Preparation process for Linyuan Wangying tea

A technology of Lingyuan Wanying tea and its production process, which is applied in the field of improving the production process of medical drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

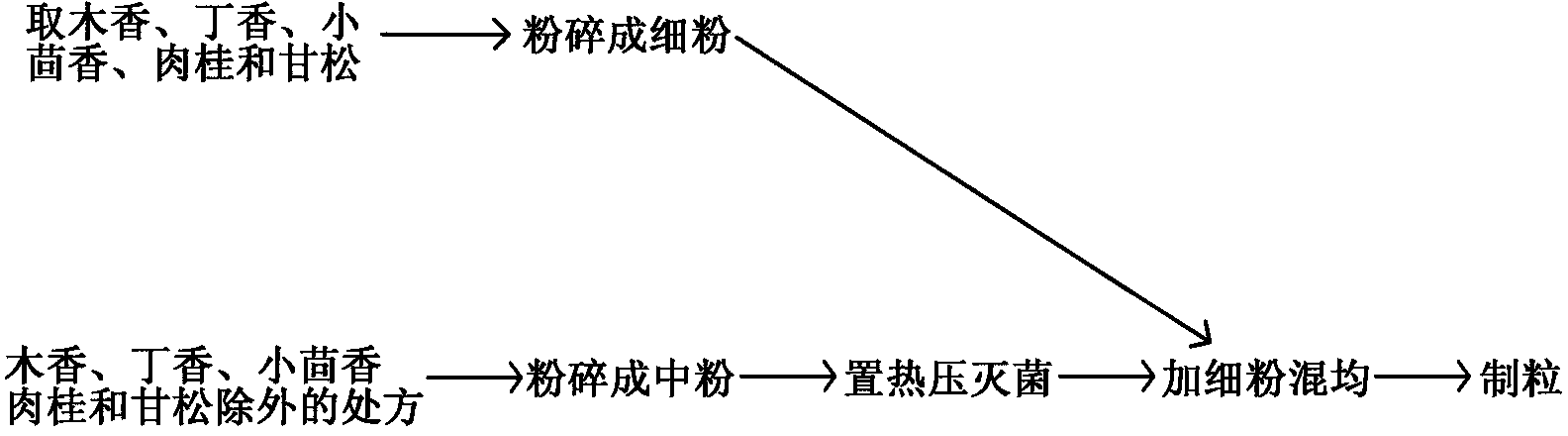

Image

Examples

Embodiment Construction

[0006] A production process of Lingyuan Wanying tea, which is characterized in that: it includes 25g woody fragrance, 5g aurantium citrus, 2.5g nepeta, 2.5g red peony, 2.5g rhubarb (made from wine), 15g nard pine, and 2.5 g trichosanthes g, 5 g betel nut, 5 g white lentils, 80 g flying grass, 5 g aurantium aurantium (made from bran), 10 g rice buds, 10 g poria cocos, 5 g tangerine peel (made from four), 2.5 g magnolia officinalis (made from ginger), cinnamon 10 g, Jue bed 50 g, iron amaranth 40 g, Pinellia (ginger) 2.5 g, licorice 50 g, patchouli 5 g, Peucedanum 2.5 g, Chuan Ketong 5 g, psyllium 5 g, malt 10 g, 5 g of Angelica dahurica, 25 g of cumin, 75 g of wild licorice, 5 g of white peony root, 2.5 g of red cardamom (made from ginger), 2.5 g of lotus leaf, 2.5 g of papaya, 2.5 g of papaya, 2.5 g of clove, 50 g Oxalis, 35 g Herba Chinensis, 25 g Ye Xia Zhu, 50 g Eclipta, 200 g Artemisia annua, 200 g black tea leaves, 5 g perilla, 2.5 g Atractylodes (stir-fried with bran), 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com