Continuous production process of tetraaryl metal porphyrin

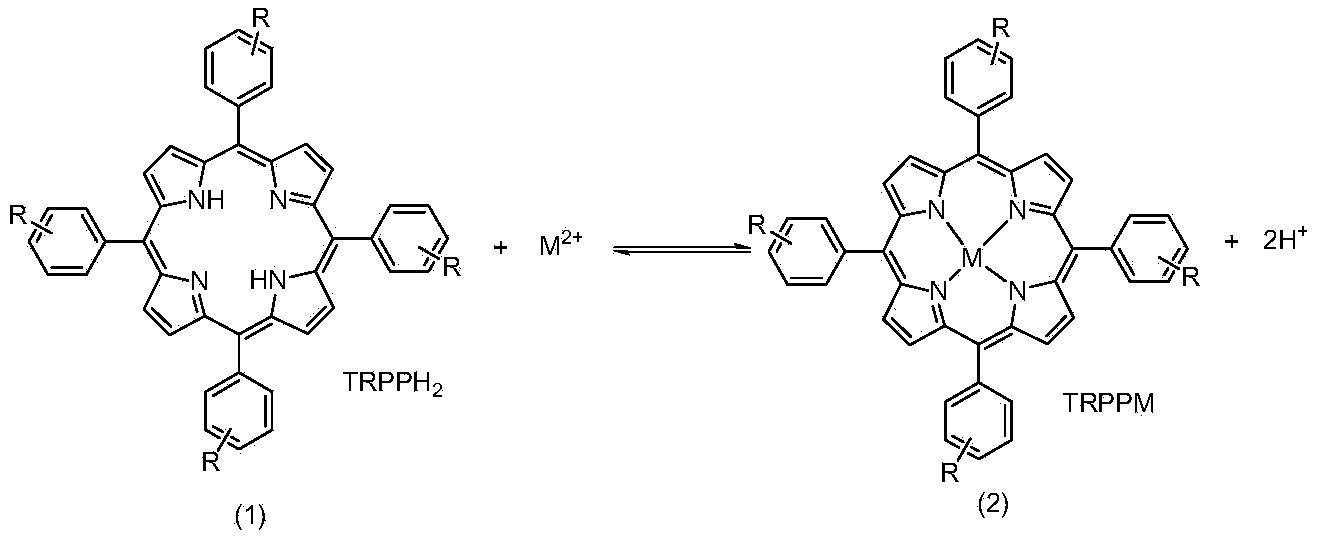

An aryl metal and production process technology, applied in the field of continuous production technology of tetraaryl metalloporphyrin, can solve the problems of poor solubility of tetraaryl metalloporphyrin TRPPM, difficulty in product purification, increase in production cost, etc. Continuous production with high selectivity, avoiding the use of a large amount of solvent, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

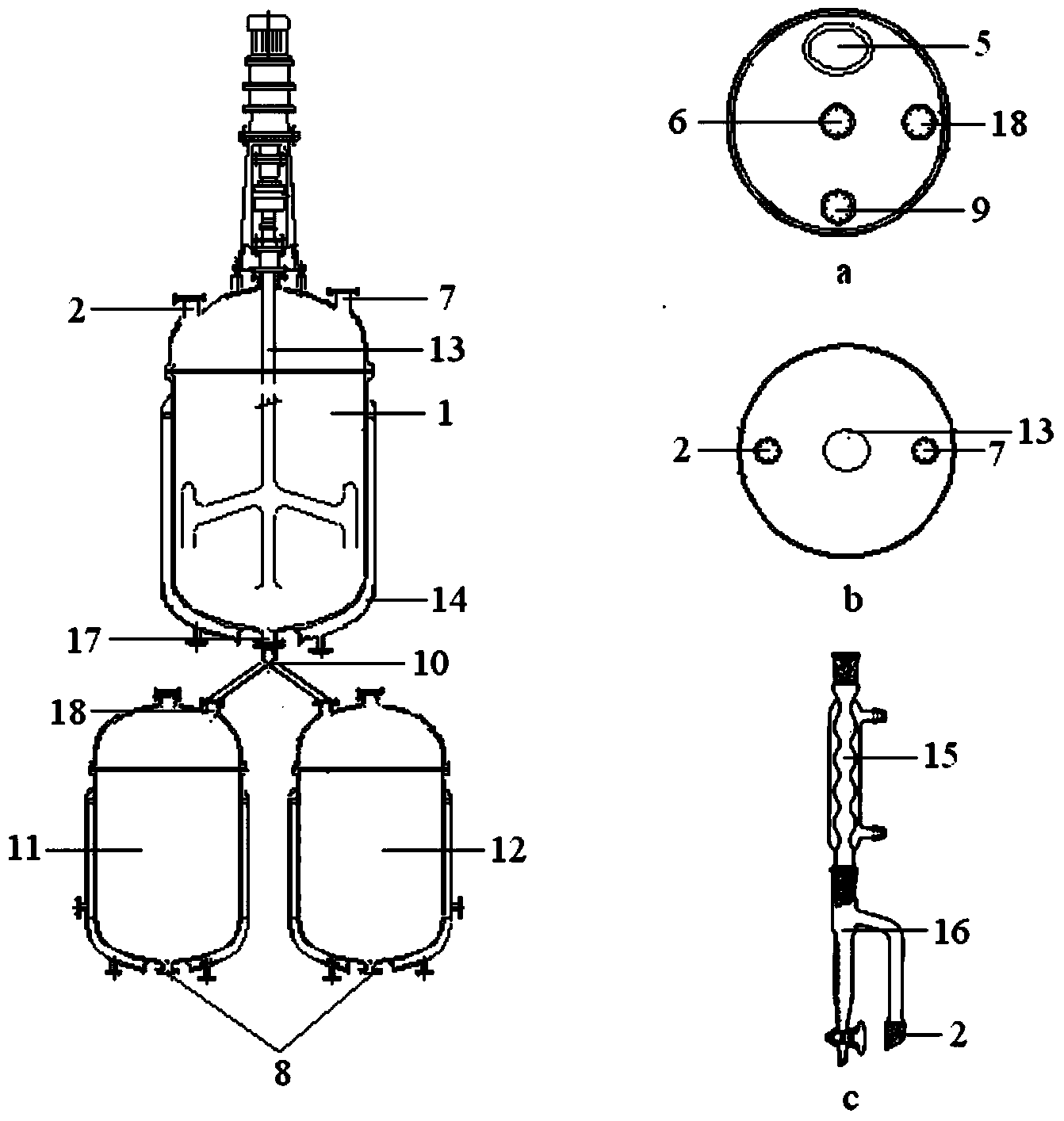

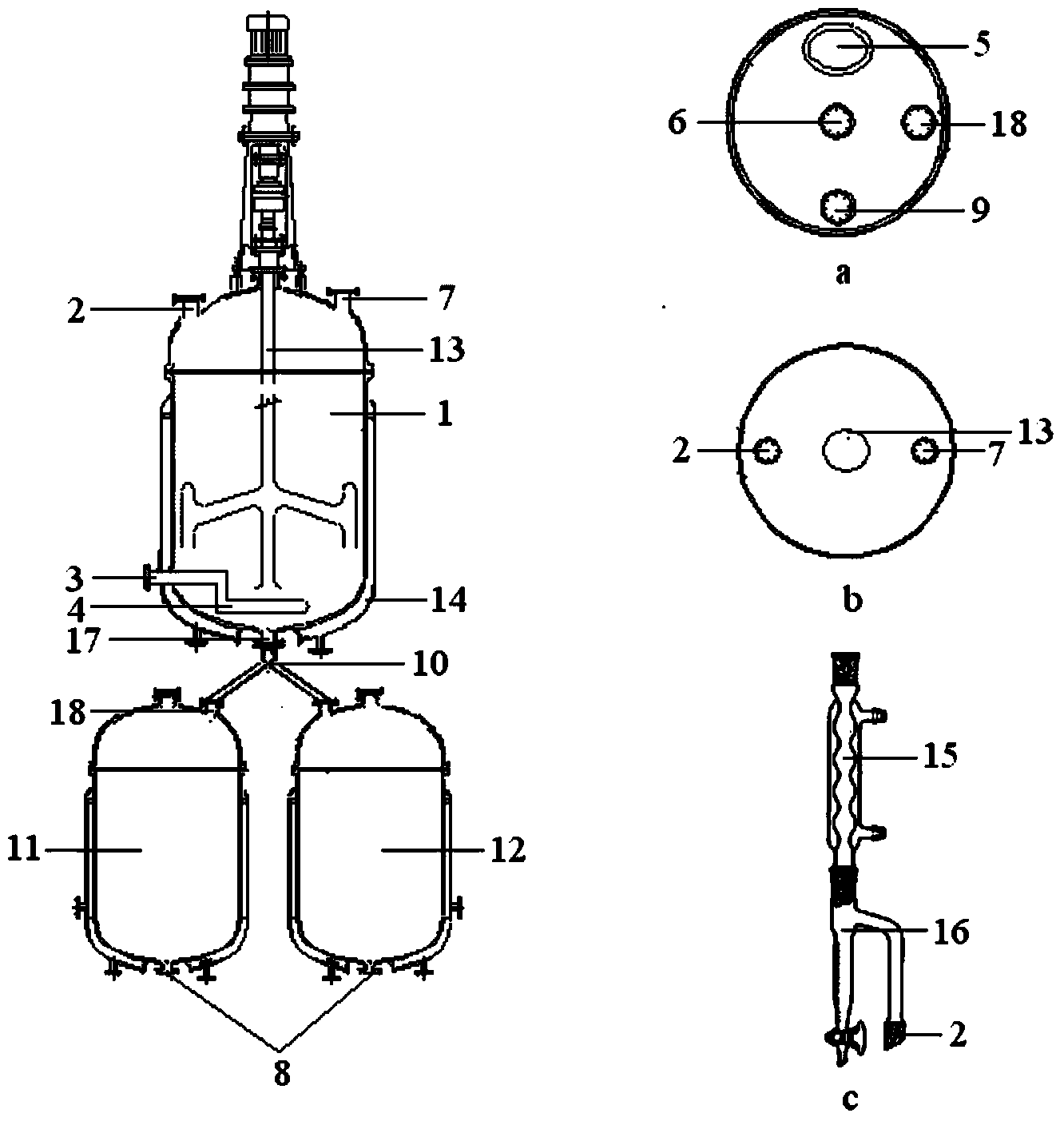

[0046] use figure 1 The shown liquid-solid heterogeneous reaction separation synchronous reactor uses tetra-p-propyl phenyl porphine and cobalt acetate as raw materials for air oxidation to prepare tetra-p-propyl phenyl porphyrin cobalt product; wherein, the diameter-to-height ratio of the stirring reaction tower is It is 1:20; there are two constant temperature settling towers with the same size and structure as constant temperature settling tower I and constant temperature settling tower II; the reaction liquid outlet is 4 / 9 of the height of the tower body from the top of the reaction tower.

[0047] Control the tee under the stirring reaction tower to connect the stirring reaction tower and the constant temperature settling tower I, and add toluene from the solvent inlet at the top of the constant temperature settling tower into the multiphase reaction separation synchronous reactor until the reaction zone and In the constant temperature sedimentation tower I, when the temperat...

Embodiment 2

[0051] use figure 1 The shown liquid-solid heterogeneous reaction separation synchronous reactor uses tetra-p-methoxyphenylporphine and zinc acetate as raw materials for air oxidation to prepare tetra-p-methoxyphenylporphyrin zinc product; among them, the stirring reaction tower diameter The height ratio is 1:20; there are two constant temperature settling towers with the same size and structure as the constant temperature settling tower I and the constant temperature settling tower II; the reaction liquid outlet is 4 / 9 of the height of the tower body from the top of the reaction tower.

[0052] Control the tee under the stirring reaction tower to connect the stirring reaction tower and the constant temperature settling tower I, and add xylene from the solvent inlet on the top of the constant temperature settling tower to the multiphase reaction separation synchronous reactor until the reaction zone of the stirring reaction tower is filled When the temperature is increased to reac...

Embodiment 3

[0056] use figure 1 The shown liquid-solid heterogeneous reaction separation synchronous reactor uses tetra-p-chlorophenyl porphine and nickel acetylacetonate as raw materials for air oxidation to prepare tetra-p-chlorophenyl porphyrin nickel product; wherein the diameter-to-height ratio of the stirring reaction tower is 1:25; There are two constant temperature settling towers with the same size and structure, the constant temperature settling tower I and the constant temperature settling tower II; the reaction liquid outlet is 2 / 5 the height of the tower body from the top of the reaction tower.

[0057] Control the tee under the stirring reaction tower to connect the stirring reaction tower with the constant temperature settling tower I, and add DMF from the solvent inlet on the top of the constant temperature settling tower to the multiphase reaction separation synchronous reactor until the reaction zone and In the constant temperature settling tower I, when the temperature is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com