Wide-beam ion source device used for ion implanter

An ion implanter and ion source technology, applied in the direction of discharge tubes, electrical components, circuits, etc., can solve the problems of wide ion beams and inability to produce them, and achieve the effects of strong beam intensity, uniformity improvement, and enlarged arc chamber size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

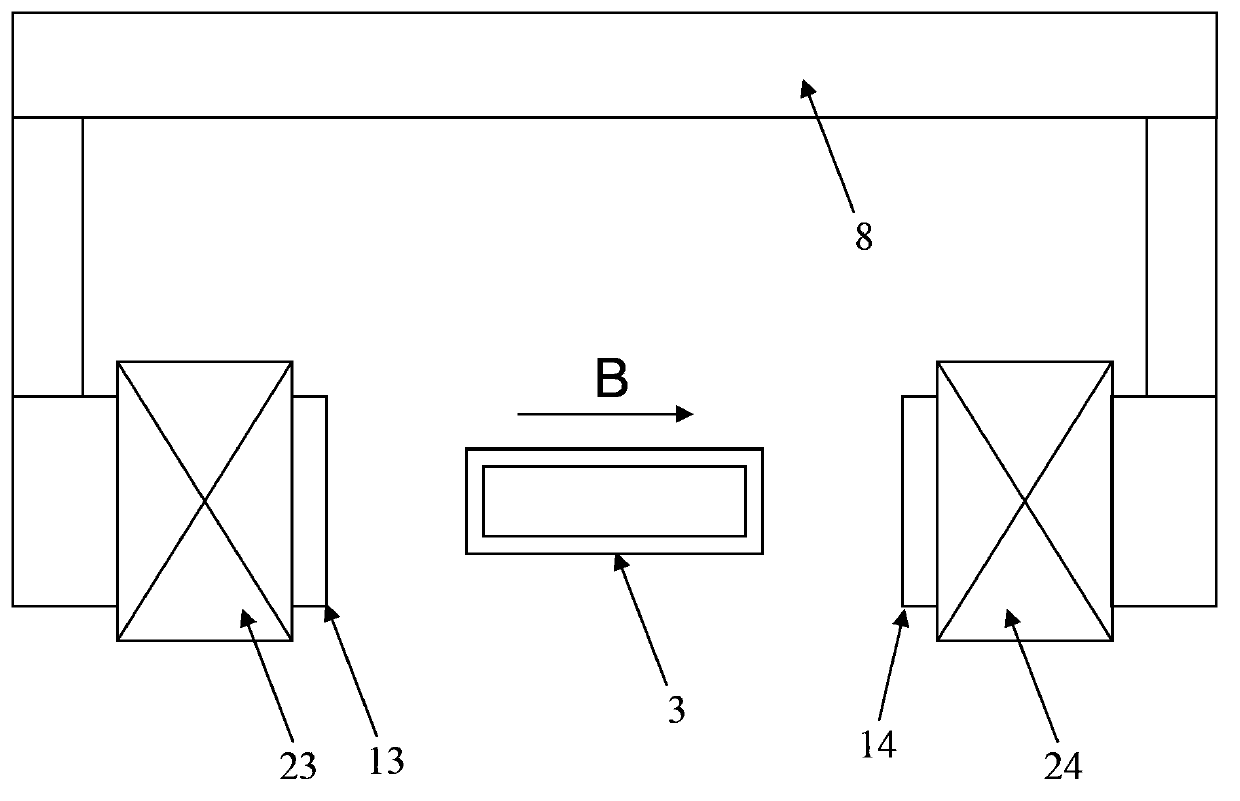

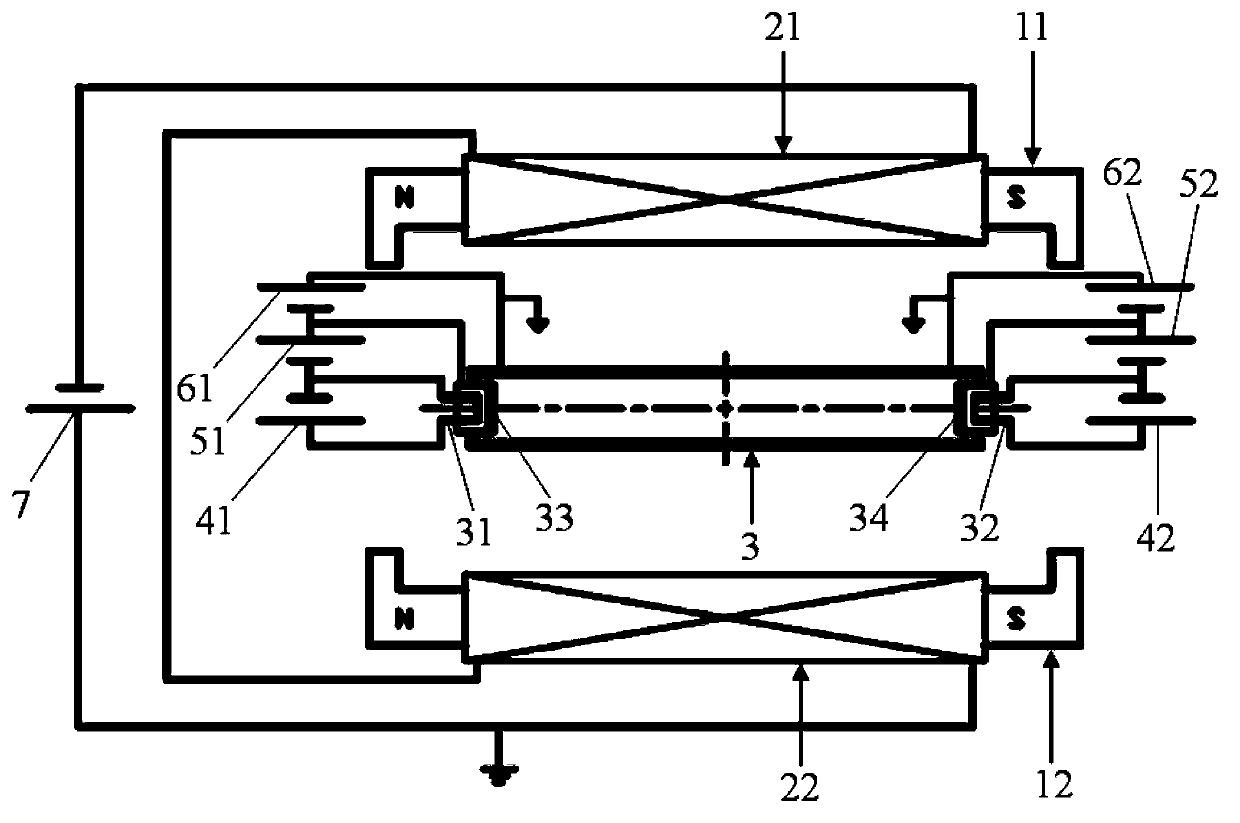

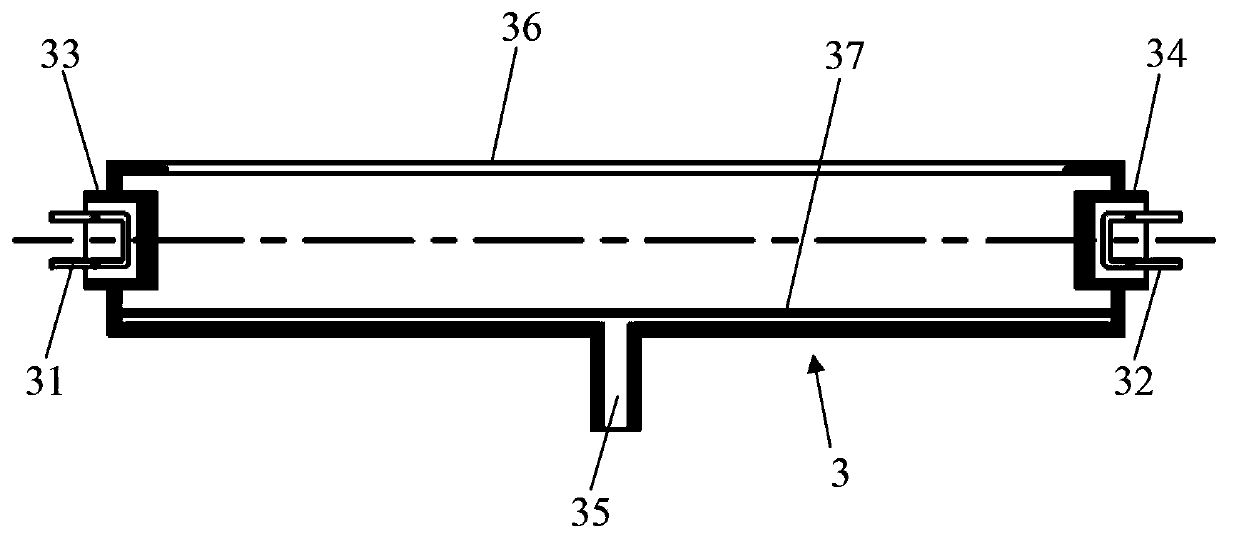

[0042] Such as Figure 2 to Figure 5 As shown, the wide-beam ion source device for an ion implanter in Embodiment 1 includes a source magnetic field iron core, a source magnetic field coil wound on the source magnetic field iron core, an arc chamber 3 and an extraction electrode 9, and the bottom of the arc chamber 3 is provided with There is an air supply hole 35, the top of the arc chamber 3 is provided with a lead-out slit 36, and the lead-out electrode 9 is arranged outside the lead-out slit 36, one end of the arc chamber 3 is provided with a first filament 31 and a first cathode 33, and the other end of the arc chamber 3 is provided with There is a second filament 32 and a second cathode 34, the first filament 31 and the second filament 32 are respectively connected to the filament power supply, the first bias power supply 51 is connected between the first filament 31 and the first cathode 33, the second filament 32 and the second The second bias power supply 52 is connec...

Embodiment 2

[0063] Such as Image 6 As shown, the difference between the wide-beam ion source device of Embodiment 2 and the wide-beam ion source device of Embodiment 1 is only that the source magnetic field coil is different, and the rest of the structures are the same. Only the differences will be described in detail below.

[0064] In order to improve the distribution of the source magnetic field, the source magnetic field with a multi-coil structure is adopted in the second embodiment. By adjusting the driving current of each coil, the uniform distribution state of the source magnetic field in the arc chamber 3 section can be further adjusted to improve the uniformity of the broadband beam current. sex distribution.

[0065] The source magnetic field iron core includes an upper iron core 11 and a lower iron core 12, the upper iron core 11 and the lower iron core 12 are arranged on both sides of the arc chamber 3, and the upper iron core 11 and the lower iron core 12 are along the len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com