Flame-retardant chain-extending nylon 6 composition and preparation method thereof

A technology of composition and nylon, which is applied in the field of polymer material modification, can solve problems such as uneven dispersion, large amount of composite flame retardants, and decreased tensile strength of flame retardant materials, so as to increase the molecular weight and improve the mechanical properties of materials , good flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

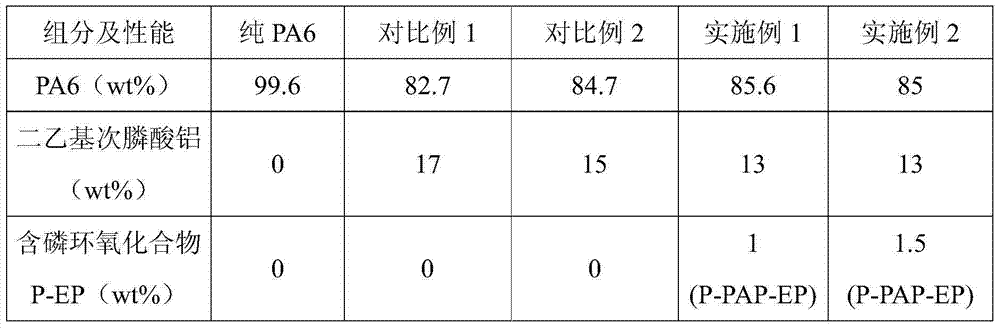

Embodiment 1

[0024] The total amount of control is 1000g, according to mass percentage (recorded as wt%), 85.6wt% PA6, 13wt% aluminum diethylphosphinate, 1wt% P-PAP-EP, 0.3wt% antioxidant B225 and 0.1wt% % Stearic acid is added to a high-speed mixer, stirred and mixed evenly at room temperature, melted, kneaded, extruded, cooled, pelletized and dried by a twin-screw extruder to obtain flame-retardant chain-extended nylon 6 composition pellets. The model of the twin-screw extruder used is LTE26 / 40 (LabTech, Germany). The temperature of each zone of the screw barrel is the first zone: 180°C, the second zone: 235°C, the third zone: 240°C, and the fourth zone: 240°C, the fifth zone: 240°C, the sixth zone: 240°C, the seventh zone: 240°C, the eighth zone: 240°C, the ninth zone: 240°C, the head: 245°C, the feeding speed is 25r / min, the host speed is 180r / min.

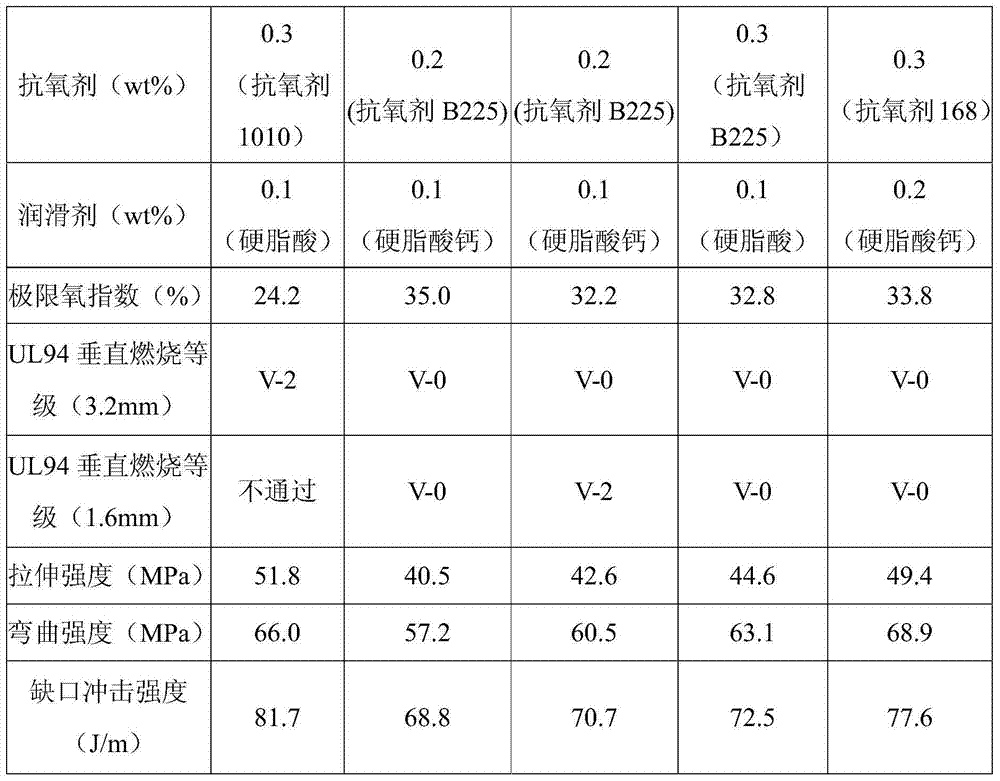

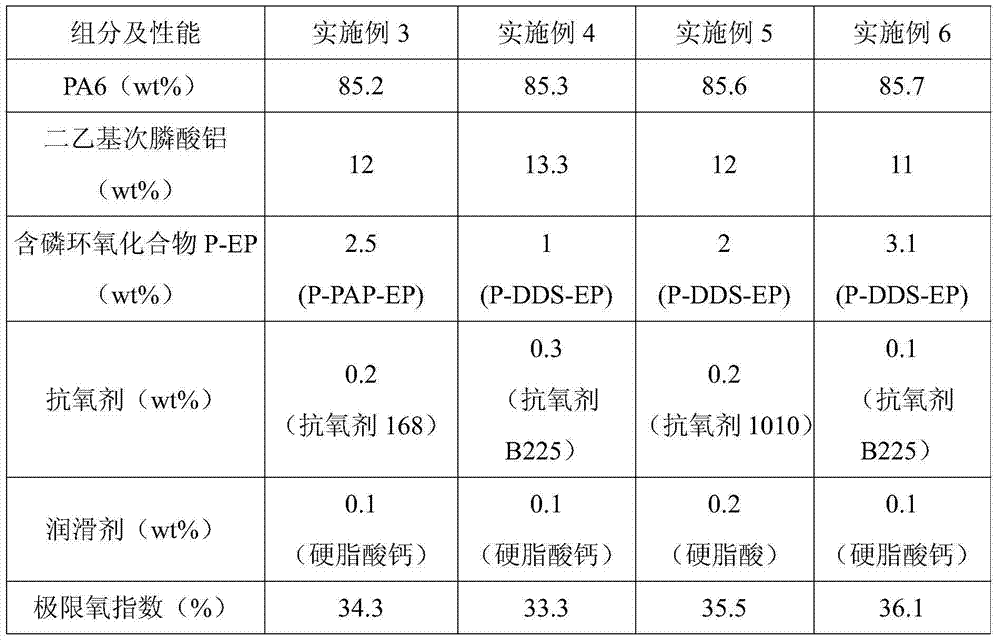

[0025] The ratio of each raw material was changed, and the flame-retardant chain-extended nylon 6 composition pellets of Examples 2-6 o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com