Fiber Bragg grating pressure sensor capable of monitoring positive and negative pressure and testing method

A pressure sensor and fiber grating technology, applied in the sensor field, can solve the problems of high Bourdon tube processing accuracy, difficult fiber grating packaging, large size of small-scale sensor, etc., to save manpower, facilitate parts processing, and improve sensitivity. and the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

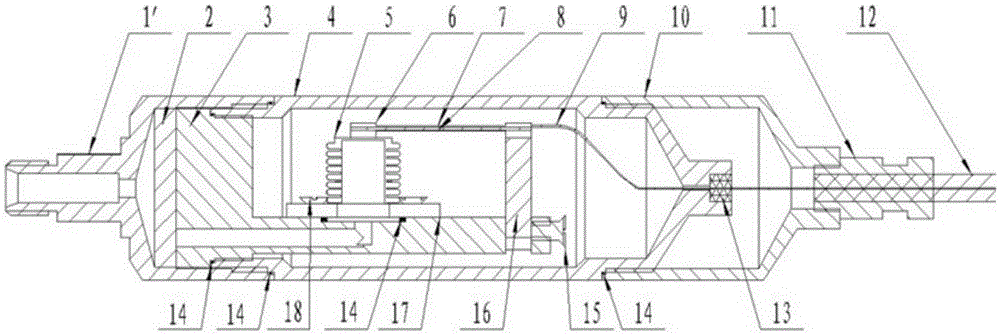

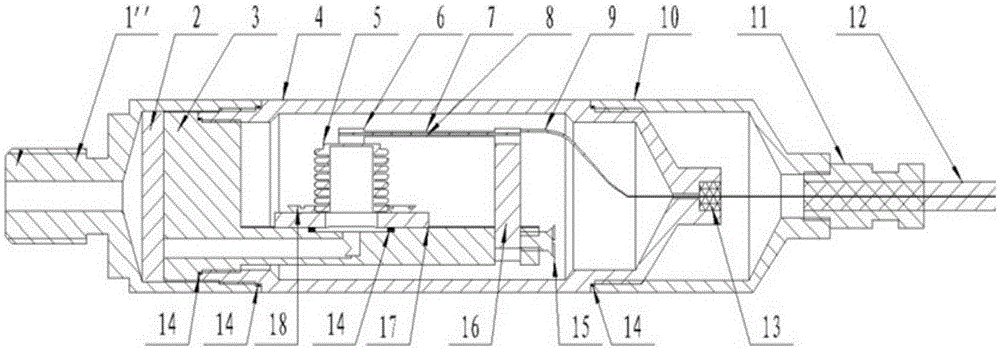

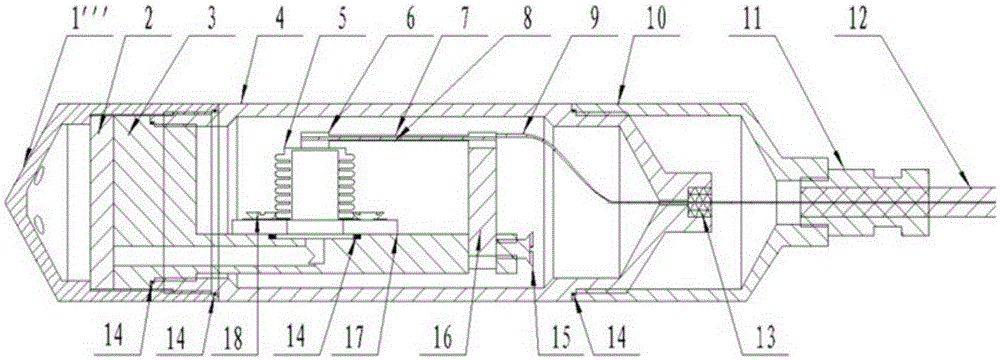

[0049] Such as Figure 1-Figure 4 As shown, a bellows structure fiber grating pressure sensor that can realize positive and negative pressure monitoring, the main part of the sensor includes:

[0050] The ferrule interface joint 1' is used to detect the coal seam gas pressure after connecting its supporting connection structure.

[0051] Standard connector 1'', can be directly connected to the pressure pipe to be measured.

[0052] Inserted connector 1''', which can be directly placed in the pressure-tight space to be measured.

[0053] The filter screen 2 is a powder metallurgy sintered screen, which is used to filter gas and liquid impurities to prevent internal blockage of the sensor.

[0054] The base 3 provides a fixed platform for bellows, flanges and pillars.

[0055] The shell 4 is used to create a closed space and at the same time protect the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com