Processing method of precision aluminium alloy mold

A processing method and aluminum alloy technology, which is applied in the processing of precision aluminum alloy molds and the field of mold processing, can solve problems such as matching accuracy, difficulty in controlling processing accuracy, and large extrusion ratio, so as to avoid low processing accuracy and high production efficiency. High, operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

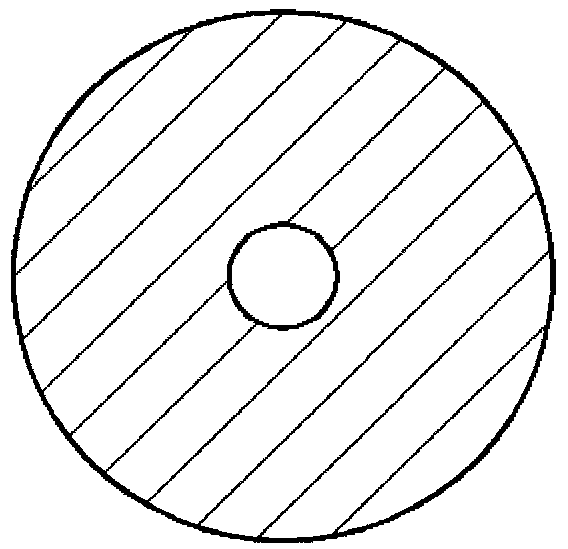

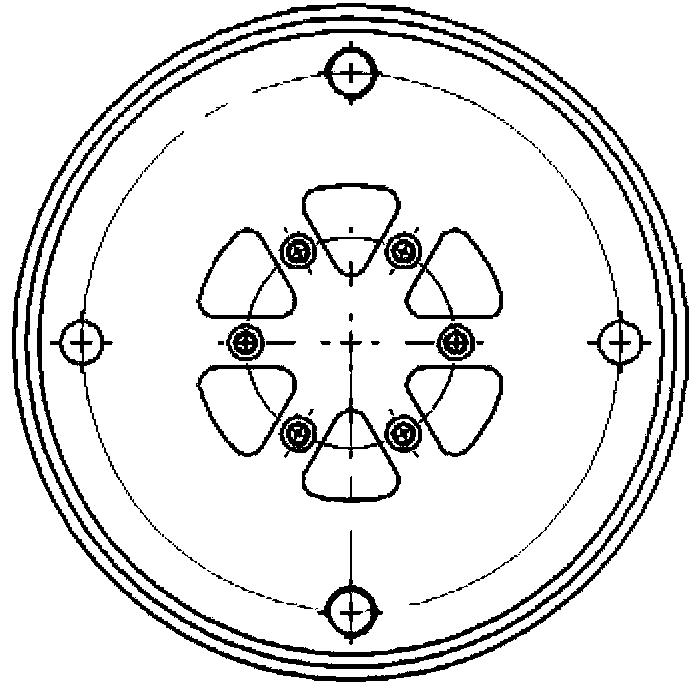

[0028] To process 6063 aluminum alloy thick-walled round tube products, the product structure is as follows figure 1 As shown, the dimensional accuracy requires 0 mm~0.05 mm. This product is formed by hot extrusion with a split-flow combination die. The mold material is H13 steel (4Cr5MoSiV1). The mold structure is designed to be 6 out of one mold (extrusion coefficient is 49.2). The mold structure diagram is shown in Figure 2. The specific processing technology is as follows:

[0029] First of all, select the annealed mold blank for rough machining, including: the processing of the upper mold shape, split hole, screw hole, pin hole, seam, core transition zone, and wire hole; the lower mold welding chamber, empty Processing of knives, pin holes, screw holes, threading holes, etc.;

[0030] Vacuum quenching heat treatment is carried out on the mold blank processed by rough turning. The heat treatment process is as follows: heating to 1020 ℃ ~ 1050 ℃, oil quenching (oil tempera...

Embodiment 2

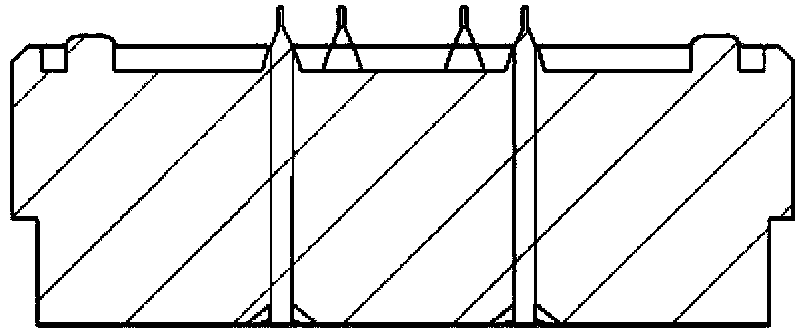

[0036] Want to process 1070 aluminum alloy single-hole channel pipe products, the product structure is as follows image 3 As shown, the mold material is 3Cr2W8V, and the mold structure is designed as a single mold. The mold structure diagram is shown in Figure 4. The specific mold processing technology is as follows:

[0037] First of all, the rough turning process is carried out on the selected mold blank, which mainly includes: the processing of the upper mold split hole, tapping, pin hole, and thread hole; the lower mold screw hole, pin hole, welding chamber, empty knife, and thread hole. Processing of wire holes;

[0038] After the rough turning process is completed, the mold is subjected to vacuum quenching treatment. The specific process is: heating to 1050 ℃ ~ 1100 ℃, after the mold is fully heated, put it into quenching oil at 40 ℃ ~ 60 ℃ for oil quenching, in order to eliminate stress and stabilize the structure and Size, the mold after quenching should be tempered ...

Embodiment 3

[0044] Want to process 6061 aluminum alloy three-hole channel pipe products, the product structure is as follows Figure 5 As shown, the mold material is 3Cr2W8V, and the mold structure is designed as a single mold. The mold structure is shown in Figure 6. The specific processing method is as follows:

[0045] First of all, the selected mold blank is subjected to rough turning processing including the shape, split holes, pins, bolts, process holes, threading holes, etc.; the number of threading holes in the mold core is 3, and the corresponding threading holes of the lower die The number should also be 3;

[0046] Carry out quenching heat treatment to the mold blank after rough machining; Heat treatment process is the same as embodiment 2;

[0047] Complete the processing and matching of the stopper, pins and bolts of the mold after quenching;

[0048] Use slow wire cutting equipment to cut the reference hole of the mated mold. The processing of the reference hole should ens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com