Test method of fuel cell catalytic layer metal loads

A test method and fuel cell technology, applied in the direction of measuring devices, analyzing materials, and using wave/particle radiation for material analysis, etc., can solve the problems of fast and accurate online monitoring, no catalyst loading, etc., and achieve fast detection and testing The method is simple and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

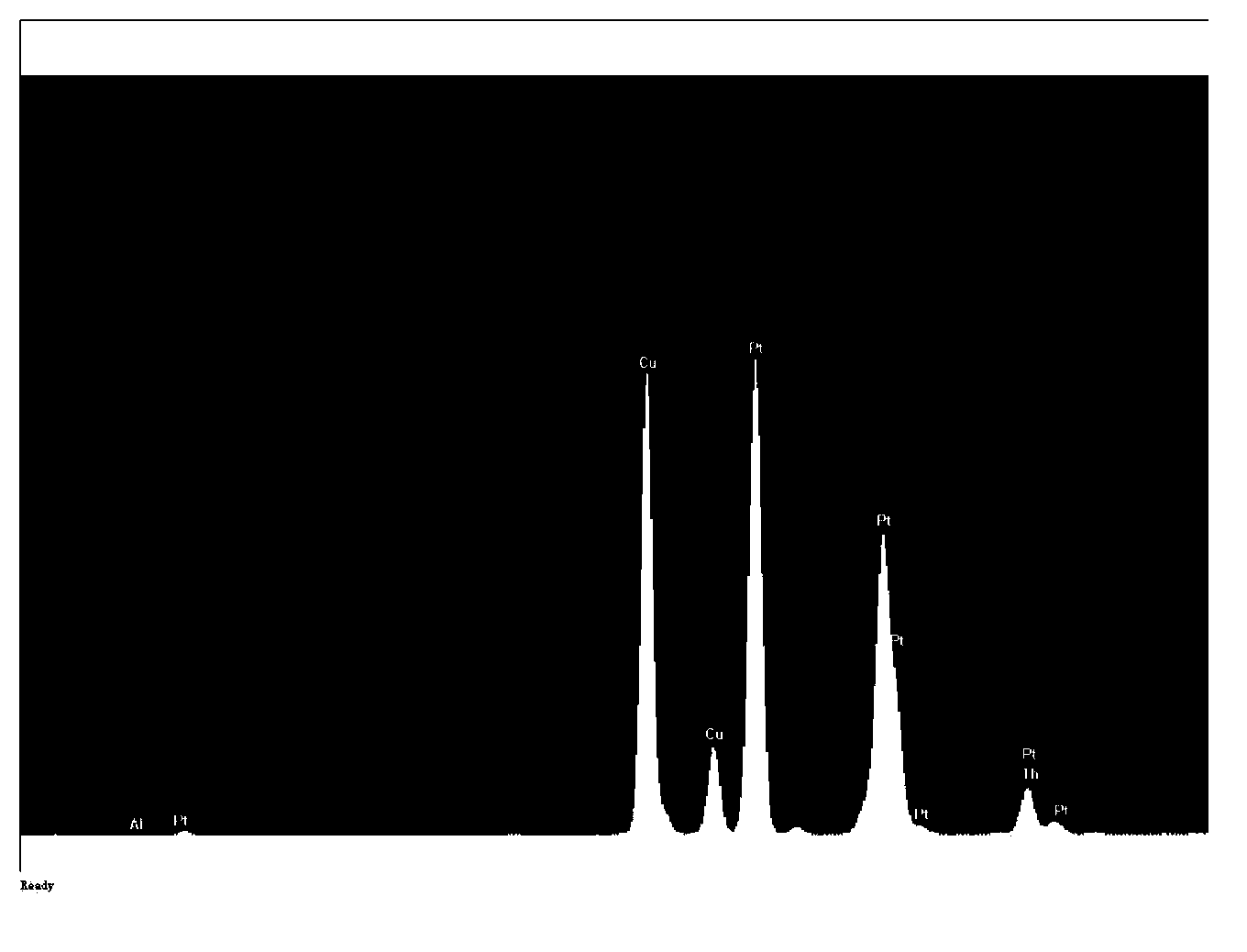

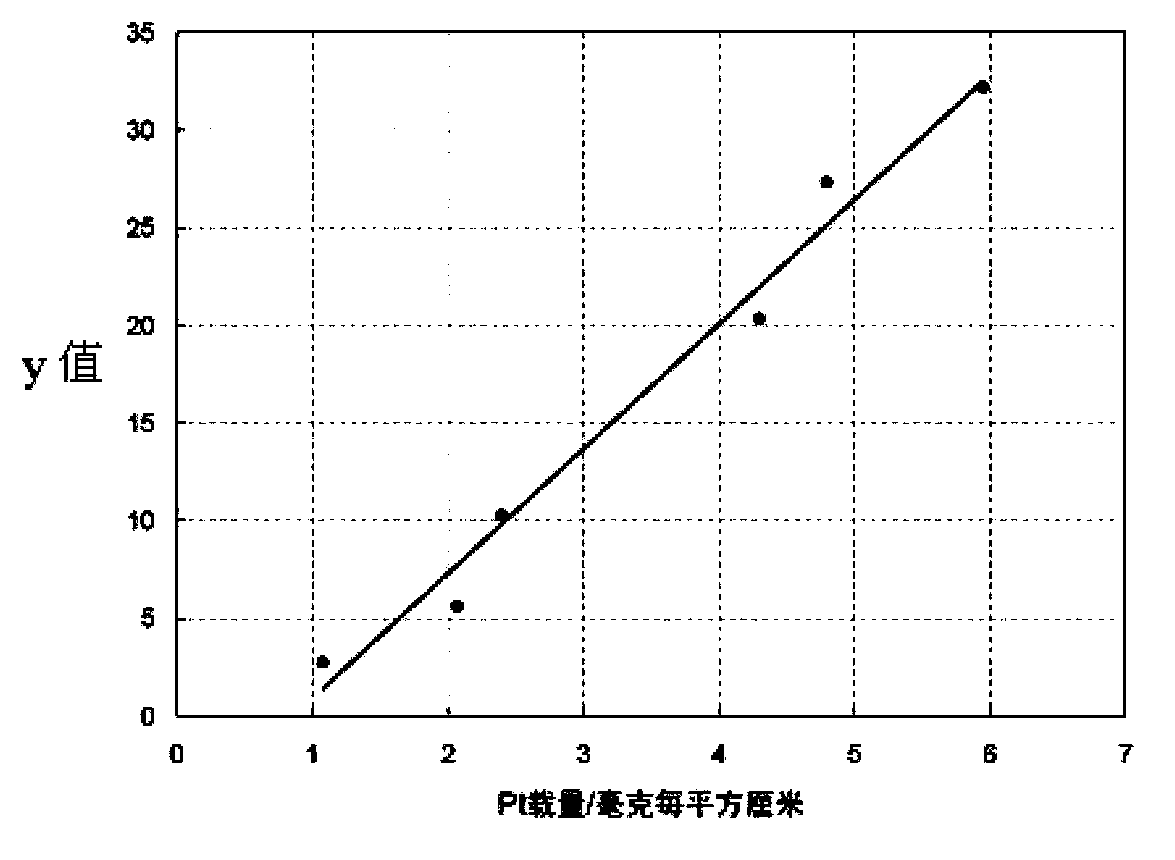

[0039] Example 1: Using ultrasonic automatic spraying method to accurately spray on the PTFE membrane, the loading capacity is: 1, 2, 3, 4, 5, 6 mg / cm 2 The JM60%Pt / C catalyst, the copper foil with a thickness of 50 microns is used as the background sample, and the Pt signal is measured by an X-ray fluorescence spectrometer. The test condition is that the filter material is selected as Pd medium, and the test time is 50 seconds. The ratio of the peak-to-peak strength of 9.44 keV to the peak strength of the background sample copper foil response signal at 8.05 keV is divided by the total number of counts, which is used as the y coordinate and the Pt load as the x coordinate, and the standard curve is drawn.

[0040] The calculation formula fitted by the standard curve is: y=0.22x+0.90

[0041] The Pt load of 60%Pt / C(JM) prepared on the gas diffusion layer by brush coating method is 1.86mg / cm 2 Place the catalytic layer of the cathode downward on the test window of the x-ray fluoresce...

Embodiment 2

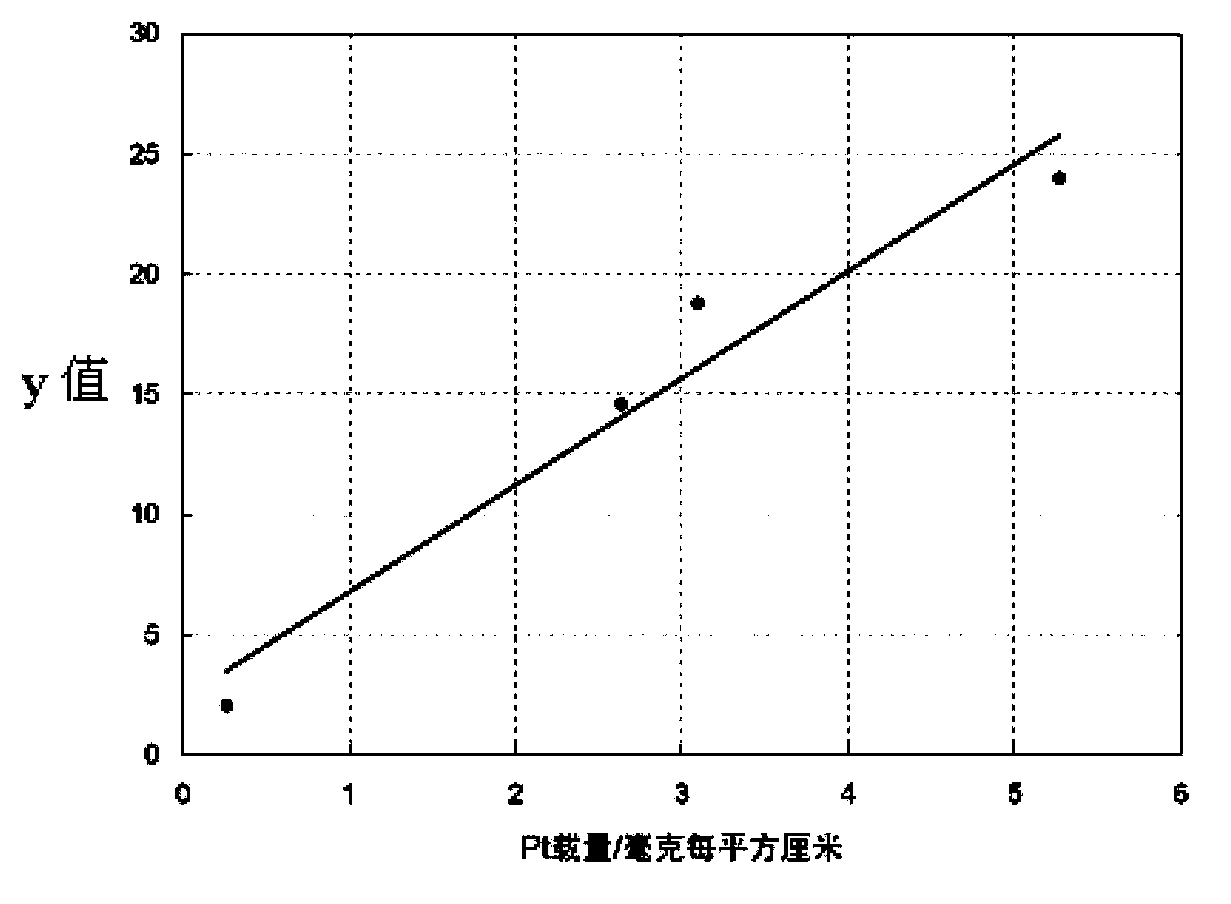

[0042] Example 2: Using ultrasonic automatic spraying method to accurately spray on the PTFE membrane, the loading capacity is: 1, 2, 3, 4, 5, 6 mg / cm 2 The JM60%Pt / C catalyst, the copper foil with a thickness of 50 microns is used as the background sample, and the Pt signal is measured by an X-ray fluorescence spectrometer. The test condition is that the filter material is selected as Pd medium, the test time is 50 seconds, and the Pt response signal The ratio of the peak-to-peak strength of 9.44 keV to the peak strength of the background sample copper foil response signal at 8.05 keV is divided by the total number of counts, which is used as the y coordinate and the Pt load as the x coordinate, and the standard curve is drawn.

[0043] The calculation formula fitted by the standard curve is: y=0.22x+0.90

[0044] The Pt loading of 60%Pt / C(JM) prepared on carbon cloth by brushing method is 1.73mg / cm 2 Place the catalytic layer of the cathode downward on the test window of the x-ray...

Embodiment 3

[0045] Example 3: Using ultrasonic automatic spraying method to accurately spray on the PTFE membrane, the loading capacity is: 1, 2, 3, 4, 5, 6 mg / cm 2 The JM60%Pt / C catalyst, the copper foil with a thickness of 50 microns is used as the background sample, and the Pt signal is measured by an X-ray fluorescence spectrometer. The test condition is that the filter material is selected as Pd medium, and the test time is 50 seconds. The ratio of the peak-to-peak strength of 9.44 keV and the peak strength of the background sample copper foil response signal at 8.05 keV is divided by the total number of counts, which is used as the y coordinate and the Pt load as the x coordinate, and the standard curve is drawn.

[0046] The calculation formula fitted by the standard curve is: y=0.22x+0.90

[0047] Place the cathode catalyst layer with a Pt loading of 4.05mg / cm2 with a Pt loading of 4.05mg / cm2 and 40% Pt / C(JM) prepared by brush coating method on the x-ray fluorescence spectrometer. Plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com