Automatic control system and automatic control method for multi-wire cutting machine

An automatic control system, multi-wire cutting machine technology, applied in the direction of digital control, electrical program control, manufacturing tools, etc., can solve the problems of single control mode and difficulty in ensuring the stability of control tension, and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

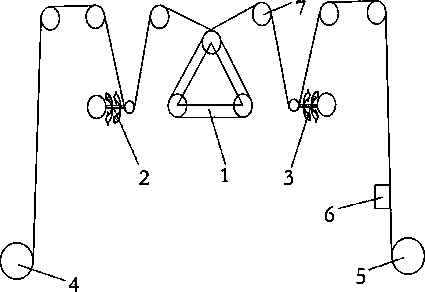

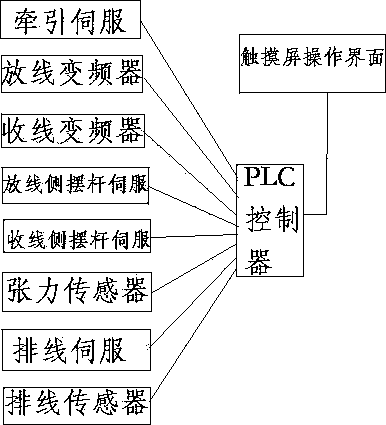

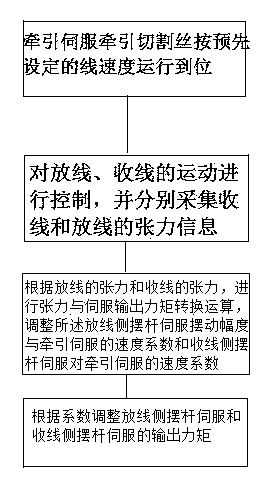

[0033] Such as figure 1 and 2 As shown, the multi-wire cutting machine automatic control system, the system includes:

[0034] The traction servo controls the traction and cutting wire to run to the station of workbench 1 according to the preset linear speed;

[0035] Pay-off frequency converter: control the unwinding motor 4, so that the cutting wire on the I-shaped wheel is placed and run to the workbench 1;

[0036] Winding frequency converter: controls the winding motor 5 to wind the cutting wire;

[0037] Pay-off side swing lever servo: provide the required torque for the pay-off swing lever axis 2, control the tension of the cutting wire, and read the position of the code disc into the PID feedback source of the pay-off inverter;

[0038] Swing lever servo on the take-up side: provide the required torque for the take-up swing lever shaft 3, control ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com