A kind of strengthening agent for papermaking and preparation method thereof

A strengthening agent and starch technology, applied in the field of papermaking, can solve the problems of low wet strength, high cost of wet strength agent, low molecular weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 20kg of cationic polyacrylamide, 15kg of hydroxypropyl methylcellulose, 30kg of coniferyl alcohol, 15kg of polyethylene glycol with a relative molecular weight of 2000, 15kg of glyceryl stearate, 10kg of starch, 8kg of aluminum sulfate and bicarbonate Sodium 1kg, mix well at 90°C, keep warm for 2 hours;

[0027] (2) Add the product in step (1) into a four-blade propulsion mixer, stir at 80°C for 1 hour, and remove bubbles by ultrasonic to obtain a strengthening agent for papermaking.

[0028] The starch is grafted and modified by polyacrylamide, and the grafting rate is 25%.

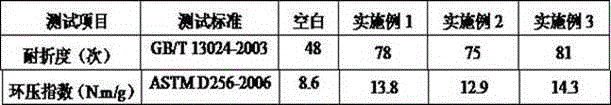

[0029] The performance test results of the prepared reinforcing agent for papermaking are shown in Table 1.

Embodiment 2

[0031] (1) Add 30kg of cationic polyacrylamide, 20kg of hydroxypropyl methylcellulose, 20kg of coniferyl alcohol, 20kg of polyethylene glycol with a relative molecular weight of 2000, 20kg of glyceryl stearate, 20kg of starch, 8kg of aluminum sulfate and bicarbonate Sodium 2kg, mix well at 100°C, keep warm for 4 hours;

[0032] (2) Add the product in step (1) to a four-blade propulsion stirrer, stir at 100°C for 2 hours, and remove bubbles by ultrasonic to obtain a reinforcing agent for papermaking.

[0033] The starch is grafted and modified by polyacrylamide, and the grafting rate is 30%.

[0034] The performance test results of the prepared reinforcing agent for papermaking are shown in Table 1.

Embodiment 3

[0036] (1) Add 25kg of cationic polyacrylamide, 15kg of hydroxypropyl methylcellulose, 20kg of coniferyl alcohol, 18g of polyethylene glycol with a relative molecular weight of 2000, 10kg of glyceryl stearate, 15kg of starch, 5kg of aluminum sulfate and bicarbonate Sodium 1kg, mix well at 95°C, keep warm for 3 hours;

[0037] (2) Add the product in step (1) to a four-blade propulsion stirrer, stir at 90°C for 2 hours, and remove bubbles ultrasonically to obtain a strengthening agent for papermaking.

[0038] The starch is grafted and modified by polyacrylamide, and the grafting rate is 35%.

[0039] The performance test results of the prepared reinforcing agent for papermaking are shown in Table 1.

[0040] Table 1

[0041]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com