High-purity DHA algae oil ethyl ester and preparation method for transferring high-purity DHA algae oil ethyl ester into glyceride

An oil ethyl ester and ethyl esterification technology, applied in the field of DHA glycerides, can solve the problems of low smoke point of ester products, complicated product process, low DHA percentage content, etc., to improve reaction efficiency and reaction speed, improve DHA content, the effect of increasing the percentage content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

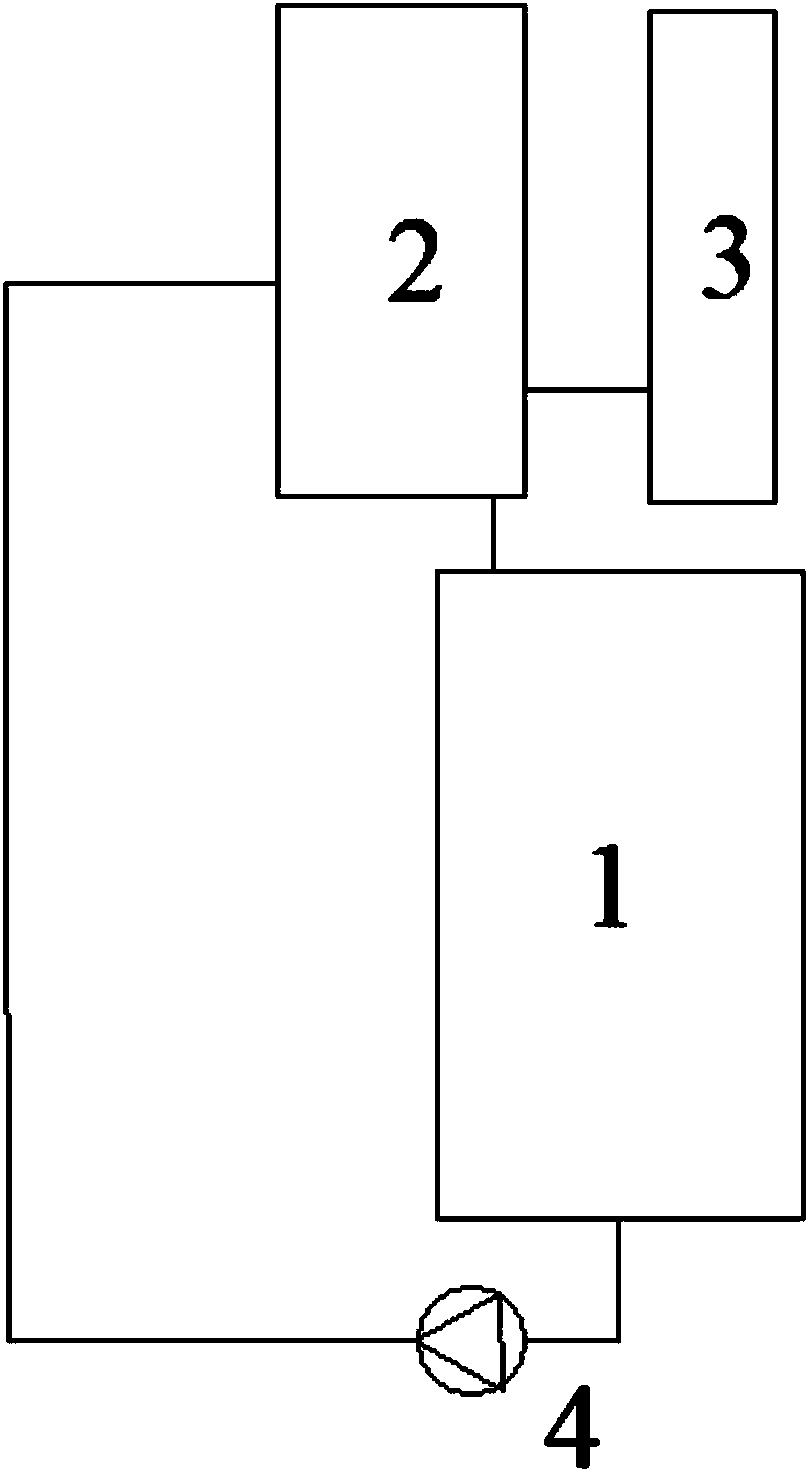

Image

Examples

Embodiment 1

[0029] (1) Ethyl esterification of DHA oil: Dissolve 40g KOH in 1.30kg ethanol, mix 4kg Cryptoninella DHA oil (DHA accounts for 43.48%) and KOH-ethanol solution fully, under the condition of nitrogen filling, Heating and refluxing in a 60°C water bath for 1 hour; cooling to room temperature under nitrogen-filled conditions, standing for stratification, and then taking the upper ethylesterified layer to recover ethanol under reduced pressure distillation at 60°C and -0.1Mpa to obtain the ethylesterified product. Wash with warm water at 40°C until the washing water is neutral, and then rinse with anhydrous Na 2 SO 4 Dry to obtain crude DHA ethyl ester;

[0030] (2) Purification of DHA ethyl ester by secondary molecular distillation method: The crude DHA ethyl ester product enters the molecular distillation device at a feed rate of 5.0g / min through the feed pump for degassing treatment, and the degassing temperature is 70°C, and the heavy components are collected and repeated fo...

Embodiment 2

[0032] (1) Ethyl esterification of DHA oil: Dissolve 32g KOH in 1.45kg ethanol, mix 4kg Crypthecodinium algae DHA oil (43.48% DHA) with KOH-ethanol solution, under the condition of nitrogen Heating and refluxing in a 50°C water bath for 2 hours; cooling to room temperature under nitrogen-filled conditions, standing for stratification, and then taking the upper ethyl esterified layer to recover ethanol under reduced pressure distillation at 60°C and -0.1 Mpa, and the obtained ethyl esterification product was Wash with warm water at 40°C until the washing water is neutral, and then rinsed with anhydrous Na 2 SO 4 Dry to obtain crude DHA ethyl ester;

[0033] (2) Purification of DHA ethyl ester by secondary molecular distillation method: The crude DHA ethyl ester product enters the molecular distillation device at a feed rate of 8.0g / min through the feed pump for degassing treatment, the degassing temperature is 80°C, and the heavy components are collected for repeated distillat...

Embodiment 3

[0035] (1) Ethyl esterification of DHA oil: Dissolve 48g KOH in 1.25kg ethanol, mix 4kg Cryptoninella DHA oil (43.48% DHA) with KOH-ethanol solution, under nitrogen Heating and refluxing in a 70°C water bath for 1 hour; cooling to room temperature under nitrogen-filled conditions, standing for stratification, and then taking the upper ethylesterified layer to recover ethanol under reduced pressure distillation at 60°C and -0.1Mpa. Wash with warm water at 40°C until the washing water is neutral, and then washed with anhydrous Na 2 SO 4 Dry to obtain crude DHA ethyl ester;

[0036] (2) Purification of DHA ethyl ester by secondary molecular distillation method: The crude DHA ethyl ester product enters the molecular distillation device at a feed rate of 20g / min through the feed pump for degassing treatment, the degassing temperature is 80°C, and the heavy components are collected and repeated for distillation 1 The heavy components obtained by degassing were subjected to first-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com