Stripping construction method of open-pit coal mining in plateau area

An open-pit coal mine and construction method technology, which is applied in the mining of open-pit mines, earthwork drilling, special mining, etc., can solve the deterioration of the formation and discharge conditions of drill cuttings, affect the progress of coal mining construction, and block the formation and discharge of drill cuttings, etc. problems, to achieve the effect of improving blasting efficiency, shortening construction period, and controlling blasting shock waves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

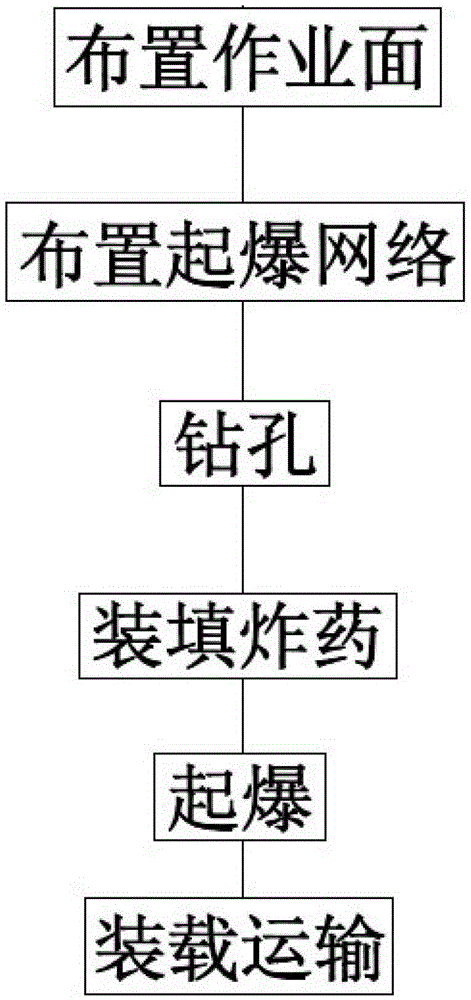

[0029] Such as figure 1 A stripping construction method for open-pit coal mining in the plateau area shown, including the following steps in turn:

[0030] (1) Arranging the working surface: The mining area is divided into several layers of working surfaces along the slope of the covering layer, and the vertical height of each layer of working surface is 10 meters. The vertical height of each layer of working face is the maximum height of the excavator’s digging capacity, and the entire mining area is divided into several working faces. Each working face can be constructed simultaneously under the condition of ensuring construction safety, which improves the construction efficiency and shortens the working time. deadline.

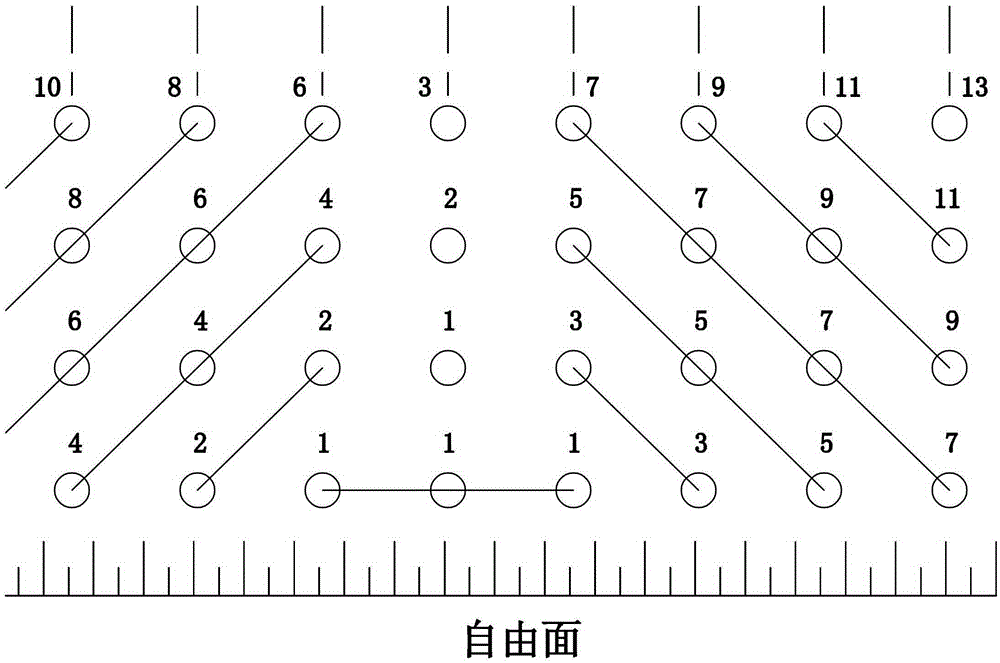

[0031] (2) Arranging the detonation network: arrange the detonation network on the working surface, the detonation network is a differential blasting detonation network, such as figure 2 As shown, the detonation network includes several blastholes arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com