Mems device vacuum packaging structure

A vacuum packaging and device technology, applied in microstructure technology, electric solid device, semiconductor device, etc., can solve the problems of reduced mechanical strength of vacuum packaging of devices, reduced electrical isolation effect of devices, and poor density of through-silicon vias, etc. High density, low contact resistance, good long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

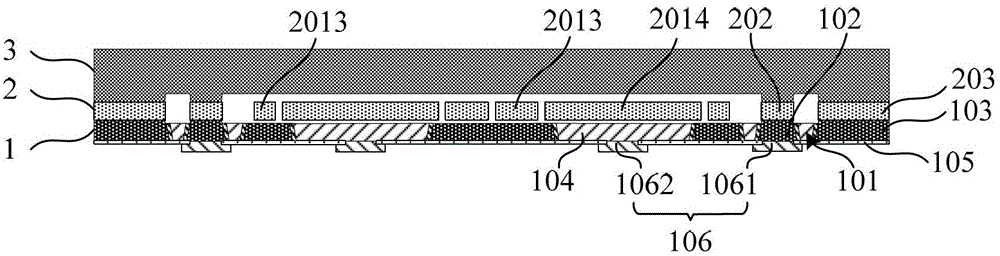

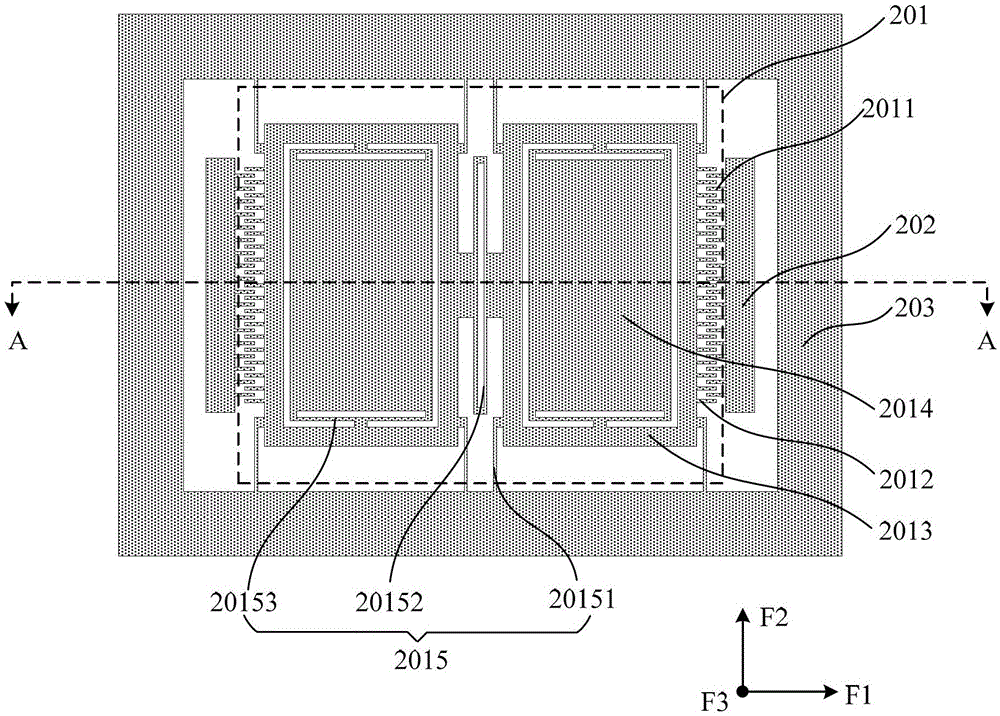

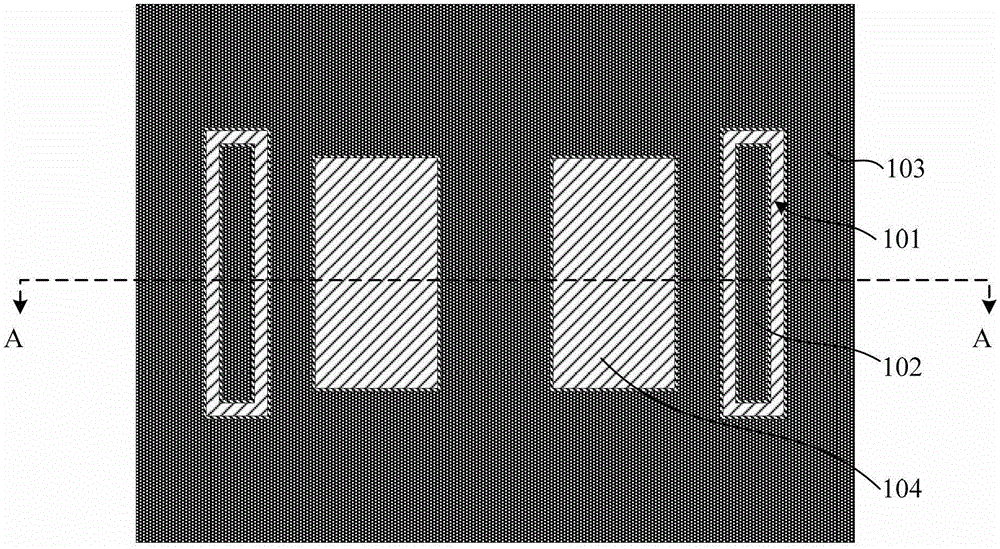

[0076] Such as Figure 1 to Figure 5 As shown, the present invention provides a MEMS device vacuum packaging structure, which at least includes: a substrate 1 , a structural layer 2 , and a cover plate 3 . Wherein, the substrate 1 includes at least an annular isolation structure 101, a first electrode 102, and a frame support structure 103; the structural layer 2 includes at least a frame 203, an electrode connection assembly, and a first region 201 for manufacturing the MEMS device; The cover plate 3 at least includes a first groove 301 . Specifically, in the first embodiment, a micro angular velocity sensor is used as the MEMS device of the structural layer 2 for specific description.

[0077] The structural layer 2 is located on the substrate 1, and at least includes a frame 203 bonded to the inner side of the edge of the substrate 1, an electrode connection assembly of the MEMS device bonded to the first electrode 102, and used to make the The first region 201 of the MEM...

Embodiment 2

[0098] The technical solution of the second embodiment is basically the same as that of the first embodiment, except that the internal structure of the substrate is different. In this second embodiment, only the relevant differences are described, and the same parts as those of the first embodiment are not repeated. A repeat.

[0099] Such as figure 2 , Figure 4 to Figure 7 As shown, the present invention provides a MEMS device vacuum packaging structure, which at least includes: a substrate 1 , a structural layer 2 , and a cover plate 3 . Wherein, the substrate 1 includes at least an annular isolation structure 101, a first electrode 102, and a frame support structure 103; the structural layer 2 includes at least a frame 203, an electrode connection assembly, and a first region 201 for manufacturing the MEMS device; The cover plate 3 at least includes a first groove 301 . Specifically, in the second embodiment, a micro angular velocity sensor is used as the MEMS device o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com