Epoxy resin as well as preparation method and application thereof

An epoxy resin, unsubstituted technology, applied in the direction of electrical components, circuits, electric solid devices, etc., to achieve good heat resistance and mechanical properties, good operability, and easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] Examples are given below to describe the present invention concretely, but the present invention is not limited to these Examples. In addition, the evaluation method in this invention is shown below.

[0102] (1) Melt viscosity at 150° C.: The melt viscosities of the phenol novolak resin and the epoxy resin at 150° C. were measured using an ICI melt viscometer. The measuring method of ICI viscosity is as follows.

[0103] ICI Cone and Plate Viscometer MODEL CV-1S TOA Industry Co., Ltd.

[0104] The plate temperature of the ICI viscometer was set to 150° C., and a predetermined amount of sample was weighed.

[0105] The weighed resin was placed on the plate, pressed with a cone from above, and left to stand for 90 seconds. Spin the cone and read this torque value as the ICI viscosity.

[0106] (2) Hydroxyl equivalent: measured by the method based on JISK0070.

[0107] (3) Epoxy equivalent: measured by a method based on JIS K-7236.

[0108] (4) Dihydric phenol intro...

Synthetic example 1

[0132] 141g (1.5 mol) of phenol, 165g (1.5 mol) of resorcinol, 188.3g (0.75 mol) of 4,4'-bis (Chloromethyl)biphenyl (hereinafter abbreviated as 4,4'-BCMB.) was reacted at 100°C for 3 hours.

[0133] Then, the temperature was raised to 160°C to completely react 4,4'-BCMB. During this time, the generated HCl was distilled off. After completion of the reaction, unreacted phenol and unreacted resorcin were distilled off by vacuum distillation to obtain 250 g of phenol novolak resin.

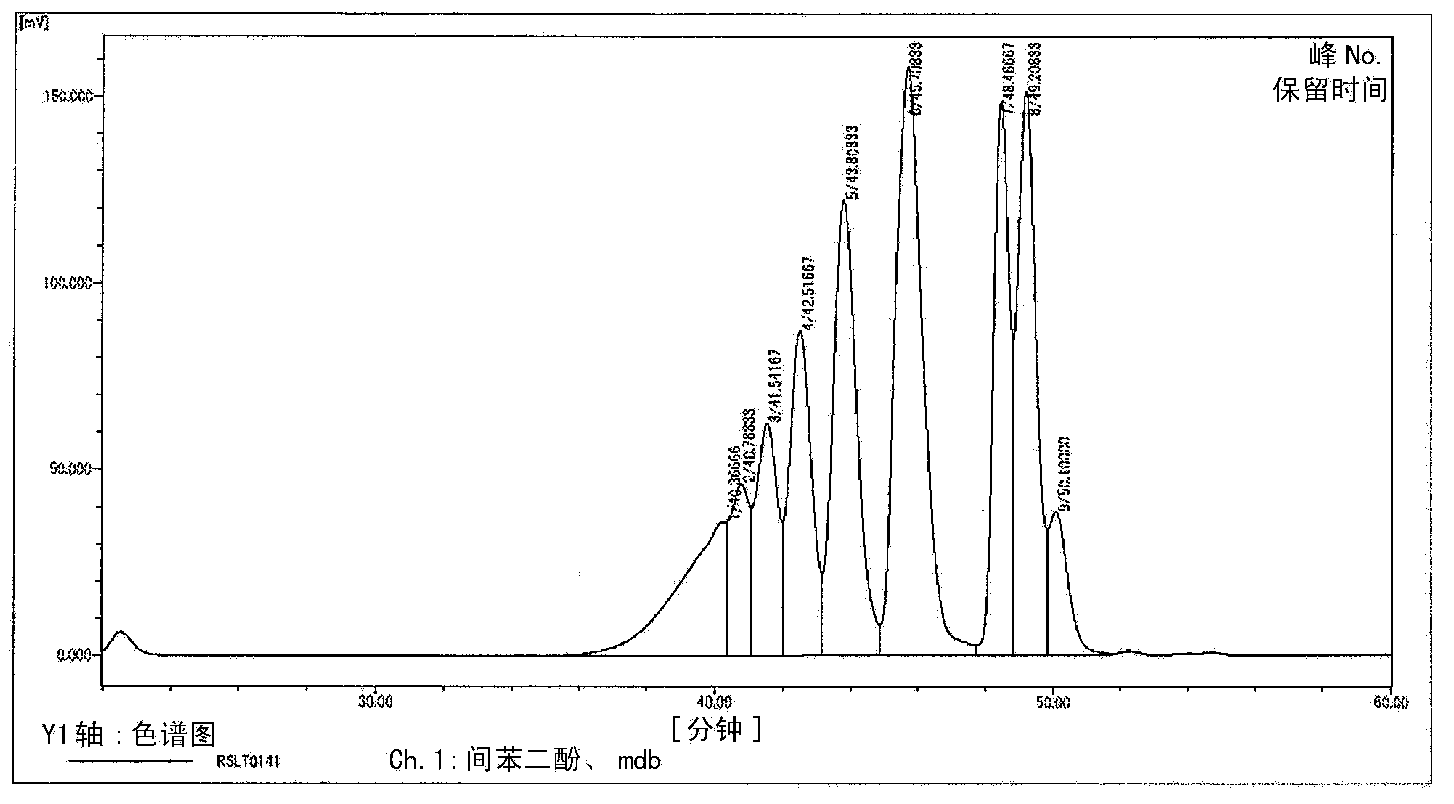

[0134] The obtained phenol novolak resin had an ICI viscosity of 4000 mPa·s and a hydroxyl equivalent of 128 g / eq. The value of n in the general formula (3) was 1.9 (average value: the same below). The GPC chromatogram of the obtained phenol novolac resin is as follows Picture 1-1 shown.

[0135] According to GPC at the end of the reaction, the ratio of monohydric phenol in unreacted phenols was 66%, and the ratio of dihydric phenol was 34%. In addition, the number of moles of unreacted phenols...

Synthetic example 2

[0137] 225.6g (2.4 mol) of phenol, 264g (2.4 mol) of resorcinol, 200.8g (0.8 mol) of 4,4'- BCMB, react at 100°C for 3 hours.

[0138] Then, the temperature was raised to 160°C to completely react 4,4'-BCMB. During this time, the generated HCl was distilled off. After completion of the reaction, unreacted phenol and unreacted resorcinol were distilled off by vacuum distillation to obtain 274 g of phenol novolac resin.

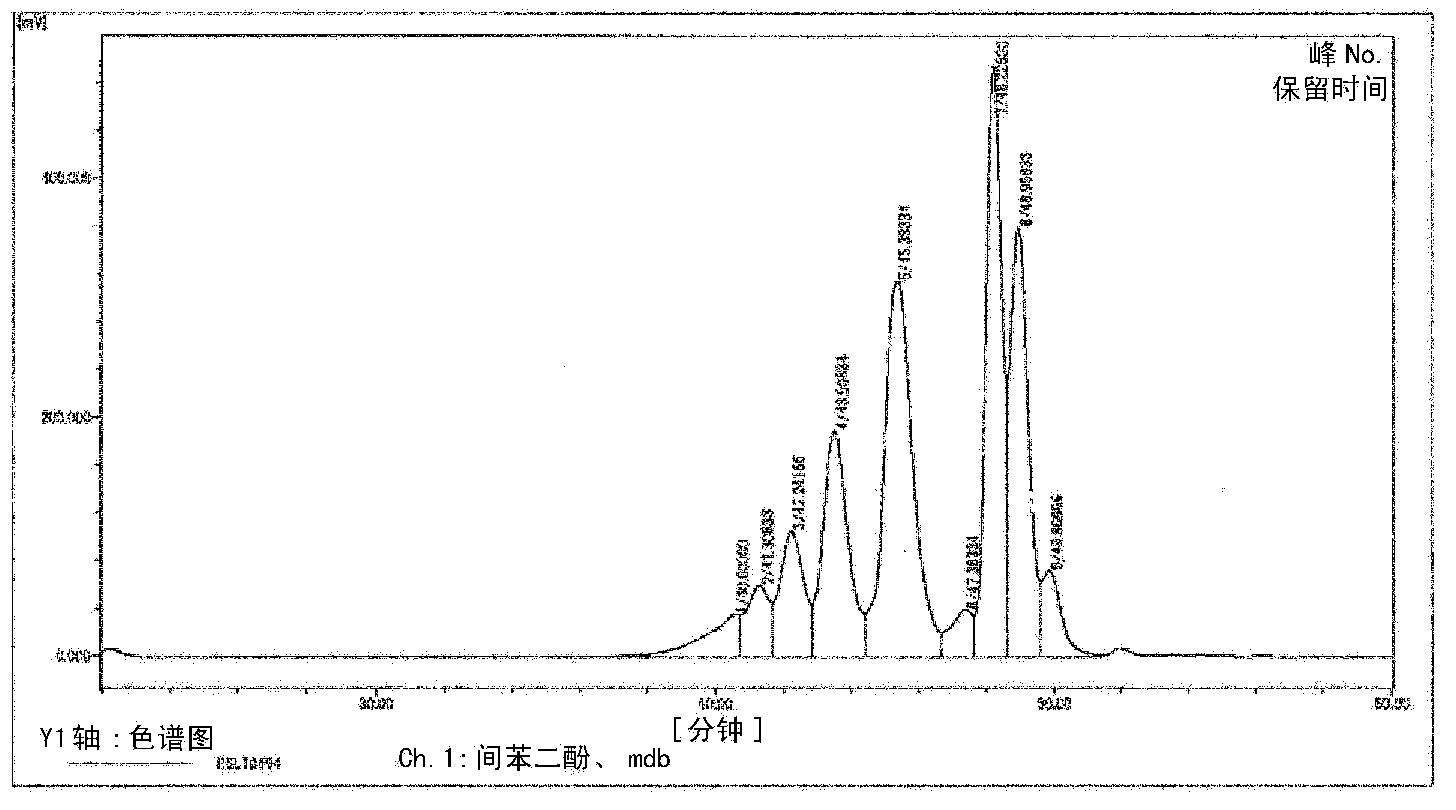

[0139] The obtained phenol novolac resin had an ICI viscosity of 840 mPa·s and a hydroxyl equivalent of 117 g / eq. The value of n in the general formula (3) is 1.1. The ratio of dihydric phenol introduced by GPC calculated in the same manner as in Synthesis Example 1 was 71%. The GPC chromatogram of the obtained phenol novolac resin is as follows Figure 1-2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Hydroxyl equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com