Regulation method for high-dryness dehydration of sludge

A sludge and high dry technology, applied in the field of environmental engineering, can solve the problems of poor dewatering performance, uneven stirring affecting conditioning effect and dewatering effect, etc., and achieve the effects of prolonging service life, good stirring effect and simple addition process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be further described through specific embodiments below in conjunction with the accompanying drawings.

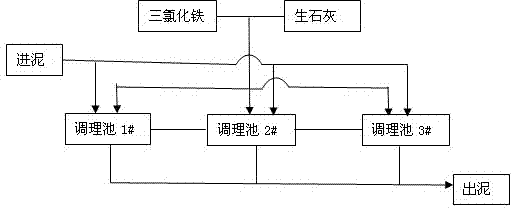

[0014] like figure 1 as shown, figure 1 It is a flow chart of the conditioning system of the present invention.

[0015] This embodiment takes a conditioning pool as an example. The sludge in the sludge digestion tank is fed into the conditioning tank by gravity or a sludge pump. The sludge feeding time is about 30 minutes. The initial liquid level of the conditioning tank is 0m. When the sludge is fed to the liquid level of 1m, the mixer starts to stir. Then continue to feed the mud, and when the liquid level reaches 3.2m, stop feeding the mud, and the mixer is always in the stirring state. Then ferric chloride dosing pump is opened, and starts to add ferric chloride solution, and ferric chloride content is 38% in the solution, and optimum addition is 4% of sludge absolute dry weight, stirs 15min after adding,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com