Producing method of electrolytic copper powder

A technology for electrolytic copper powder and production method, which is applied to the improvement of process efficiency, photography process, instruments, etc., can solve problems such as affecting the quality of copper powder and consuming large natural gas energy, so as to improve quality, reduce energy consumption, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of production method of electrolytic copper powder, it carries out as follows:

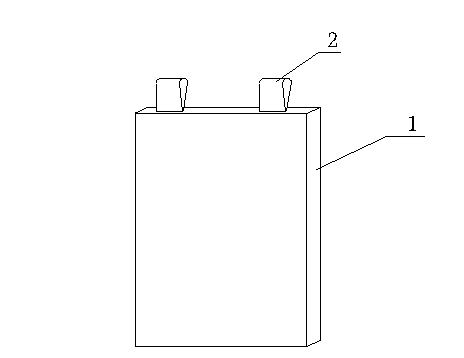

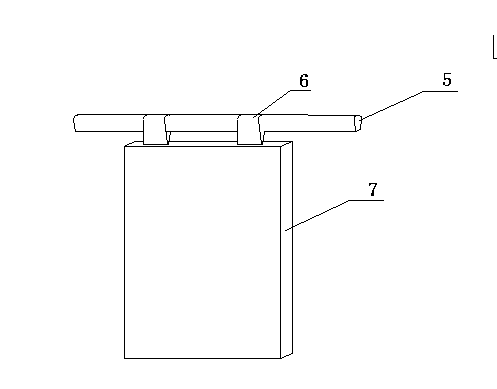

[0023] First, insert the raw material electrolytic copper plate into the conductive copper strip as the copper cathode plate, such as image 3 Shown—→Electrolysis in the electrolytic tank—→Electrolytic copper powder and mixed solution containing electrolyte—→Filtration and elutriation in the elutriation tank—→Filtration of wet electrolytic copper powder in the elutriation tank—→Water-containing electrolytic copper powder ——→Drying and reduction——→Dry electrolytic copper powder——→Crush and sieve powder——→Weighing and packaging——→Product.

[0024] The above electrolysis process uses 12 cathode plates and 13 anode plates in parallel, the concentration of copper ions in the electrolyte is 6g / L, the concentration of sulfuric acid is 133g / L, the electrolysis temperature is 45-48°C, the current in the electrolytic cell is 13000A, and the powder is scraped The time is 35 minutes / time, and ...

Embodiment 2

[0027] A kind of production method of electrolytic copper powder, it carries out as follows:

[0028] First, insert the raw material electrolytic copper plate into the conductive copper strip as the copper cathode plate, such as image 3 Shown—→Electrolysis in the electrolytic tank—→Electrolytic copper powder and mixed solution containing electrolyte—→Filtration and elutriation in the elutriation tank—→Filtration of wet electrolytic copper powder in the elutriation tank—→Water-containing electrolytic copper powder ——→Drying and reduction——→Dry electrolytic copper powder——→Crush and sieve powder——→Weighing and packaging——→Product.

[0029] The above electrolysis process uses 12 cathode plates and 13 anode plates connected in parallel, the copper ion concentration in the electrolyte is 5g / L, the sulfuric acid concentration is 150g / L, the electrolysis temperature is 50°C, the current in the electrolytic cell is 13000A, and the powder scraping time is 30 minutes / time, the electr...

Embodiment 3

[0032] A kind of production method of electrolytic copper powder, it carries out as follows:

[0033] First, insert the raw material electrolytic copper plate into the conductive copper strip as the copper cathode plate, such as image 3 Shown—→Electrolysis in the electrolytic tank—→Electrolytic copper powder and mixed solution containing electrolyte—→Filtration and elutriation in the elutriation tank—→Filtration of wet electrolytic copper powder in the elutriation tank—→Water-containing electrolytic copper powder ——→Drying and reduction——→Dry electrolytic copper powder——→Crush and sieve powder——→Weighing and packaging——→Product.

[0034] The above electrolysis process uses 12 cathode plates and 13 anode plates connected in parallel, the copper ion concentration in the electrolyte is 7g / L, the sulfuric acid concentration is 120g / L, the electrolysis temperature is 55°C, the current in the electrolytic cell is 13000A, and the powder scraping time is 40 minutes / time, the electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com