Full-automatic betel nut seed sorting and cutting integrated machine

A fully automatic, all-in-one machine technology, applied in metal processing, sorting, etc., can solve problems such as lack of consideration of betel nut continuity, equipment jamming, and reduced safety factor, so as to achieve a smooth and reasonable seed cutting process, reduced production costs, The effect of saving working time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

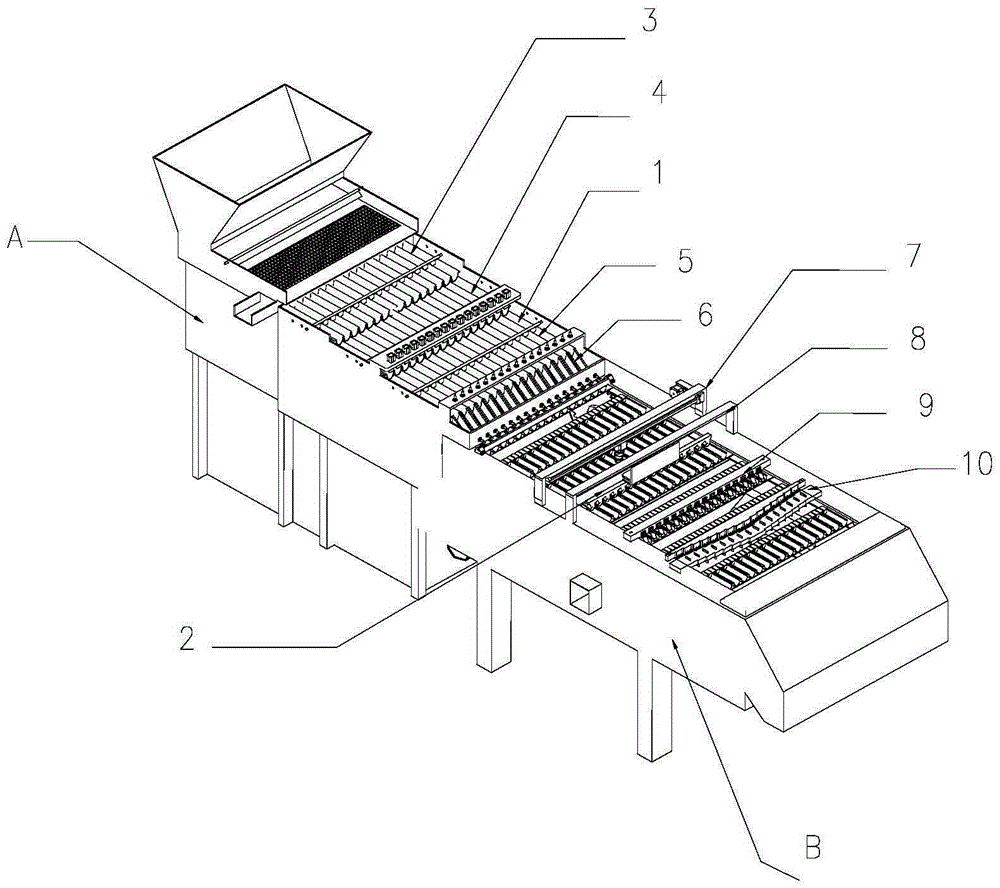

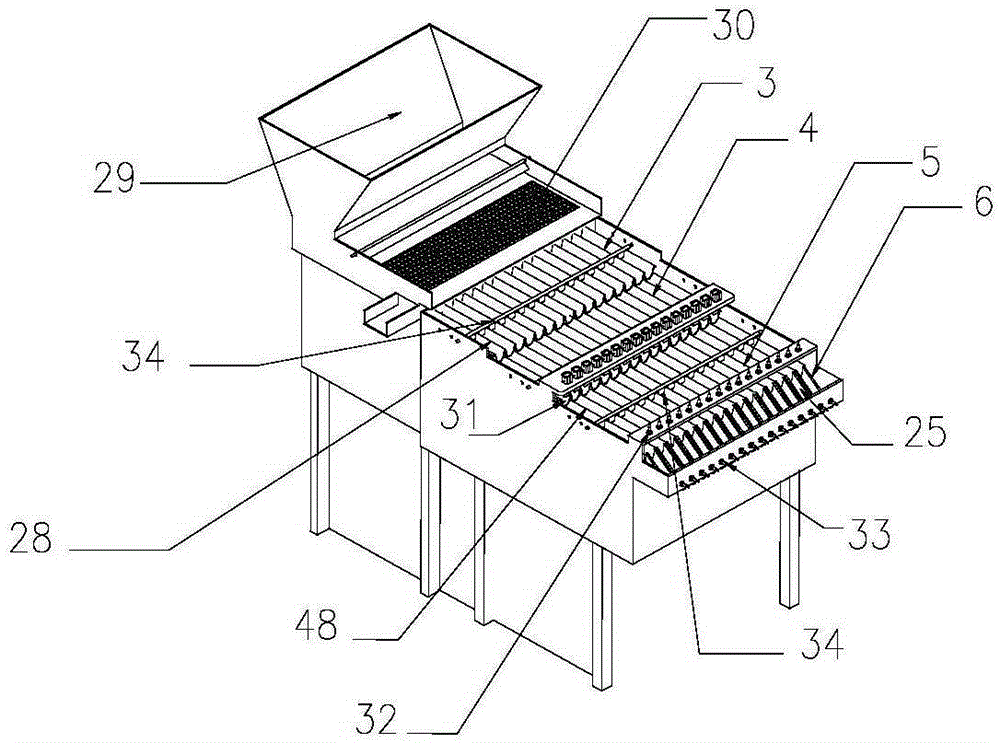

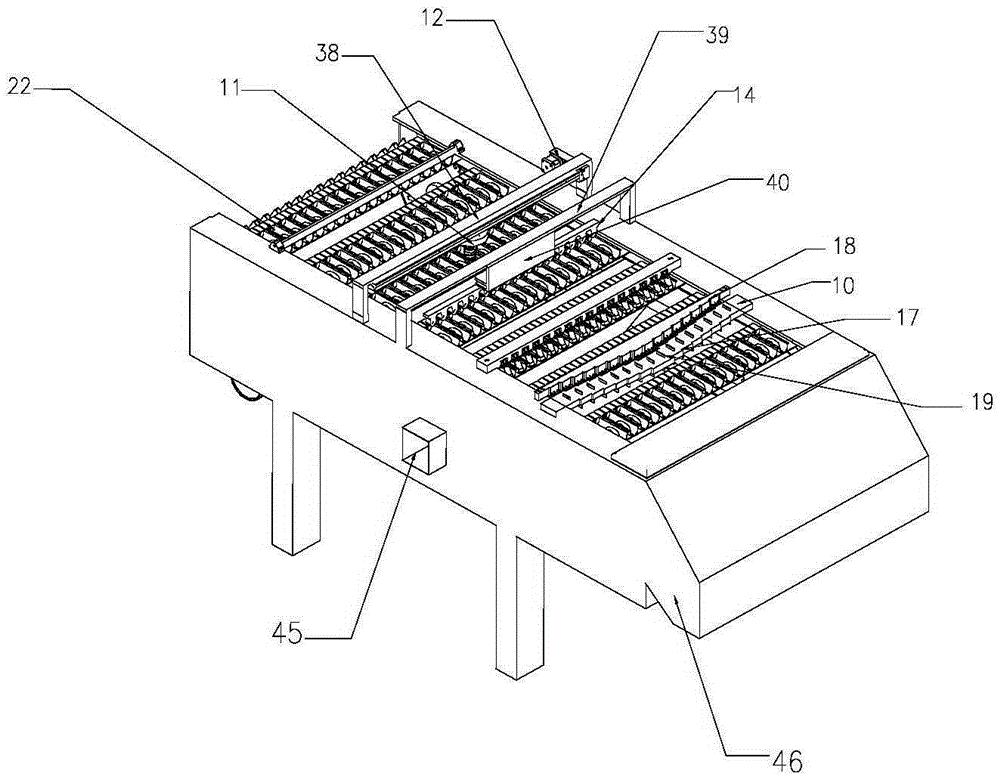

[0040] Betel nut automatic seed selection machine, such as figure 1 As shown, it includes a first frame A, a second frame B, a material sorting mechanism 1, a seed selection and cutting mechanism 2, and a control system. Such as figure 2 As shown, the material handling mechanism 1 includes a first-level vibration material management group 3, a second-level vibration material management group 4, a third-level vibration material management group 5, and a material guide groove group 6 arranged on the first frame A in sequence. . The first-stage vibration material management group 3 and the second-stage vibration material management group 4 are all made up of a vibrator 27 and a U-shaped groove plate 28 . The third stage vibrating material handling group 5 is composed of multiple groups of independent material handling units 48, and the material handling unit 48 is composed of a material management U-shaped groove 26 and an exciter 27 arranged at the bottom of the material mana...

Embodiment 2

[0044] Betel nut automatic seed selection machine, such as figure 1 As shown, it includes a first frame A, a second frame B, a material sorting mechanism 1, a seed selection and cutting mechanism 2, and a control system. Such as figure 2 As shown, on the first frame A, a hopper 29 and a vibrating screen 30 are arranged upstream of the first-stage vibrating material handling group 3 . The material handling mechanism 1 includes a first-level vibrating material-adjusting group 3 , a second-level vibrating material-adjusting group 4 , a third-level vibrating material-adjusting group 5 , and a material guide trough group 6 arranged on the first frame A in sequence. Such as figure 2 As shown, the material guide trough group 6 is composed of a material guide trough 25, and is arranged obliquely downward at the tail of the first frame A. 26 links to each other and corresponds one by one, and its lower end links to each other and corresponds one to one with the selected seed U-sha...

Embodiment 3

[0048] Betel nut automatic seed selection machine, such as figure 1 As shown, it includes a first frame A, a second frame B, a material sorting mechanism 1, a seed selection and cutting mechanism 2, and a control system. Such as figure 2 As shown, the material handling mechanism 1 includes a first-level vibration material management group 3, a second-level vibration material management group 4, a third-level vibration material management group 5, and a material guide groove group 6 arranged on the first frame A in sequence. . Such as figure 2 As shown, the material guide trough group 6 is composed of a material guide trough 25, and is arranged obliquely downward at the tail of the first frame A. 26 links to each other and corresponds one by one, and its lower end links to each other and corresponds one to one with the selected seed U-shaped groove 22 on the second frame B. The first-stage vibration material management group 3 and the second-stage vibration material managem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com