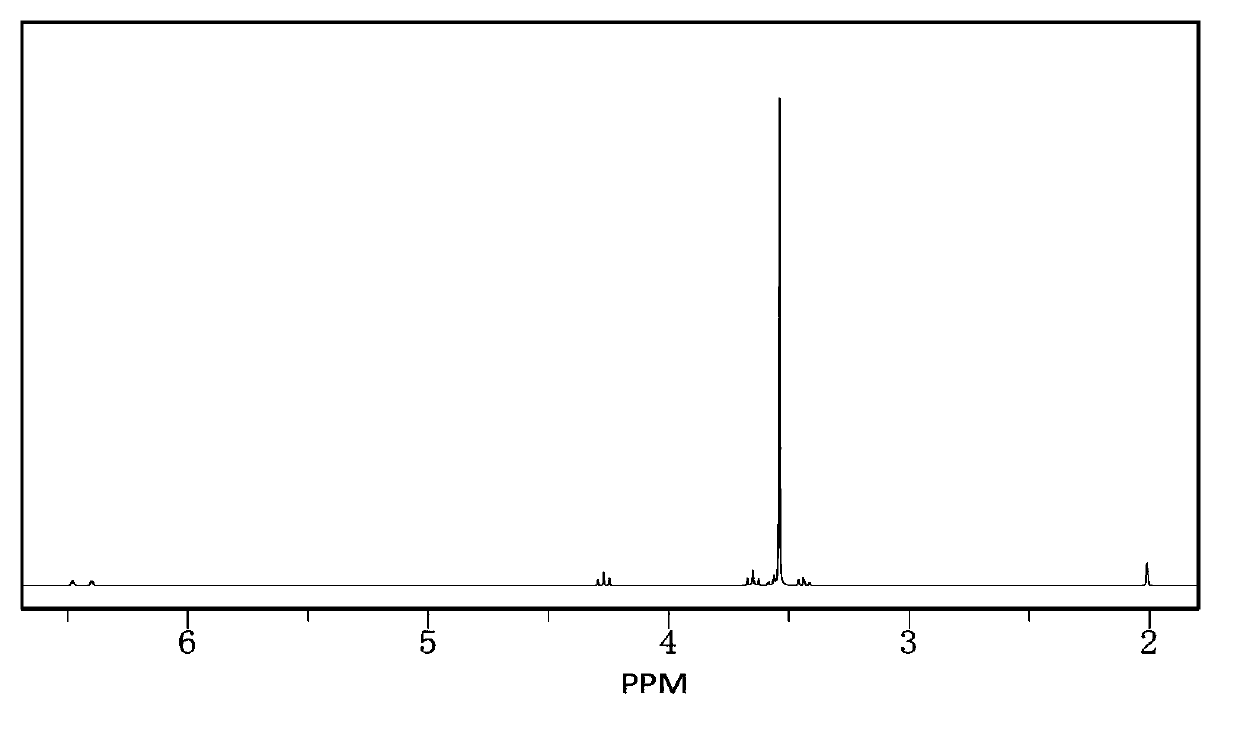

[0044]According to GPC analysis (30° C., using polyethylene glycol as a standard product to convert the molecular weight), the number average molecular weight of the product is 510.09 g / mol, and the weight average molecular weight is 580.42 g / mol. DAWN HELEOS Ⅱ produced by Wyatt Company was used for the determination, and OHpak SB-802.5HQ gel chromatographic column produced by Shodex Company was used. In the following examples, when measuring at 30°C, it is all carried ou...

Embodiment 2

[0048] Add 60.00g hydroxyethyl methacrylate and 0.92g potassium methylate catalyst and 0.46g / 0.46g hydroquinone / p-hydroxyanisole polymerization inhibitor into the autoclave, heat up to 60°C, add 401.11g epoxy Propane, control the reaction temperature to 90-100°C, and the reaction pressure to 0.3MPa. After the addition of propylene oxide, continue the reaction until the reaction pressure no longer drops, stop heating, cool the material down to 60-70°C and discharge, to obtain the final ethylenically unsaturated acid / ester polyoxyalkyl ether product.

[0049] According to GPC analysis, the number average molecular weight of the product was 956.36 g / mol, and the weight average molecular weight was 1188.48 g / mol.

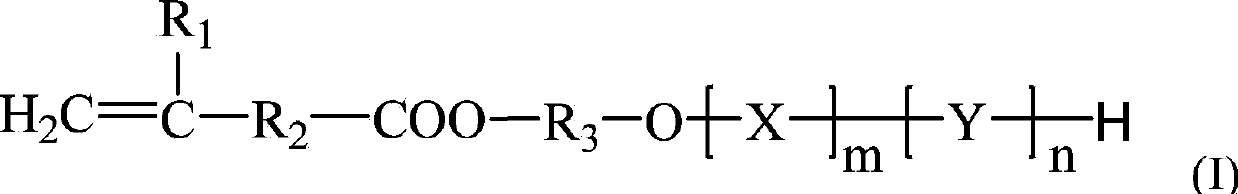

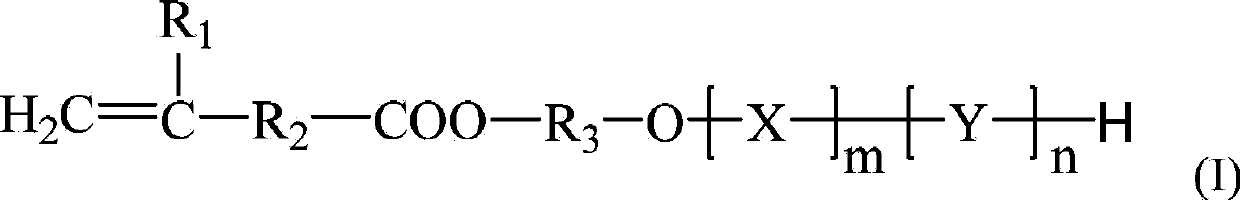

[0050] NMR spectrum measurement shows that the terminal ethylenically unsaturated acid / ester polyoxyalkyl ether has a structure as shown in formula (2).

[0051]

Embodiment 3

[0053] Add 60.00g of hydroxyethyl methacrylate, 2.78g of KOH catalyst and 4.64g of hydroquinone polymerization inhibitor into the autoclave, raise the temperature to 60°C, add 466.57g of ethylene oxide, and control the reaction temperature at 100-110°C , the reaction pressure is 0.3MPa. After the addition of ethylene oxide, continue the reaction until the reaction pressure no longer drops, then add 401.11 g of propylene oxide, control the reaction temperature to 90-100° C., and the reaction pressure to 0.4 MPa. After the addition of propylene oxide, continue the reaction until the reaction pressure no longer drops, stop heating, cool the material down to 60-70°C and discharge, to obtain the final ethylenically unsaturated acid / ester polyoxyalkyl ether product.

[0054] According to GPC analysis, the number average molecular weight of the product is 1929.82 g / mol, and the weight average molecular weight is 2294.52 g / mol.

[0055] NMR spectrum measurement shows that the termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com