Accuracy-variable magnetic railing ruler based on array nozzle electro-spinning direct writing and device and method for manufacturing accuracy-variable magnetic railing ruler

A technology of electrospinning direct writing and manufacturing method, which is applied in the processing and manufacturing of micro-nano level displacement sensing monitoring tools, micro-nano three-dimensional rapid prototyping, and achieves the effects of high processing precision, high adsorption performance, and uniform distribution of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

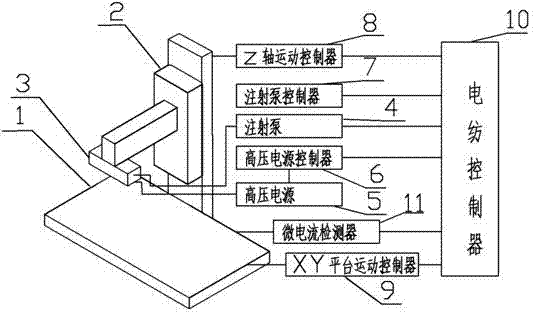

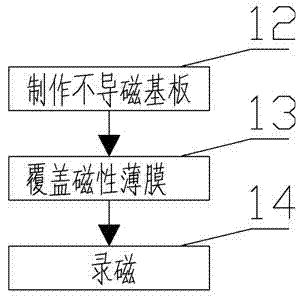

[0028] The structure diagram of the present invention based on the array nozzle electrospinning direct writing precision variable magnetic scale is as follows Image 6 As shown, it includes a non-magnetic film substrate and a magnetic film, the magnetic film is covered on the non-magnetic film substrate, and magnetic recording is made on the magnetic film to form a magnetic scale.

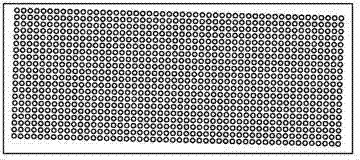

[0029] The above variable precision magnetic scale has a uniform elastic structure.

[0030] The non-magnetic film substrate and the magnetic film deposition material are the same, the deposition structure is the same, and the deposition distribution is uniform.

[0031] The above-mentioned non-magnetic film substrate is a non-magnetic film formed by orderly depositing non-magnetic polymers through multi-nozzle electrospinning; the magnetic film is formed by mixing the same polymer with hard magnetic material particles and then passing through array nozzles near-field electrospinning to form a non-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com