Composite shape memory alloy damper

A technology of memory alloy and memory alloy wire, which is applied in the field of dampers, can solve the problems of no hysteresis energy consumption and low utilization rate of shape memory alloy, and achieve improved shock isolation effect, small space occupation, convenient and flexible use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in more detail below in conjunction with accompanying drawing example:

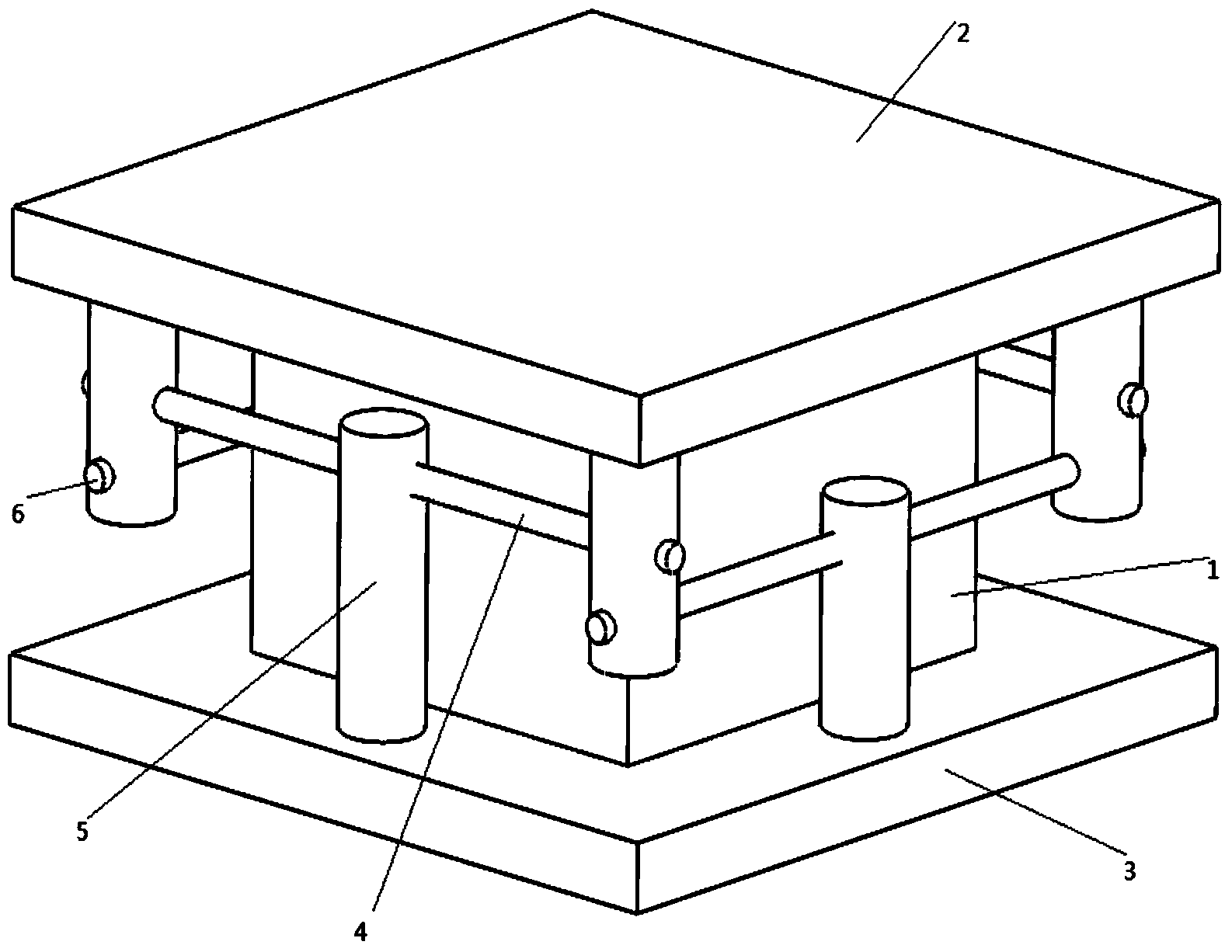

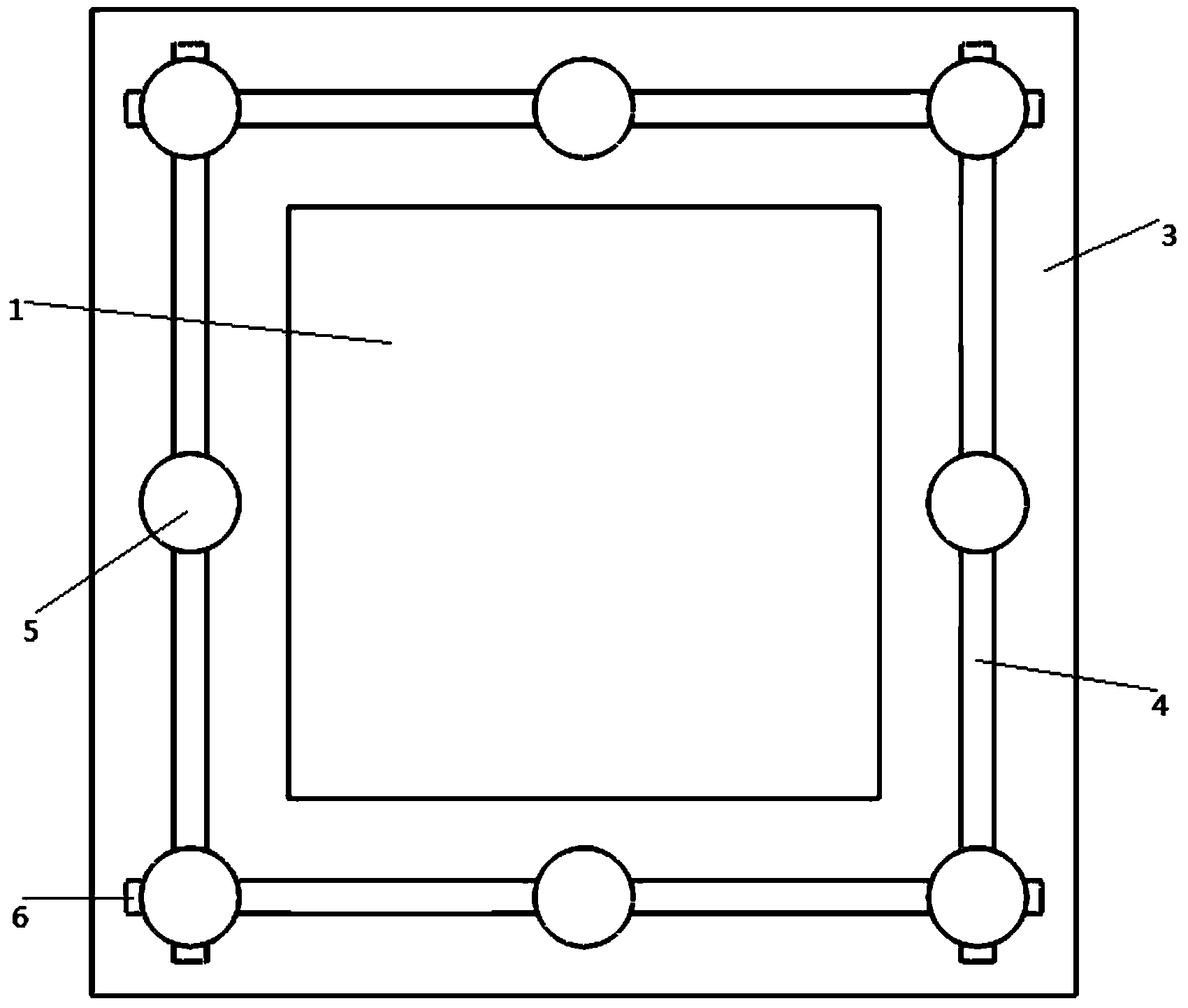

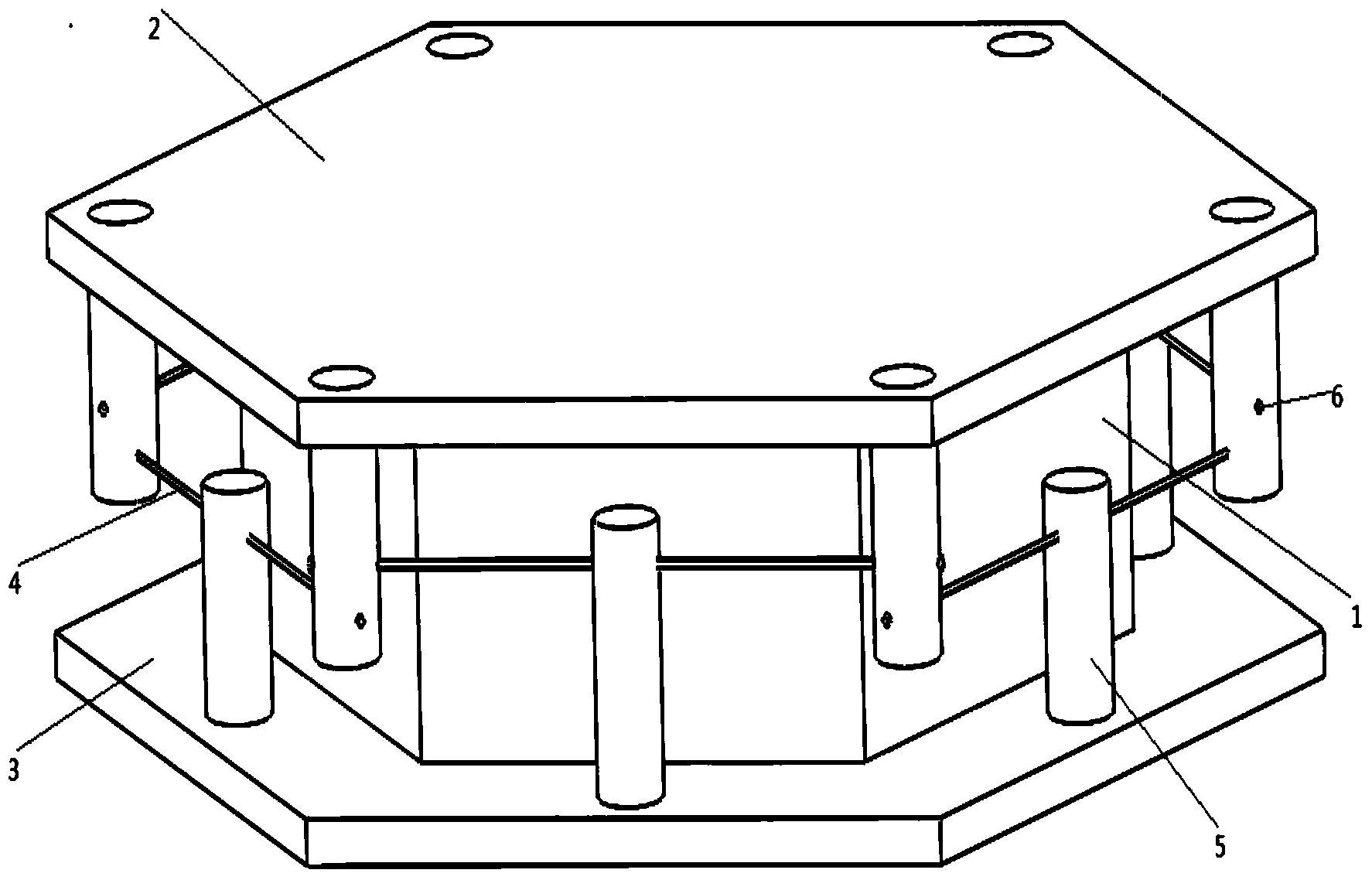

[0025] combine figure 1 ~7. The present invention relates to a composite shape memory alloy damper composed of a core energy dissipation element 1, an upper connecting steel plate 2, a lower connecting steel plate 3, a shape memory alloy wire bundle 4, a steel column with holes 5, and a clamp 6. The upper connecting steel plate 2 and The core energy-dissipating element 1 is fixed in the middle of the lower connecting steel plate 3, and the core energy-dissipating element 1 is a rubber vibration isolation pad. Four perforated steel columns are respectively fixed on the four vertices of the upper connecting steel plate 2 and the midpoints of the four sides of the lower connecting steel plate 3, four groups The shape memory alloy wire bundle 4 passes through the perforated steel column 5 and wraps around the core energy-dissipating element 1 , and the two ends are ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com