Arsenic removal method based on surface in-situ iron plating technology

An iron-plating and technical technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sewage treatment, etc., can solve problems such as difficulty in engineering practice and application promotion, wide distribution of arsenic and groundwater, and difficulty in identification. , to achieve the effect of cheap treatment method, intact crystal form and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

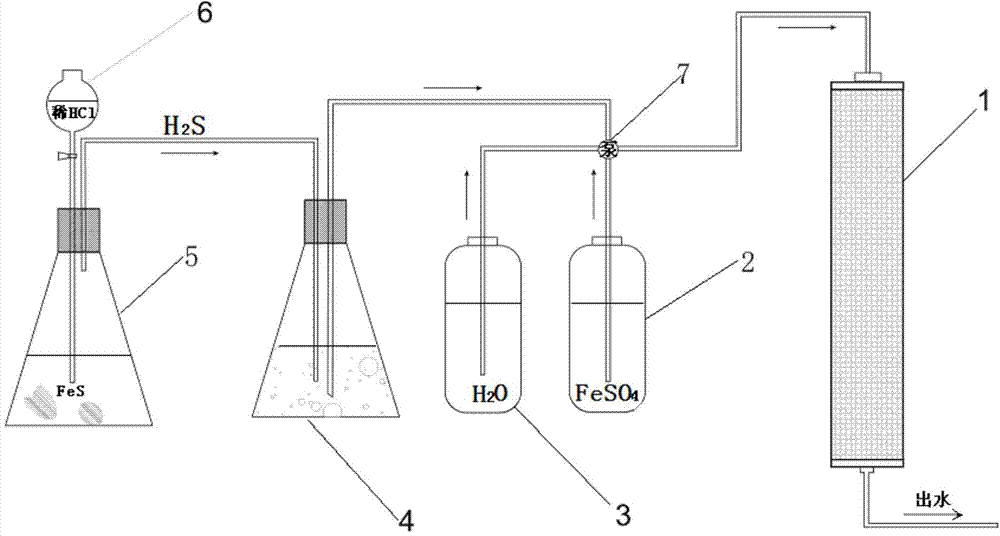

[0019] The arsenic removal device used in this example is as figure 1 As shown, firstly, the cleaned 50-mesh quartz sand and viscous minerals are mixed evenly according to the mass ratio of 9:1, and then filled in a plexiglass column, and the porosity and permeability coefficient of the mixture in the plexiglass column are measured. The inner diameter of the column is 1.4 cm, the height is 30 cm, and the top and bottom of the plexiglass column are respectively provided with a water inlet and a water outlet.

[0020] Then the FeS solid was ground to 100 mesh, mixed with oxygen-free deionized water at a mass ratio of 1:10, configured into a suspension and transferred to H 2 S is generated in the Erlenmeyer flask and sealed with a rubber cork; then configure a dilute hydrochloric acid solution with a mass concentration of 5%, transfer it to a separatory funnel, and then connect the separatory funnel to H 2 S generates Erlenmeyer connection, through to H 2 S is formed by adding ...

Embodiment 2

[0024] In this embodiment, firstly, the washed 50-mesh quartz sand and viscous minerals are mixed evenly according to the mass ratio of 8:2, and the rest of the steps are the same as in Example 1. After the iron plating is completed, the porosity change rate before and after the iron plating is tested. <1%, under the condition of constant water head, the change of permeability coefficient before and after iron plating is <3%. Inject the prepared mixed solution of 500 μg / L Na3AsO4 and Na3AsO3 (1:1 mix) and 5 mg / L NaCl solution into the plexiglass column with a multi-channel peristaltic pump at 3.5 void volume / h. The content of arsenic in the effluent was lower than the detection limit of the atomic fluorescence spectrometer (0.1 μg / L), so the removal rate was greater than 99.99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap