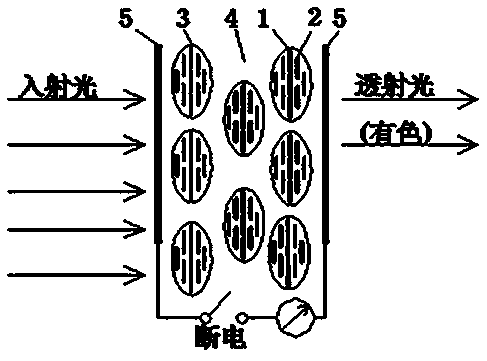

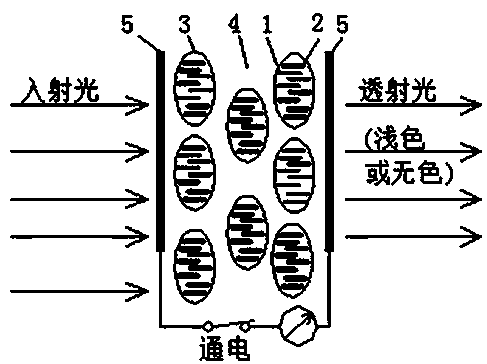

Method for preparing color polymer dispersed liquid crystal films

A technology of dispersed liquid crystal and polymer, applied in optics, instruments, nonlinear optics, etc., can solve the problems of colorful, unable to produce color, etc., and achieve the effect of eliminating visual differences, reducing visual haze, and reducing fog effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of a colored polymer dispersed liquid crystal film, using anthraquinone dyes and azo dyes, the operation steps are as follows:

[0019] A. Mix anthraquinone dyes or azo dyes into liquid crystal raw materials, heat and stir evenly to color the liquid crystal raw materials to form colored liquid crystals; the anthraquinone dyes are 1,5-bis(phenylthio)anthraquinone dyes or 1,5-di(p-alkyl or alkoxy)anilinoanthraquinone dye or 1-(p-alkyl or alkoxy)anilinoanthraquinone dye or 1,5-diamino-4,8- Dihydroxy-2(p-alkoxybenzene)anthraquinone dye or 1,5-diamino-4,8-dihydroxy-3(p-alkoxybenzene)anthraquinone dye or 1,5-diamino- At least one dye or at least three dyes in 4,8-dihydroxy-3,7-bis(p-alkoxybenzene)anthraquinone dyes; azo dyes are p-dimethylaminoazobenzene dyes or bis Azo blue dye (Japanese dye, its product model is G168) or trisazo yellow dye (Japanese dye, its product model is G232); the weight percentage of the dye to the liquid crystal raw material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com