High-brightness LED with surface microstructure and manufacturing and screening method thereof

A technology of light-emitting diodes and light-emitting diodes, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as the inability to define the quality of surface microstructures, and achieve the effects of weakening light extraction efficiency, high efficiency, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

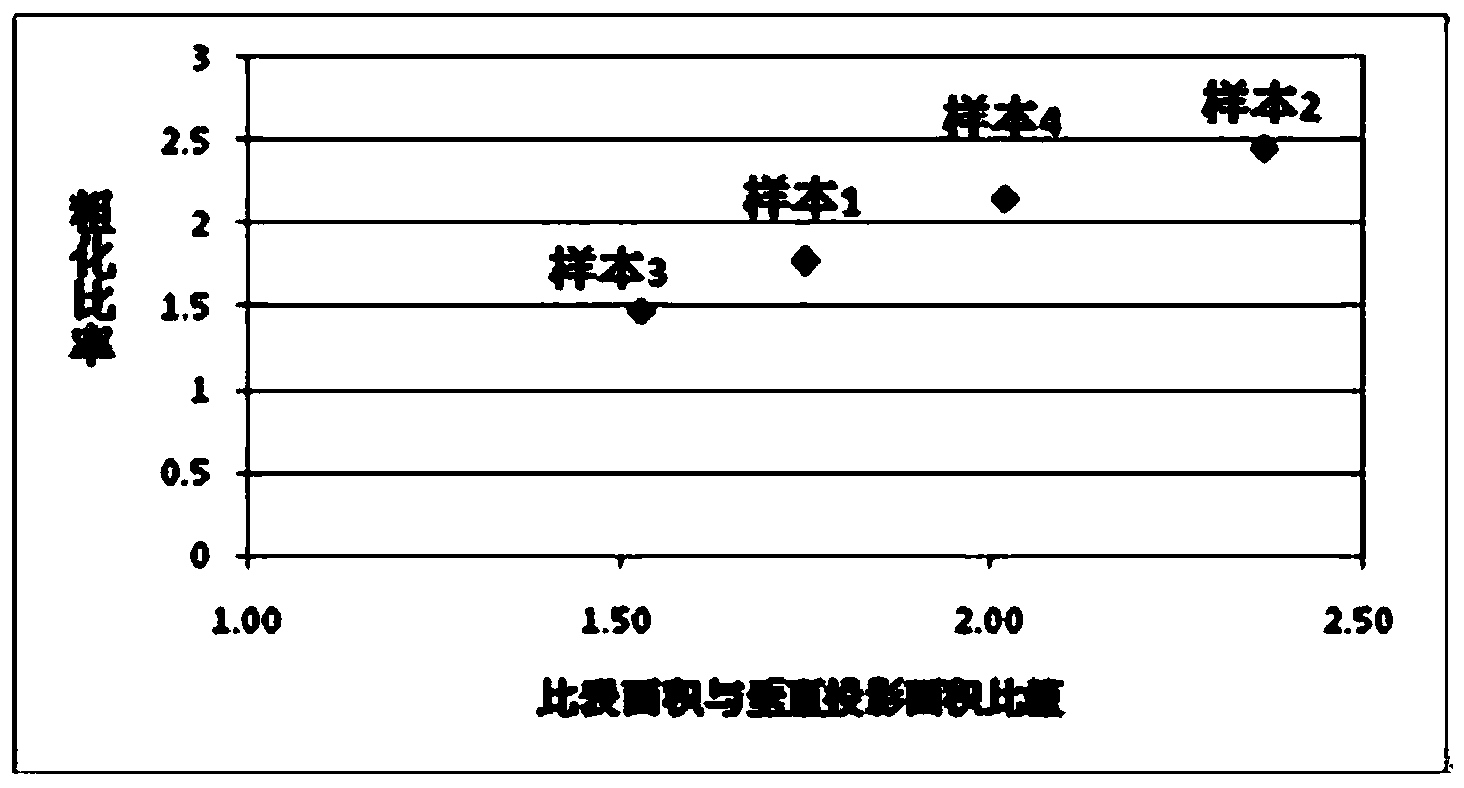

[0054] There are four samples in Example 1. Samples 1-4 are all LEDs with an N-type contact layer on the surface microstructure. The structures are basically the same. The epitaxial wafers are grown by depositing a buffer layer on the epitaxial substrate. (buffer layer) and N-type electrical contact layer, and then deposit an N-type contact layer (n-cladding), deposit a multi-layer quantum well (MQW) structure on the n-cladding, and then deposit a P-type contact layer on the MQW structure ( p-cladding), and finally the electrical contact layer to complete the growth of the epitaxial layer structure; the difference between samples 1-4 is that the materials of each corresponding functional layer are different, so that the wavelengths of light emitted by samples 1-4 are different , the specific functional layer components of samples 1-4 are detailed in Table 1 below:

[0055] Table 1 The composition of each functional layer of sample 1-4

[0056]

[0057] After the epitaxial ...

Embodiment 2

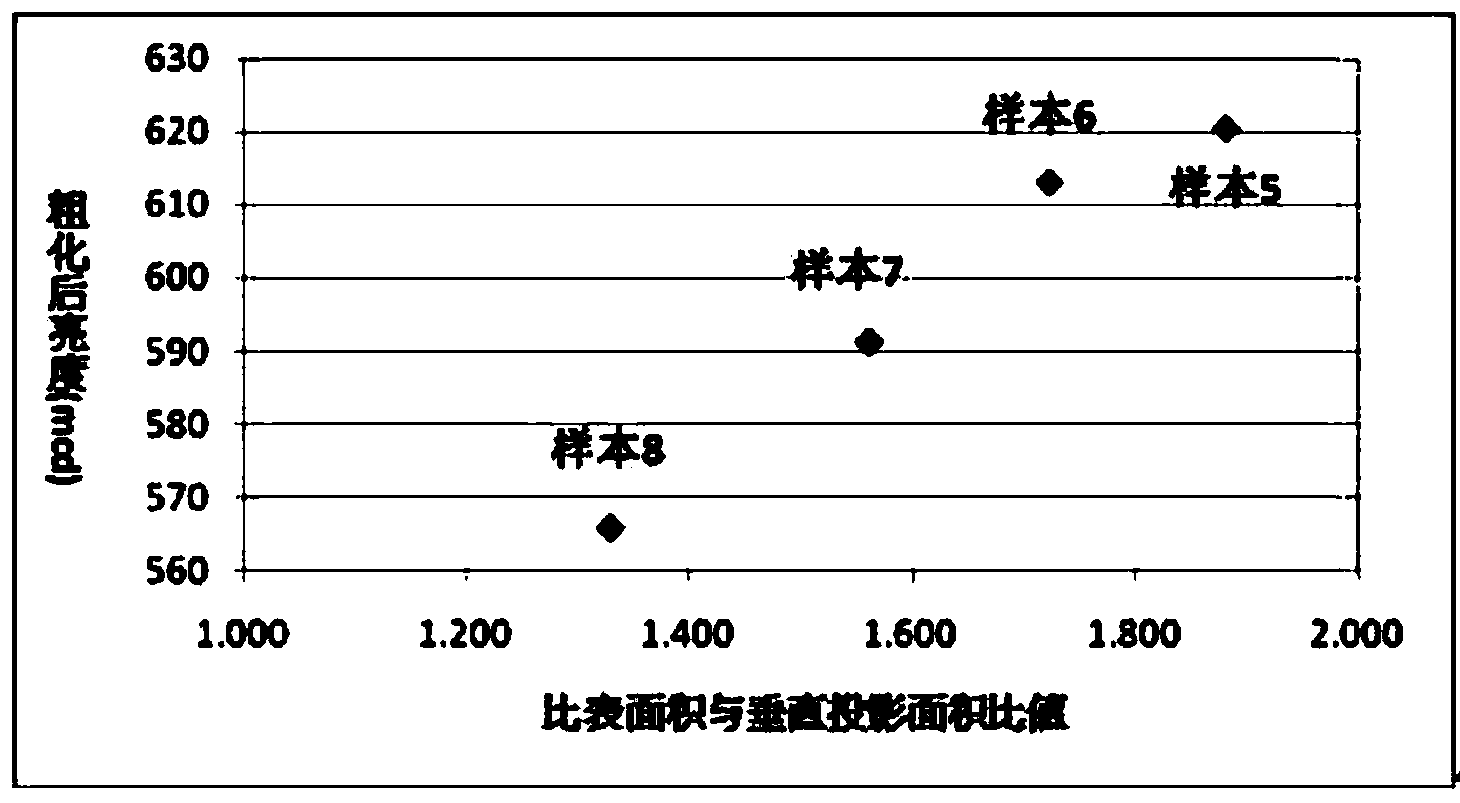

[0069] There are four samples in Example 2, and the preparation method of samples 5-8 is the same, specifically depositing a buffer layer (GaAs) and an electrical contact layer on the epitaxial substrate, and then depositing n-cladding (n-GaAs). MQW (InGaP / AlGaInP) structure is deposited on top of the n-cladding, p-cladding (p-GaP) is deposited on the MQW structure, and finally an electrical contact layer is deposited to complete the growth of the epitaxial layer structure; epitaxial wafers of samples 5-8 After the growth is completed, a wafer that can be roughened is prepared, and then the surface of the wafer is roughened to form samples 5-8 with surface microstructures.

[0070] The surface roughening treatment methods of samples 5-8 are basically the same, including the following steps:

[0071] (1) Expose the light-emitting surfaces that need to be roughened on samples 5-8, and protect the light-emitting surfaces that do not need to be roughened with photoresist or metal;...

Embodiment 3

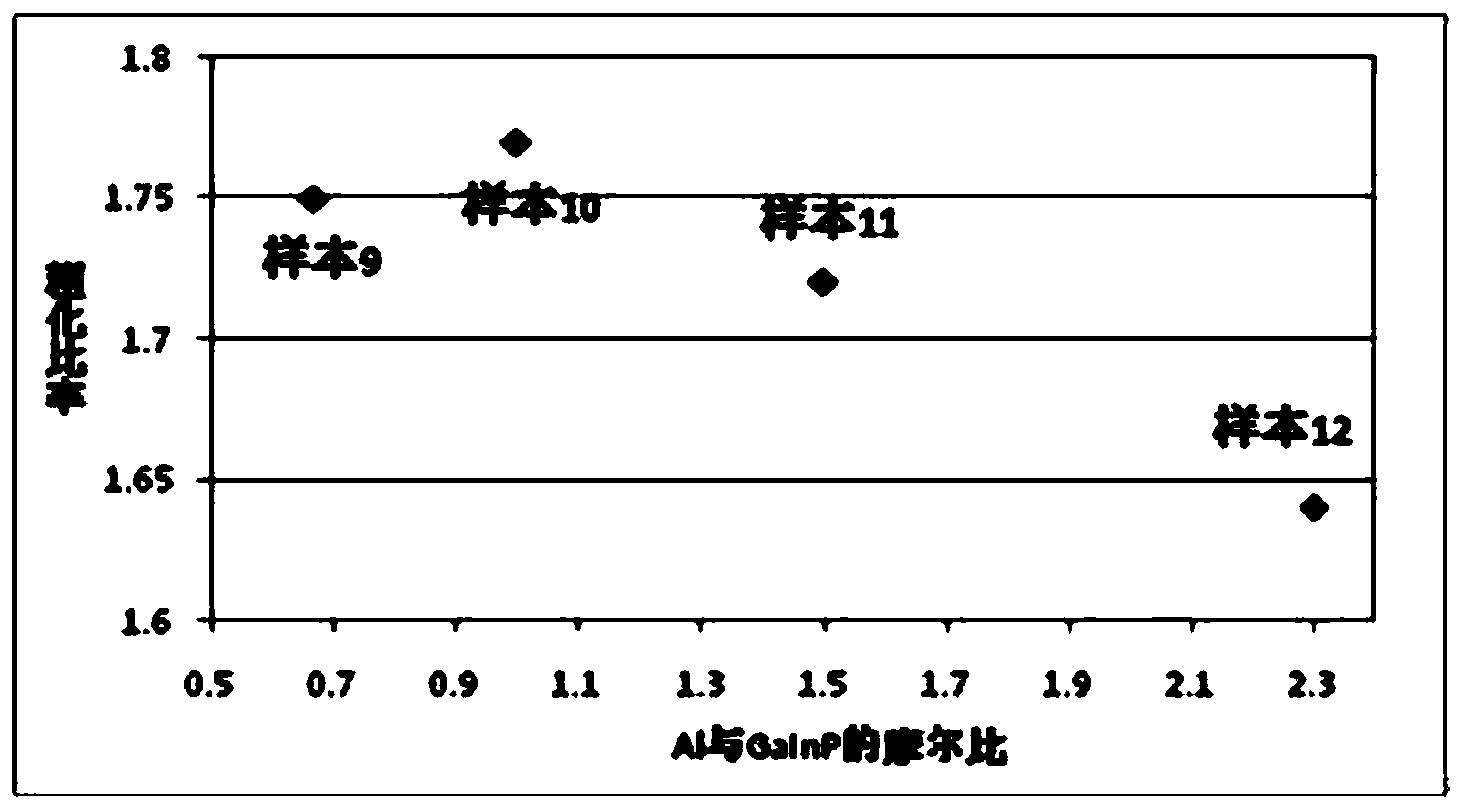

[0080] In Example 3, four samples are included. Samples 9-12 are all epitaxial wafers with a vertical structure, and the preparation method is the same. The specific preparation method is to deposit a buffer layer (GaAs) and an electrical contact layer on the epitaxial substrate, and then Deposit n-cladding (Al X (GaInP) X ), deposit an MQW (InGaP / AlGaInP) structure above the n-cladding, deposit p-cladding (p-GaP) on the MQW structure, and finally an electrical contact layer to complete the growth of the epitaxial layer structure; sample 9- After the epitaxial wafer of 12 is grown, it is prepared into a wafer that can be roughened, and then the surface of the wafer is roughened to form samples 9-12 with a surface microstructure.

[0081] The steps of the coarsening processing method for samples 9-12 are basically the same, including the following steps:

[0082] (1) The light-emitting surfaces that need to be roughened on samples 9-12 are exposed respectively, and the light-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Light intensity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com