Triaxial triangular cement mixing drill stem and construction method

A technology of mixing drill pipes and triangles, applied in drilling equipment and methods, drill pipes, drill pipes, etc., can solve the problems of poor anti-tilting ability, endangering life safety, and building toppling, etc., to improve the bearing capacity, increase the The effect of large contact area and enhanced stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

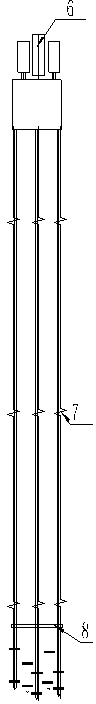

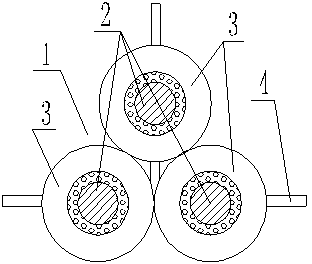

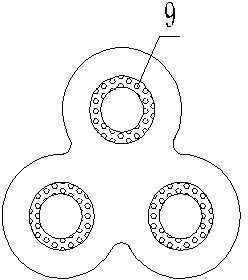

[0012] Embodiment 1: with reference to attached Figure 1 to Figure 4 . A triaxial triangular cement mixing drill rod, comprising a triaxial drill rod 1, each drill rod 2 in the triaxial drill rod 1 is welded with stirring teeth 4; the triaxial drill rod 1 is distributed in a triangle, and the triaxial The heads of the three drill rods in the drill rod 1 are respectively connected to the power output end 6 (such as the three ends of the gear transmission box 3). The included angles between the triaxial drill rods 1 are equal or unequal. (Gear transmission box 3) The power input end is one end or two ends or three ends. When the (gear transmission box) power input end is one end, this end is connected with the power output end of the power mechanism. Each drill shaft in the three-axis drill rod is composed of one or more drill shafts, and the drill shafts are connected by a drill shaft connector 7 . The three-axis drill rods are positioned by one or more three-axis spacing ...

Embodiment 2

[0013] Embodiment 2: On the basis of Embodiment 1, when the (gear transmission box) power input end is two ends, the two ends are respectively connected to the power output ends of the respective power mechanisms. (Gear transmission box) When the power input end is two ends and the power output end is three ends, one end of the power output end is directly driven by a power mechanism through a gear reduction mechanism, and the other two ends of the power output end are driven by another drive mechanism through a gear transmission. The motor turns.

Embodiment 3

[0014] Embodiment 3: On the basis of Embodiment 1, when the (gear transmission box) power input end has three ends, the three ends are respectively connected to the power output ends of the respective power mechanisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com