An oil filter device and its rotating collision oil filter structure

An oil filter and filter plate technology, which is applied in the fields of oil fume removal, household heating, heating methods, etc., can solve the problems of increasing the difficulty of daily maintenance of the range hood, the limited efficiency of filtering oil fume, and increasing the air inlet resistance, so as to improve the separation effect of oil fume. , convenient for daily maintenance, and the effect of reducing grease residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

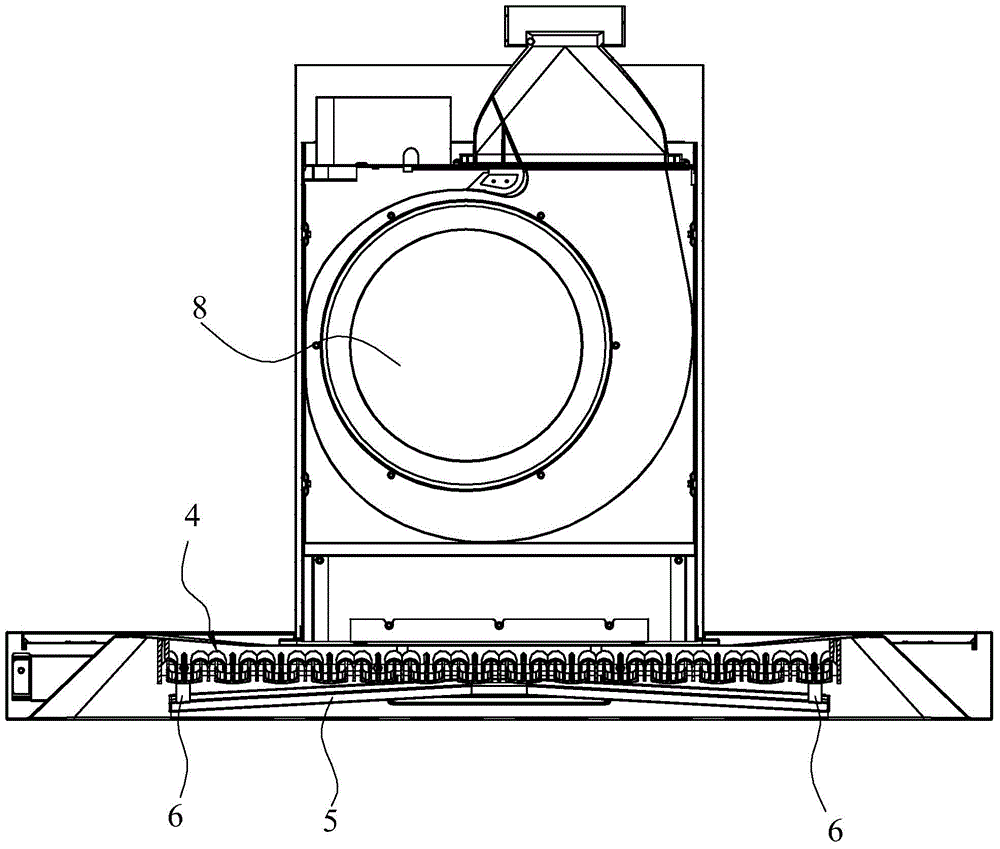

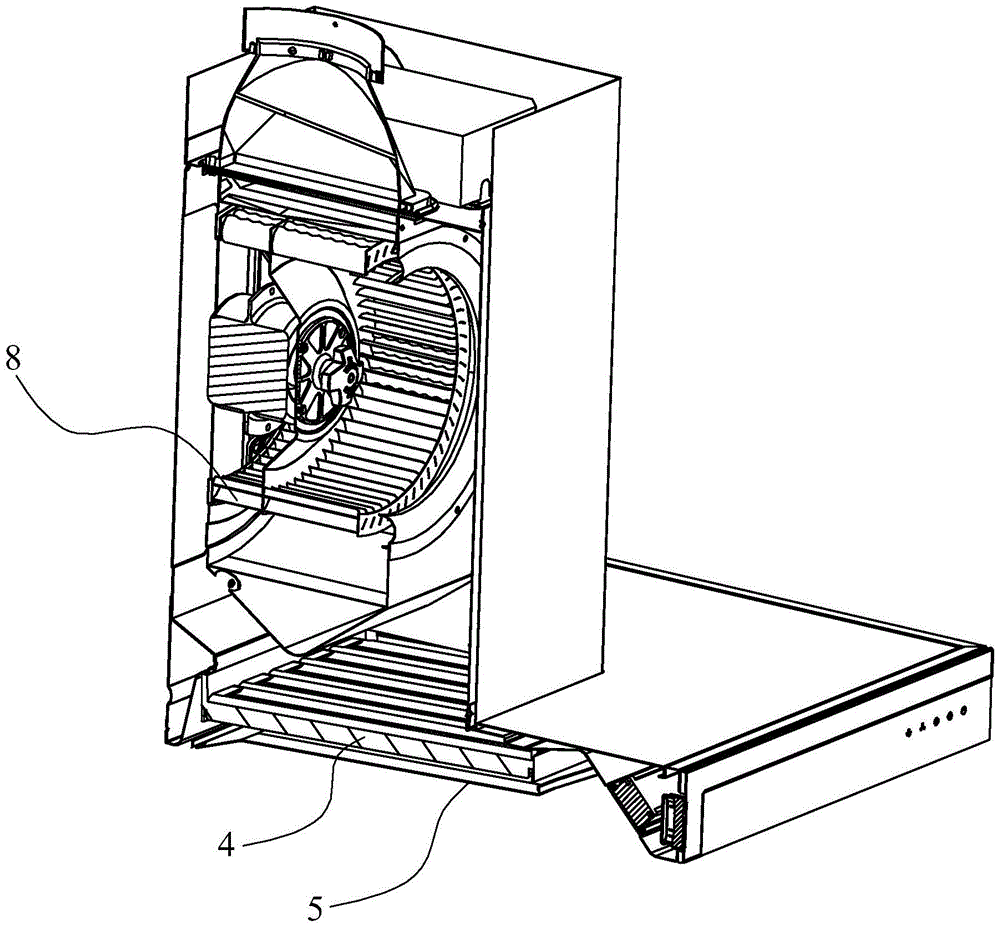

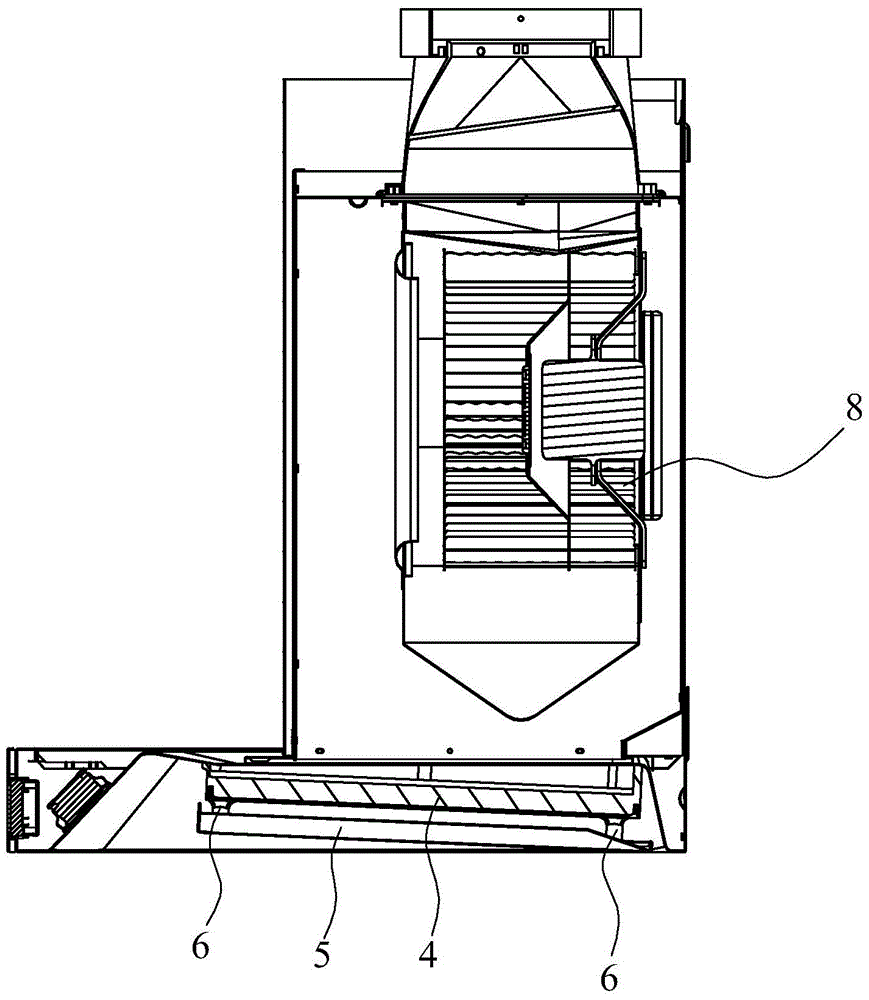

[0035] like Figure 1~3 Shown is a range hood equipped with a fume filter device. The fume filter device 4 is arranged at the air intake of the range hood, and includes a frame 3 disposed on the outer periphery and a rotating collision oil filtering structure disposed inside the frame 3 . Below the oil fume filtering device 4 , ie toward the outside of the range hood, there is an air deflector 5 facing the rotating collision oil filtering structure, and an oil collecting cup (not shown) is arranged at the lower end of the air deflector 5 .

[0036] like Figure 4~7 As shown, the rotary collision oil filter structure includes a plurality of rotary collision oil filter units arranged side by side. In this embodiment, the rotary collision oil filter units are arranged horizontally to form a layered rotary collision oil filter structure. Each rotary collision oil filter unit includes an upper filter plate 1 and a lower filter plate 2 that are upside down and upside down, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com