Preparation method of peach-kernel-shaped SnO2-graphene-carbon composite material for lithium ion battery

A technology of lithium-ion batteries and carbon composite materials, applied in the field of materials, can solve problems such as structural damage, shedding, and poor cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

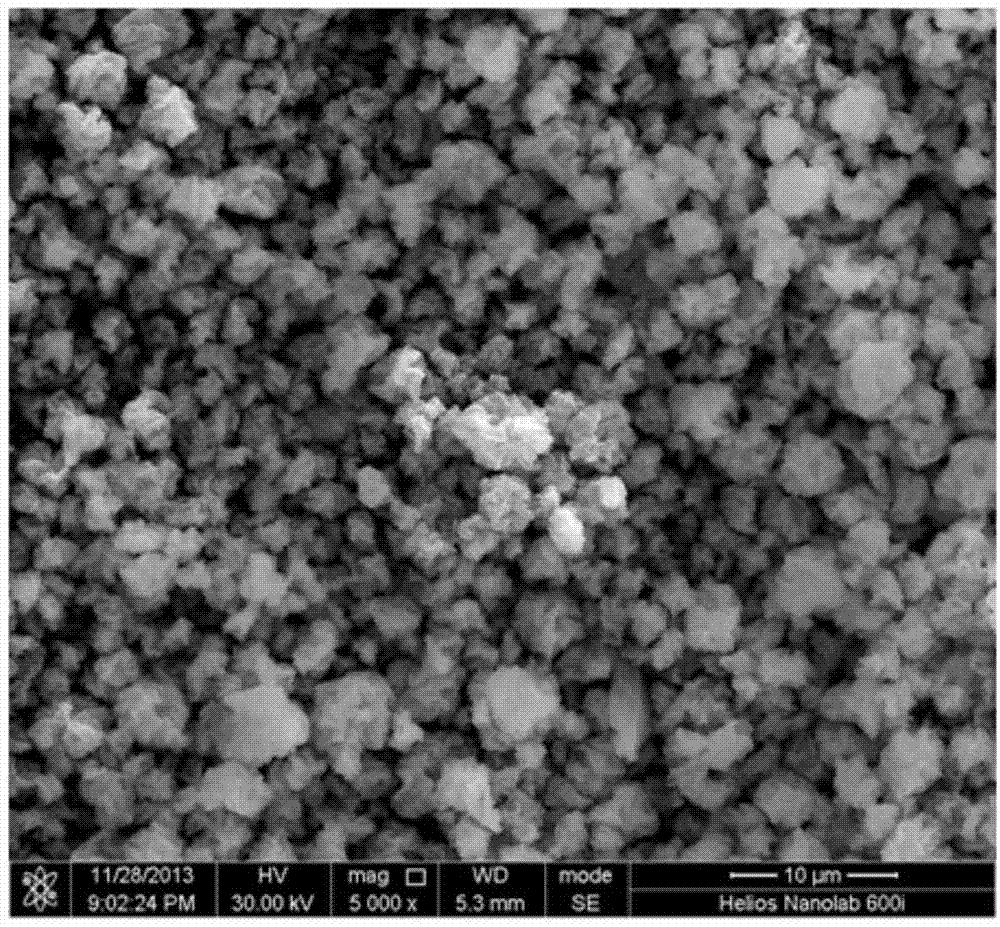

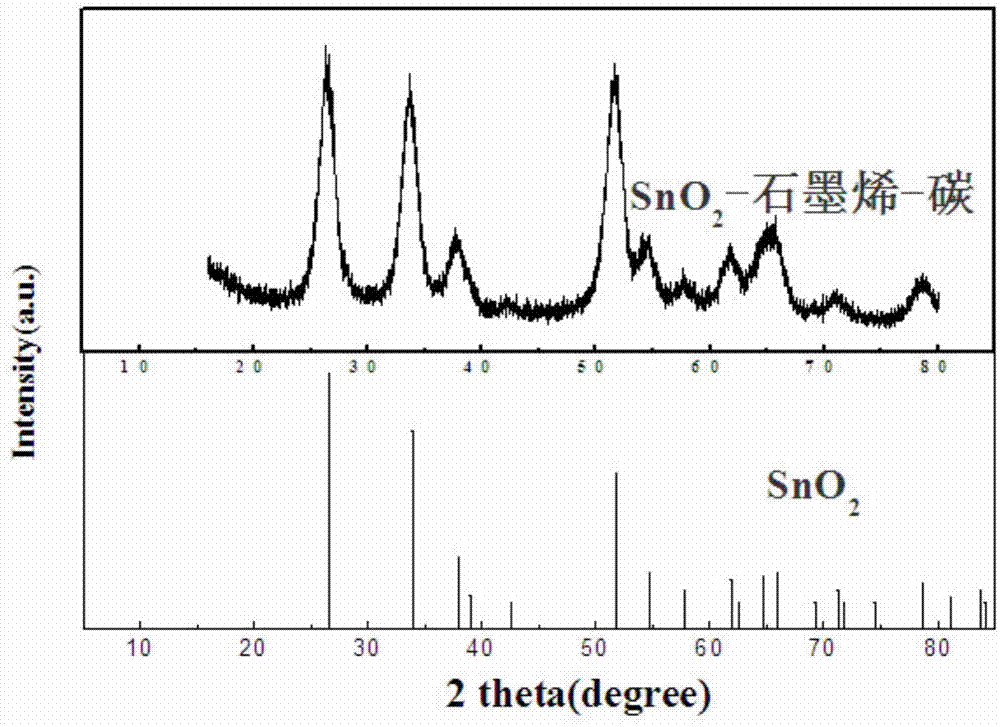

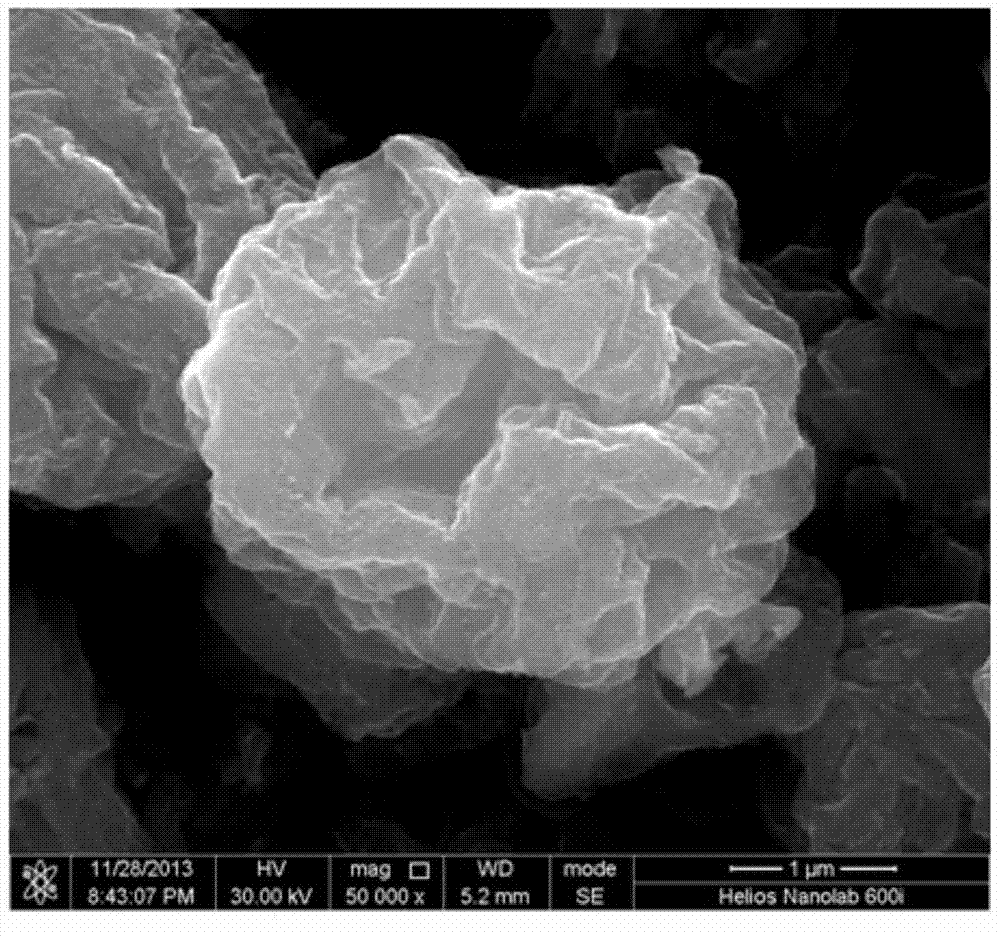

Image

Examples

Embodiment 1

[0026] (1) Mix and stir

[0027] 0.9g graphene oxide and 13.3g tin chloride (SnCl 4 ·5H 2 O) Dissolve in 600mL and 80mL deionized water respectively, sonicate and stir until graphene oxide and SnCl 4 ·5H 2 O is completely dissolved. Afterwards, the above two solutions were mixed together, ultrasonicated and stirred for more than 36 hours.

[0028] (2) spray drying

[0029] The above solution was spray-dried in a spray-drying apparatus, and the experimental parameters were inlet temperature of 180°C, feed rate of 2r / min, and blast pressure of 0.2Mpa. The spray precursor powder material is prepared by spray drying.

[0030] (3) Hydrothermal treatment

[0031] Weigh 1 g of the spray-dried precursor and dissolve it in 80 mL of 0.01 g / mL glucose solution, stir for 6 h, then perform hydrothermal reaction at 180 °C for 5 h, wash with water several times, and dry at 80 °C for 12 h.

[0032] (4) Calcination process

[0033] The collected samples were kept in H 2 / Ar atmospher...

Embodiment 2

[0039] The difference between this embodiment and Example 1 is that the quality of graphene oxide and tin chloride is 00.8g and 23.6g respectively, and they are dissolved in 500ml and 100ml deionized water respectively. After the two are completely dissolved in water, the two are mixed Ultrasonic stirring for more than 48h. When spray drying, set the feed rate to lr / min. During the hydrothermal process, the stirring time of the spray precursor and the glucose solution was set to 10 h. During the calcination process, the composite material was heat-treated at 550° C. for 20 minutes to prepare a carbon-coated peach kernel-shaped tin-based composite material for the negative electrode of lithium-ion batteries.

[0040] Image 6Shown are the cycle and rate performance curves of the composite prepared in Example 2. The composite material has excellent cycle stability at a higher rate, and the composite material still has a high capacity of 650mAh / g at a high current density of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com