High-purity dha algae oil ethyl ester and its conversion into glyceride preparation method

A technology of oil ethyl ester and ethyl esterification, applied in the field of DHA glycerides, can solve the problems of low smoke point of ester products, complicated product process, low DHA percentage content, etc., to improve reaction efficiency and reaction speed, improve DHA content, the effect of increasing the percentage content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

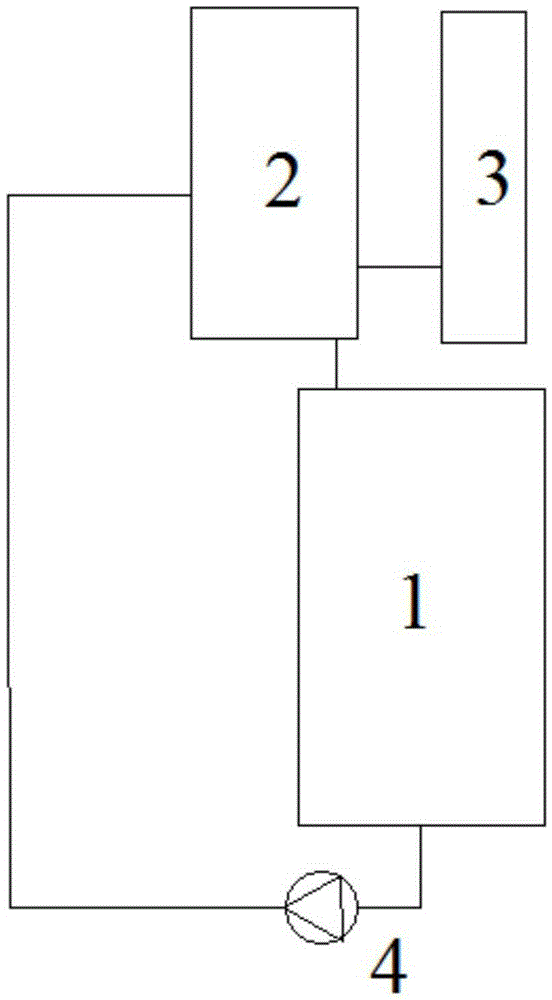

Image

Examples

Embodiment 1

[0029] (1), ethyl esterification of DHA oil: get 40gKOH and be dissolved in 1.30kg ethanol, after fully mixing with KOH-ethanol solution with 4kg cryptodinoflagellate DHA oil (DHA accounts for 43.48%), under the condition of filling nitrogen, in Heating and refluxing in a water bath at 60°C for 1 hour; cooling to room temperature under the condition of nitrogen filling, standing for stratification, taking the upper ethyl esterification layer and distilling under reduced pressure at 60°C and -0.1MPa to recover ethanol, and the ethyl esterification product obtained is Wash with warm water at 40°C until the washing water is neutral, and wash with anhydrous Na 2 SO 4 Dried to obtain the crude product of DHA ethyl ester;

[0030] (2) Purification of DHA ethyl ester by two-stage molecular distillation method: the crude product of DHA ethyl ester enters the molecular distillation device at a feed rate of 5.0g / min through a feed pump for degassing treatment. The degassing temperature...

Embodiment 2

[0032] (1) Ethyl esterification of DHA oil: get 32gKOH and dissolve in 1.45kg ethanol, after fully mixing 4kg cryptodininosaur DHA oil (DHA accounts for 43.48%) and KOH-ethanol solution, under the condition of filling nitrogen, at 50 Heating and refluxing in a water bath at ℃ for 2 hours; cooling to room temperature under the condition of nitrogen filling, standing for stratification, taking the upper ethyl esterification layer and distilling under reduced pressure at 60 °C and -0.1MPa to recover ethanol. ℃ warm water wash until the washing water is neutral, through anhydrous Na 2 SO 4 Dried to obtain the crude product of DHA ethyl ester;

[0033] (2) Purification of DHA ethyl ester by secondary molecular distillation method: the crude product of DHA ethyl ester enters the molecular distillation device through the feed pump at a feed rate of 8.0g / min for degassing treatment. The degassing temperature is 80°C, and the heavy components are collected and distilled 1 time; the h...

Embodiment 3

[0035] (1) Ethyl esterification of DHA oil: get 48gKOH and dissolve in 1.25kg ethanol, after fully mixing 4kg cryptodininosaur DHA oil (DHA accounts for 43.48%) and KOH-ethanol solution, under the condition of filling nitrogen, at 70 Heating and refluxing in a water bath at ℃ for 1 hour; cooling to room temperature under the condition of nitrogen filling, standing for stratification, taking the upper ethyl esterification layer, and distilling under reduced pressure at 60 °C and -0.1MPa to recover ethanol. ℃ warm water wash until the washing water is neutral, through anhydrous Na 2 SO 4 Dried to obtain the crude product of DHA ethyl ester;

[0036] (2) Purification of DHA ethyl ester by secondary molecular distillation method: the crude product of DHA ethyl ester enters the molecular distillation device through the feed pump at a feed rate of 20g / min for degassing treatment, the degassing temperature is 80°C, and the heavy components are collected and distilled repeatedly The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com